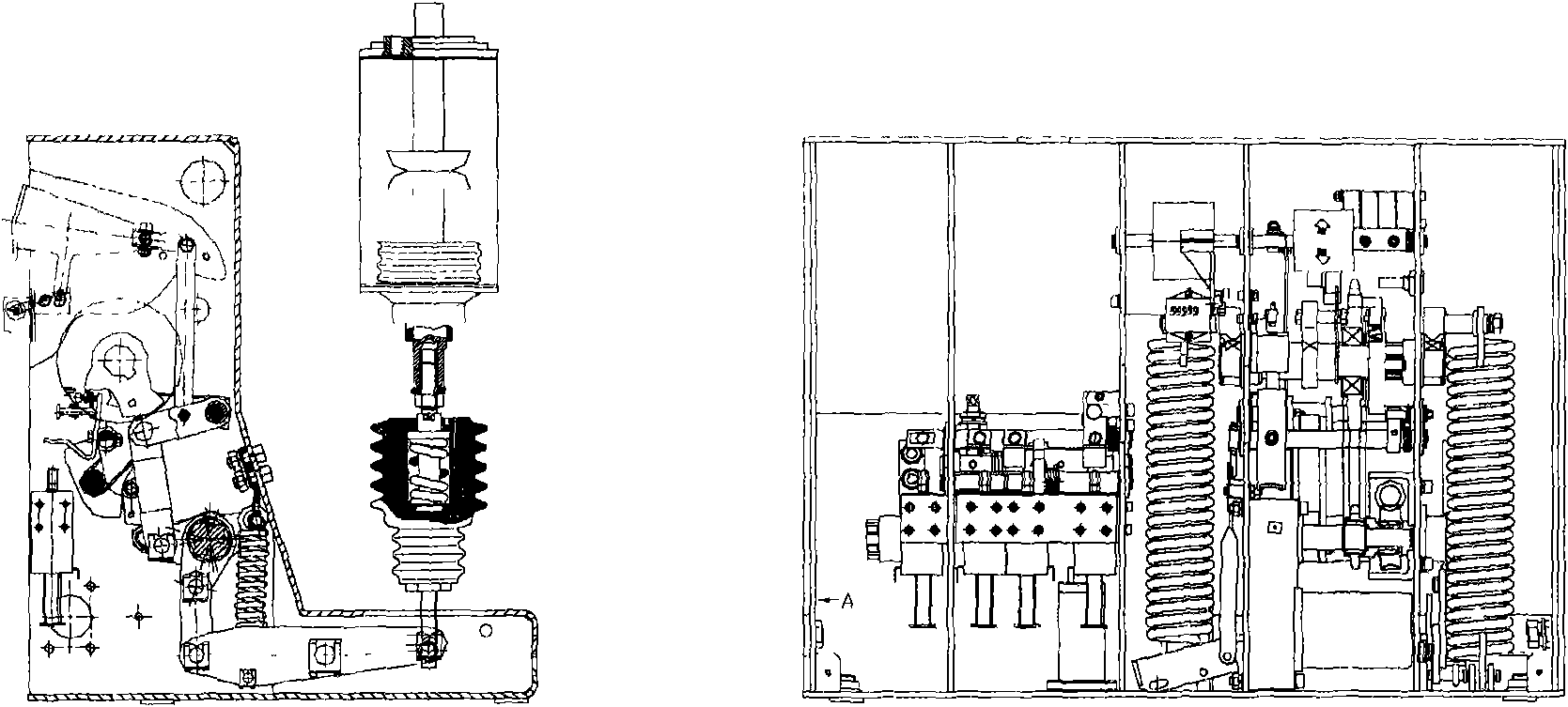

Spring operating mechanism

A technology of operating mechanism and pushing part, applied in the direction of high-voltage air circuit breakers, electrical components, electric switches, etc., can solve the problems of inconvenient replacement, easily damaged closing coil, large size, etc., to achieve easy replacement and maintenance, structural Reasonable layout and miniaturization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described more fully hereinafter with reference to the accompanying drawings, in which exemplary embodiments of the invention are illustrated.

[0020] figure 2 It is a structural front view of an embodiment of the spring operating mechanism according to the present invention. like figure 2 As shown, the spring operating mechanism includes a left plate 17 of the mechanism, a right plate 20 of the mechanism and an intermediate partition 27 of the mechanism, and the intermediate partition 27 of the mechanism is fixed between the left plate 17 of the mechanism and the right plate 20 of the mechanism. The mechanism frame is divided into four areas by the mechanism left plate 17, the mechanism right plate 20 and the mechanism middle partition plate 27. From left to right, they are: energy storage part, closing part, opening part and secondary lead part. This mechanism is bolted with mechanism frame by mechanism left plate 17 and mechanism ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com