L-shaped unilateral lock wall structure and construction method

A lock wall and L-shaped technology, applied in the L-shaped single-side lock wall structure and construction field, can solve the problem of narrow layout of ship locks and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

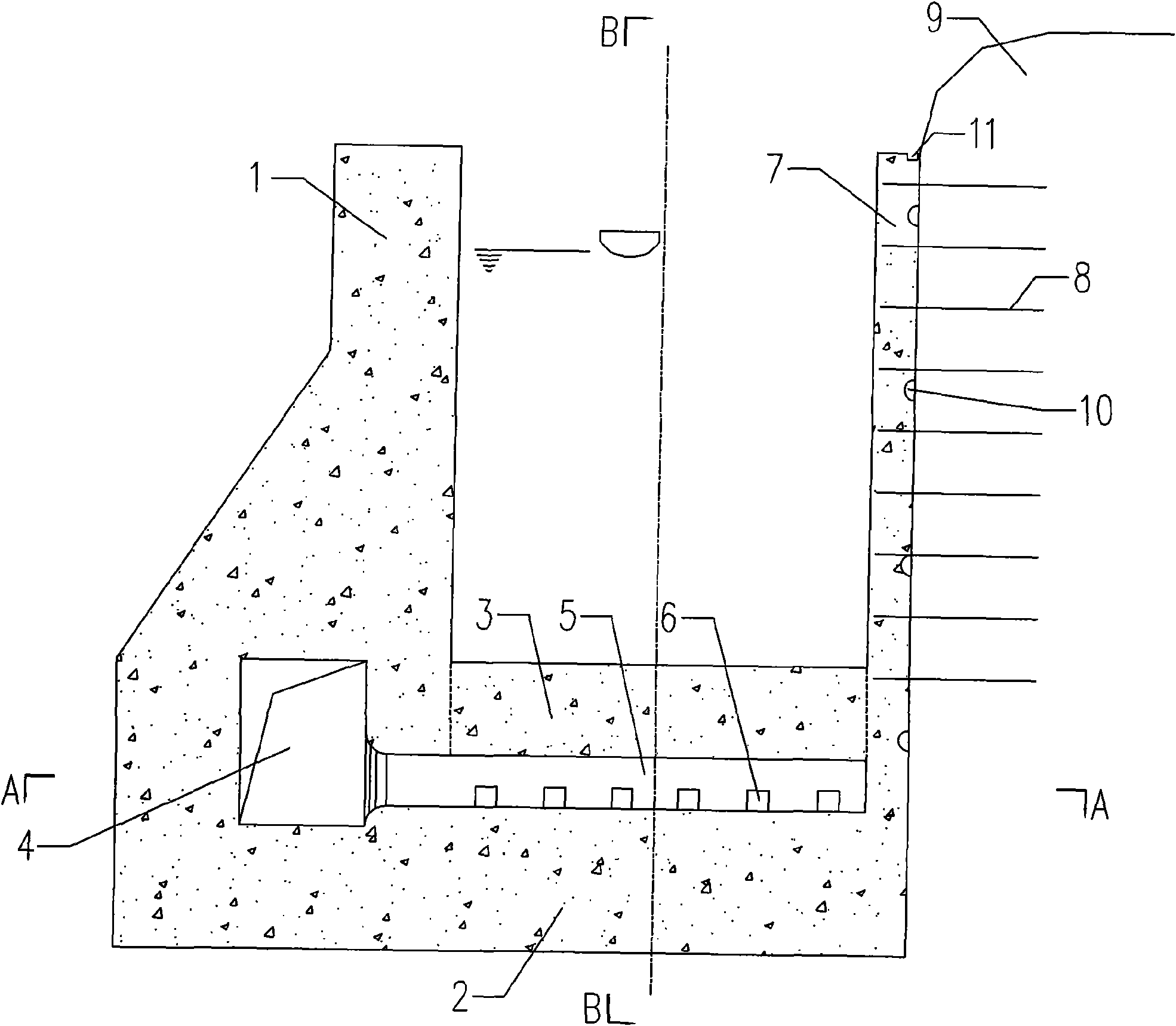

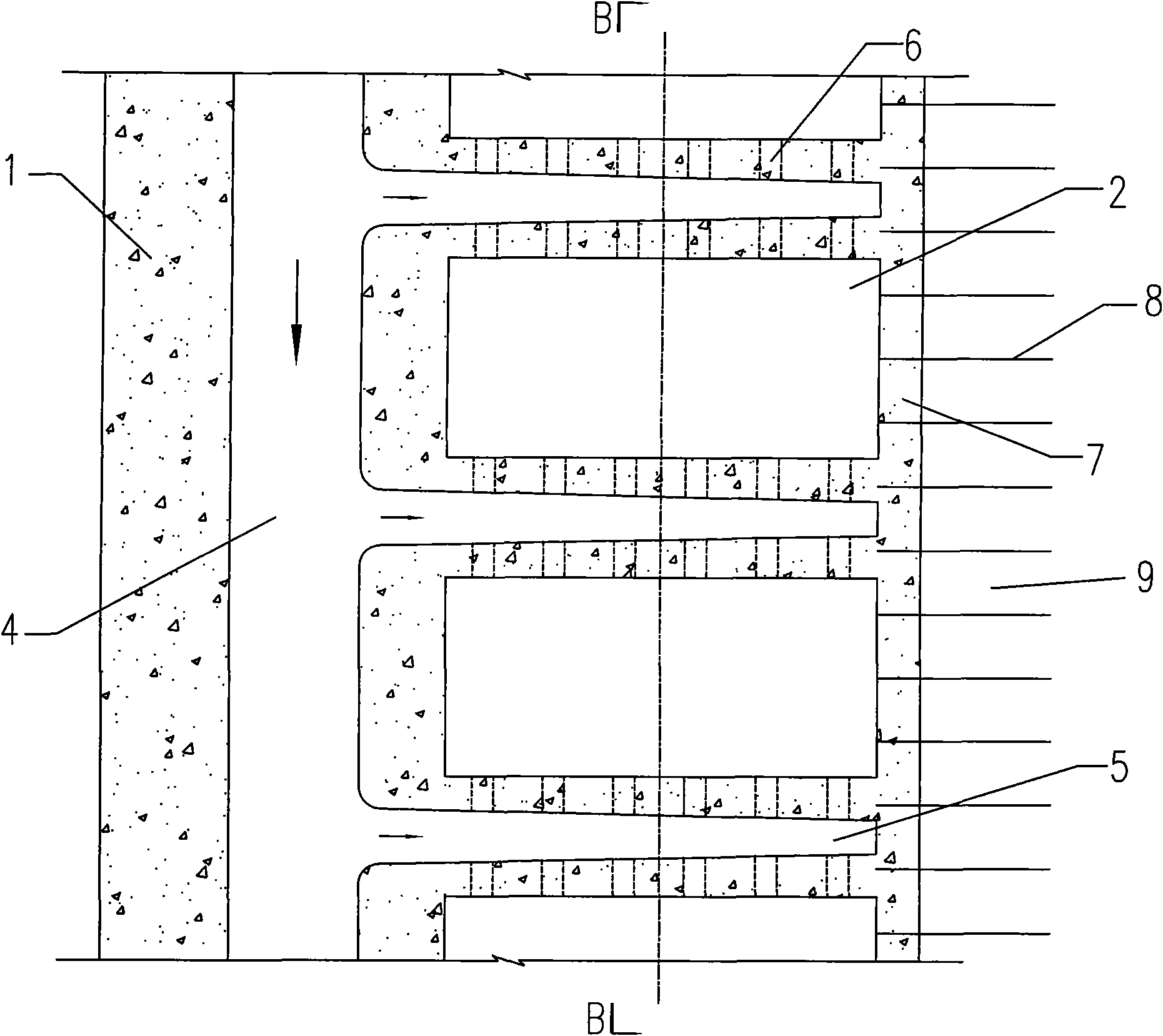

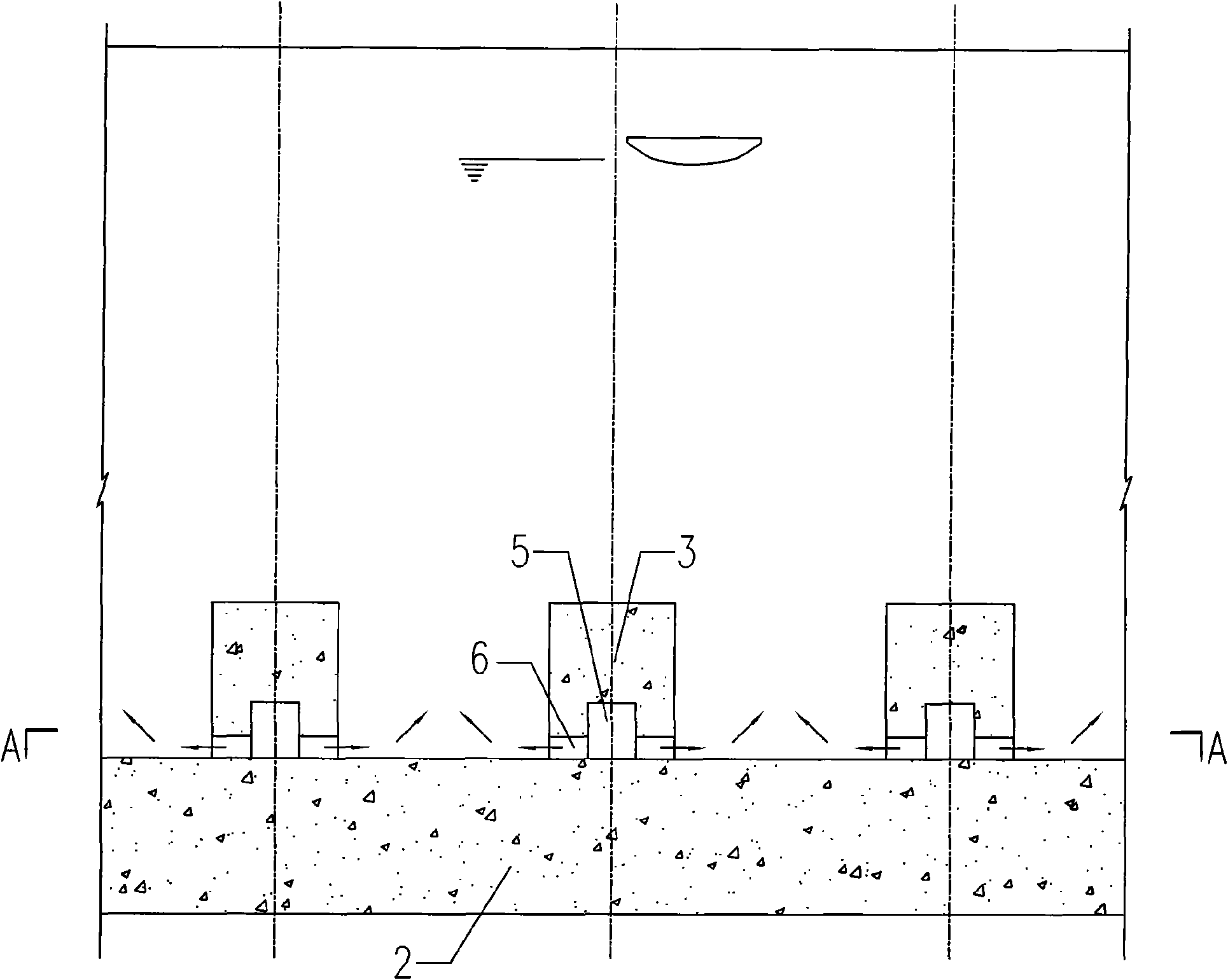

[0023] like figure 1 , figure 2 , image 3 As shown, in this embodiment, an L-shaped gate wall is formed by a single-side gate wall 1 and a lock chamber floor 2. The single-side gate wall 1 adopts a concrete structure, and the main water delivery corridor 4 is arranged in it, and the rock mass slope 9 is The slope is cut and the concrete lining wall 7 is arranged, which is integrated with the lock chamber bottom plate 2 to form a double-sided gate wall structure. The width of the top of the concrete lining wall 7 is not less than 2m, and a drainage ditch 11 is arranged at the top rock mass slope foot of the lining wall. In this example, the top plate 3 of the lock chamber is set on the bottom plate 2 of the lock chamber to form a group of energy dissipation structures. A horizontal branch corridor 5 is arranged between adjacent energy dissipation structures. The main water delivery corridor 4 and the horizontal branch corridor 5. Trumpet-shaped formwork is used for smooth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com