Mold insert protective device and mold

A technology of protective devices and mold cores, which can be applied to home appliances, other home appliances, optical components, etc., and can solve problems such as optical lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

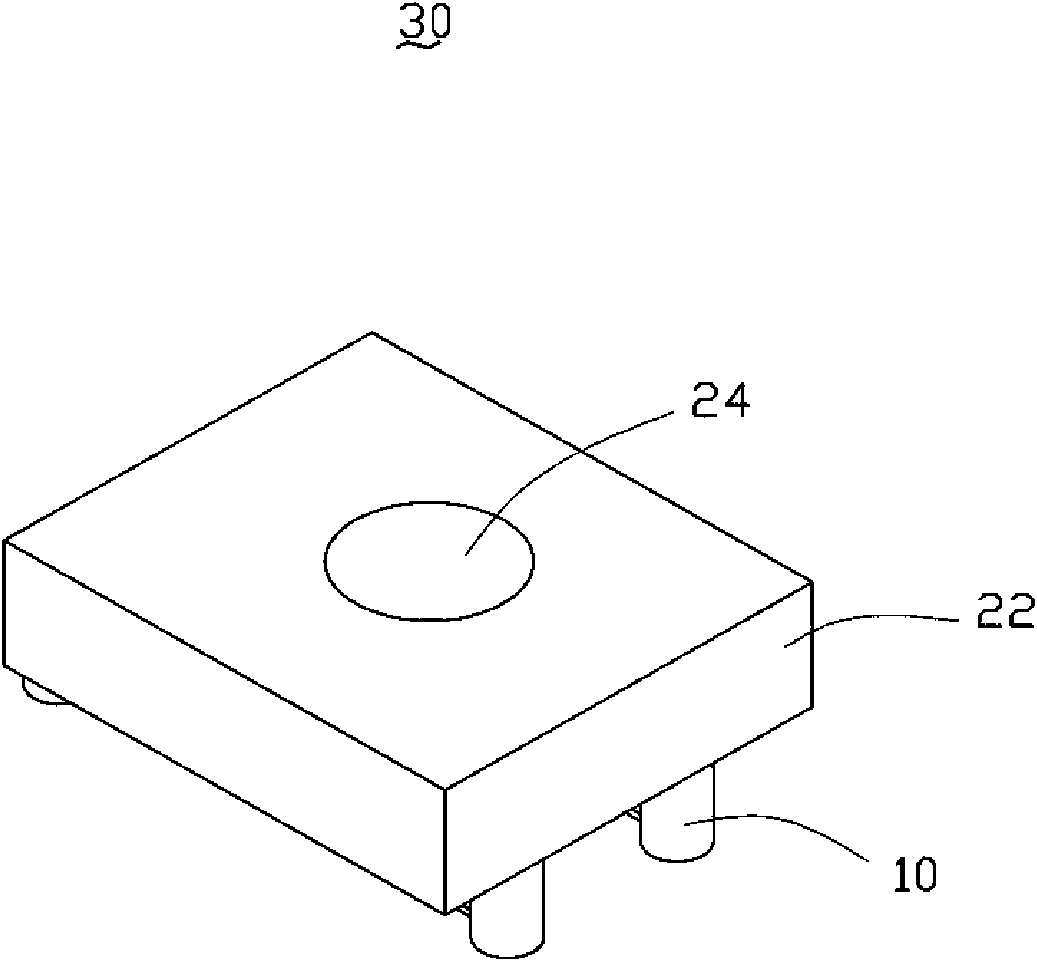

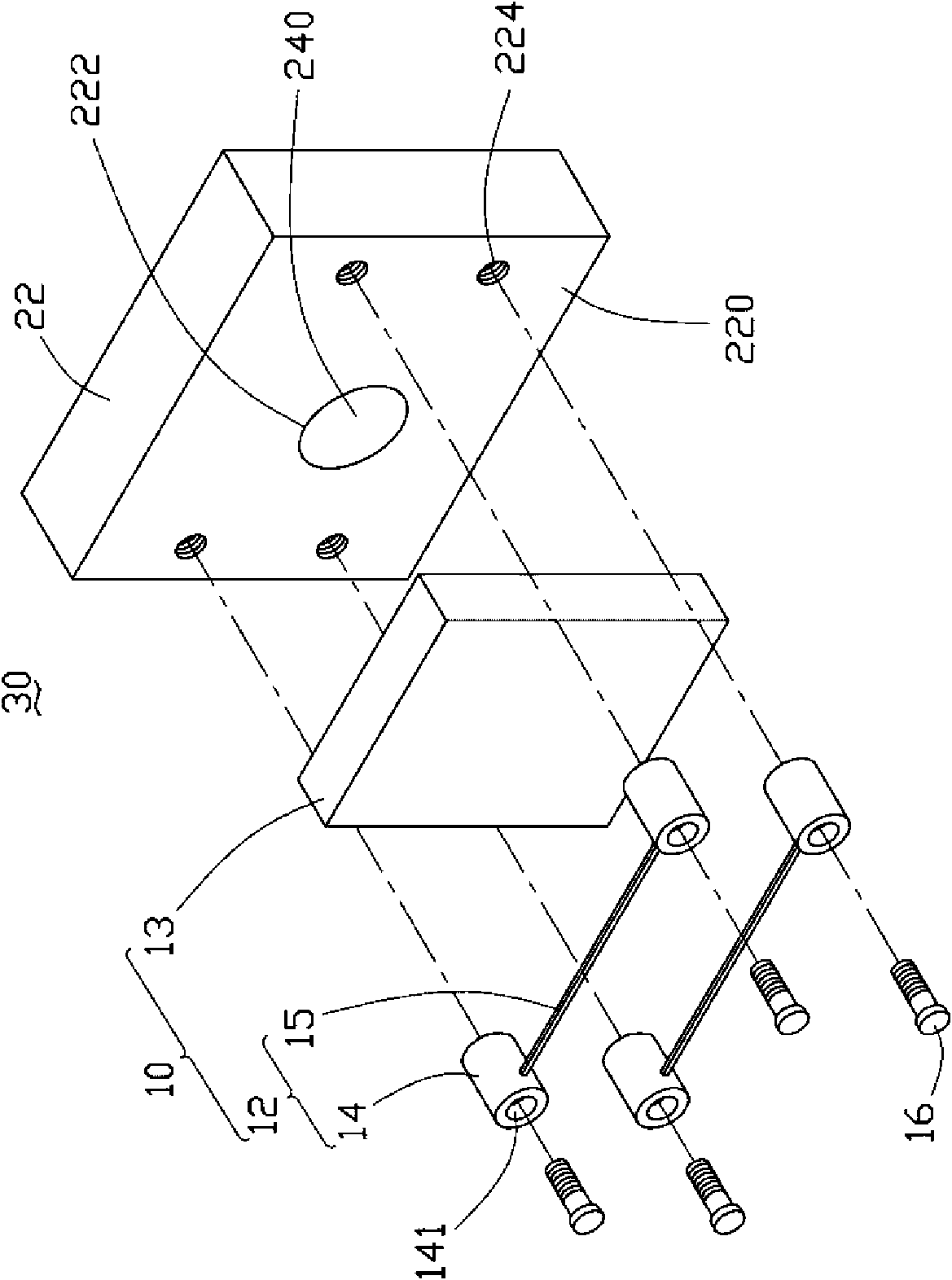

[0014] Please also refer to figure 1 and figure 2 , which is the mold 30 provided by the first embodiment of the present invention, which includes the mold core protection device 10 , the template 22 and the mold core 24 installed on the template 22 . Wherein, the mold core protection device 10 is fixed on the template 22, and is used to protect the molding surface 240 of the mold core 24 installed on the template 22 from being polluted by external impurities and impacted by other objects.

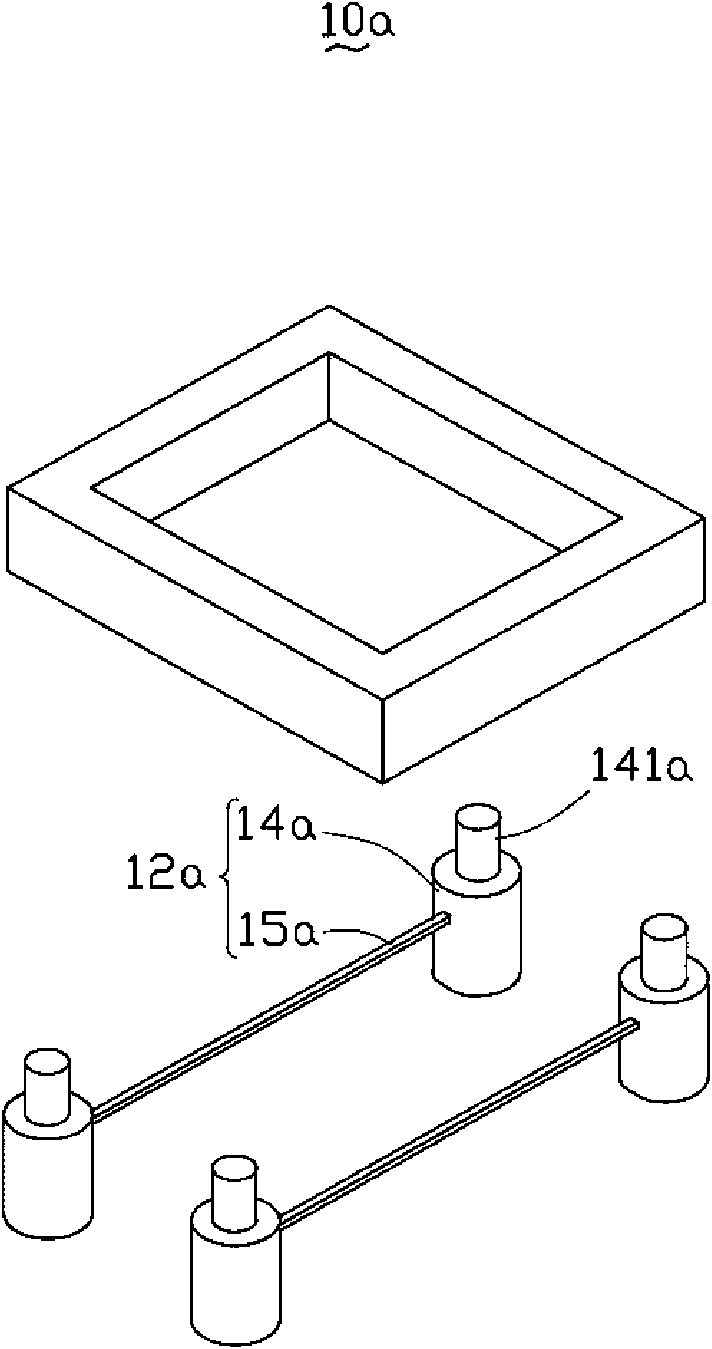

[0015] The mold core protection device 10 has two fixing pieces 12 and a cylindrical protective cover 13 with one end open. The fixing member 12 fixes the protective cover 13 relative to the template 22 , and has two cylindrical fixing bodies 14 and a fixing beam 15 located on the two fixing bodies 14 . The fixing body 14 has a first screw hole 141 passing through the fixing body 14 along the length direction of the fixing body 14 . In this embodiment, the fixing body 14 is a cylinder,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com