High-accuracy and portable micro-hardness detection device of boiler water

A boiler water and high-accuracy technology, which is applied in the direction of chemical analysis by titration, can solve the problems of inability to accurately judge whether the boiler condenser tube is leaking, low accuracy of on-site detection results, and difficulty in microhardness detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

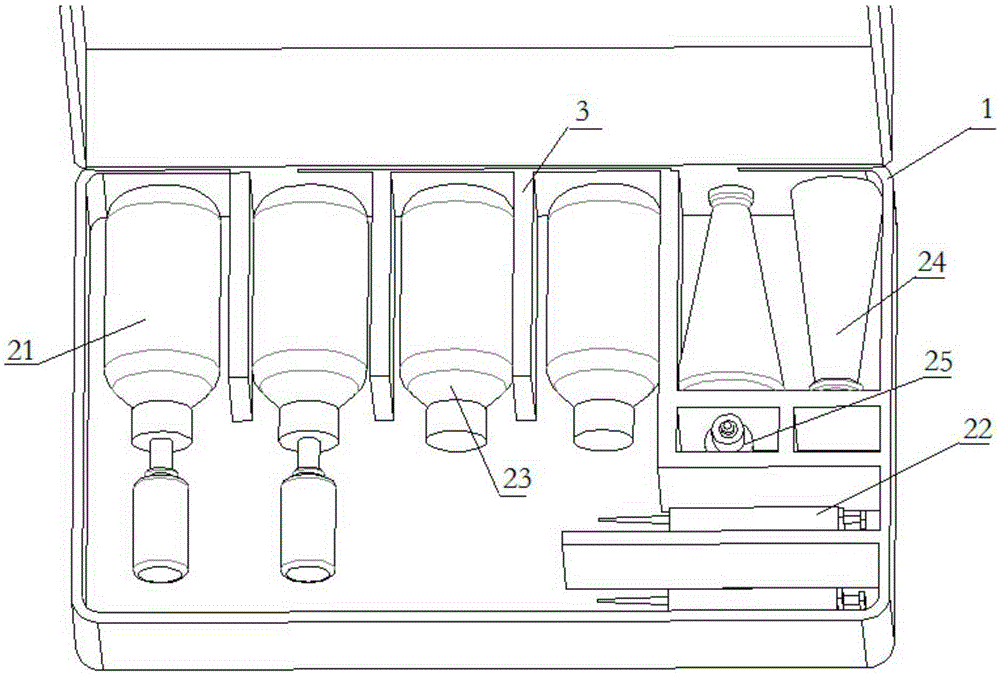

[0024] like figure 1 As shown, a high-accuracy portable boiler water microhardness detection device includes a box body 1 and a hardness test unit 2, the hardness test unit 2 is placed in the box body 1, and the casing of the box body 1 is made of flame retardant The plate is processed into a size of 500mm×300mm×250mm. The color of the inner plate of the box 1 is white, which is used as the colorimetric bottom plate for the titration operation. Instructions for operation steps are convenient for step-by-step query.

[0025] The hardness testing unit 2 includes a liquid addition bottle assembly 21 , a micropipette 22 , a sampling bottle 23 , a conical flask 24 and a test reagent bottle 25 .

[0026] The device also includes a shockproof lining 3 , which is filled in the mutual gaps between the liquid addition bottle assembly 21 , the micropipette 22 , the sampling bottle 23 , the conical flask 24 and the test reagent bottle 25 . The shockproof lining 3 can be made of foam, sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com