Multi-camera movable photography measuring method in vibration environment

A measurement method and dynamic photography technology, applied in the field of measurement, can solve the problems of error, the position relationship of multiple cameras cannot be kept fixed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

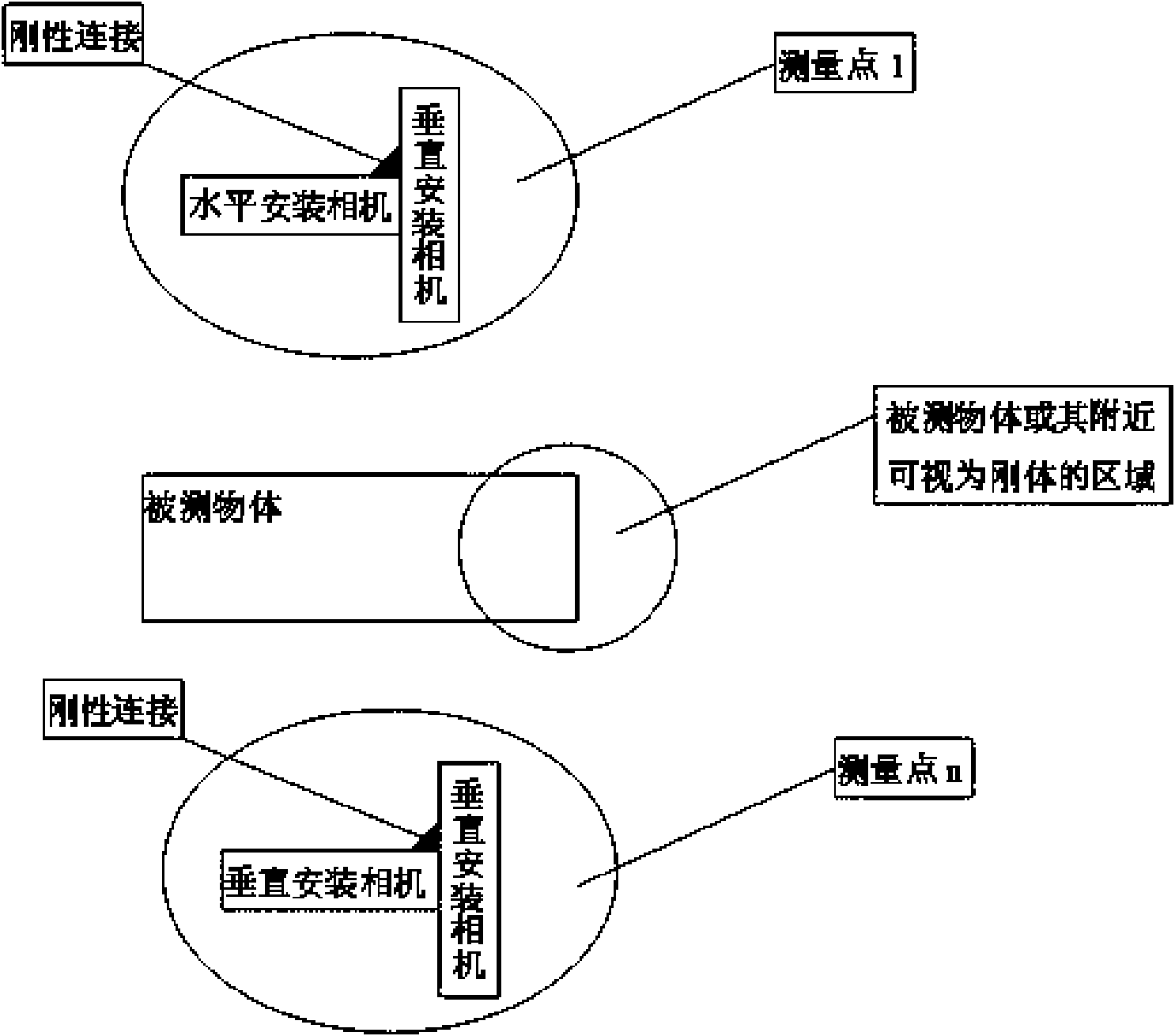

[0018] Such as figure 1 As shown, the specific embodiment of the multi-camera dynamic photogrammetry method in the vibration environment of the present invention includes the following steps:

[0019] a. First, find out the part that does not deform during the measurement process on or near the measured object, that is, the area that is regarded as a rigid body, and paste the coded marking points in the area regarded as a rigid body. The number of coded marking points is greater than or equal to 4 , and the printed coding marks are not in the same plane;

[0020] b. In a vibration-free environment, use static digital industrial photogrammetry technology to measure the three-dimensional coordinates of the sticky-printed code marking points on the area regarded as a rigid body;

[0021] c. In a vibration-free environment, use static digital industrial photogrammetry technology to calibrate the inner orientation elements of multiple cameras;

[0022] d. In a vibrating environme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com