Insulating enclosed type pagoda-shaped fuse

A fuse and pagoda-type technology, which is applied in the field of insulated and closed pagoda-type fuses, can solve the problems of reduced safety of live work, reduction of electricity sales, explosion, etc., and achieve improved safety of live work, improved safety performance of live work, Damage mitigation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

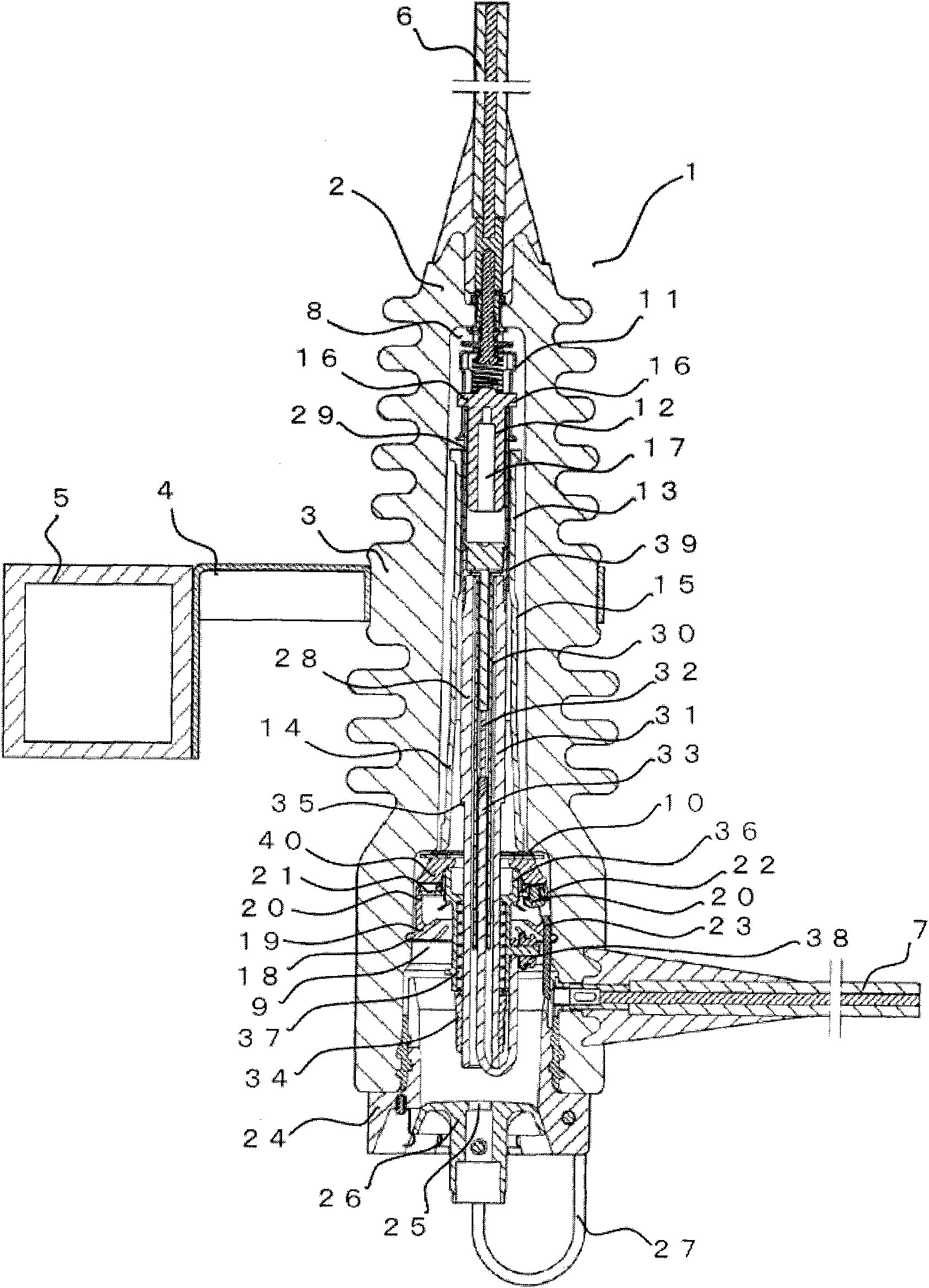

[0051] An insulator body 2 of an insulated closed pagoda-shaped fuse 1 is formed into a cylinder shape by porcelain, and a plurality of upper ribs are formed on the upper part of the insulator body 2, and a fitting installation part 3 and a plurality of lower protrusions are formed on the body part. The rib forms a cylindrical portion at its lower portion. The mounting part 3 of the fitting fittings forms a thick-walled porcelain wall, and its wall thickness is in the range of 30-40mm, so that its outer diameter is approximately the same as that of the upper protrusion.

[0052] Mounting fittings 4 are installed on the mounting fittings installation part 3 , and the pagoda-shaped fuse 1 is fixed on the cross arm 5 of the electric column by the fittings 4 .

[0053] On the upper part of the insulator body 2, an upper lead-out wire 6 is fixed by a rubber tapered member. The lower lead-out wire is fixed on the lower part of the insulator body 2 through the rubber tapered part. ...

Embodiment 2

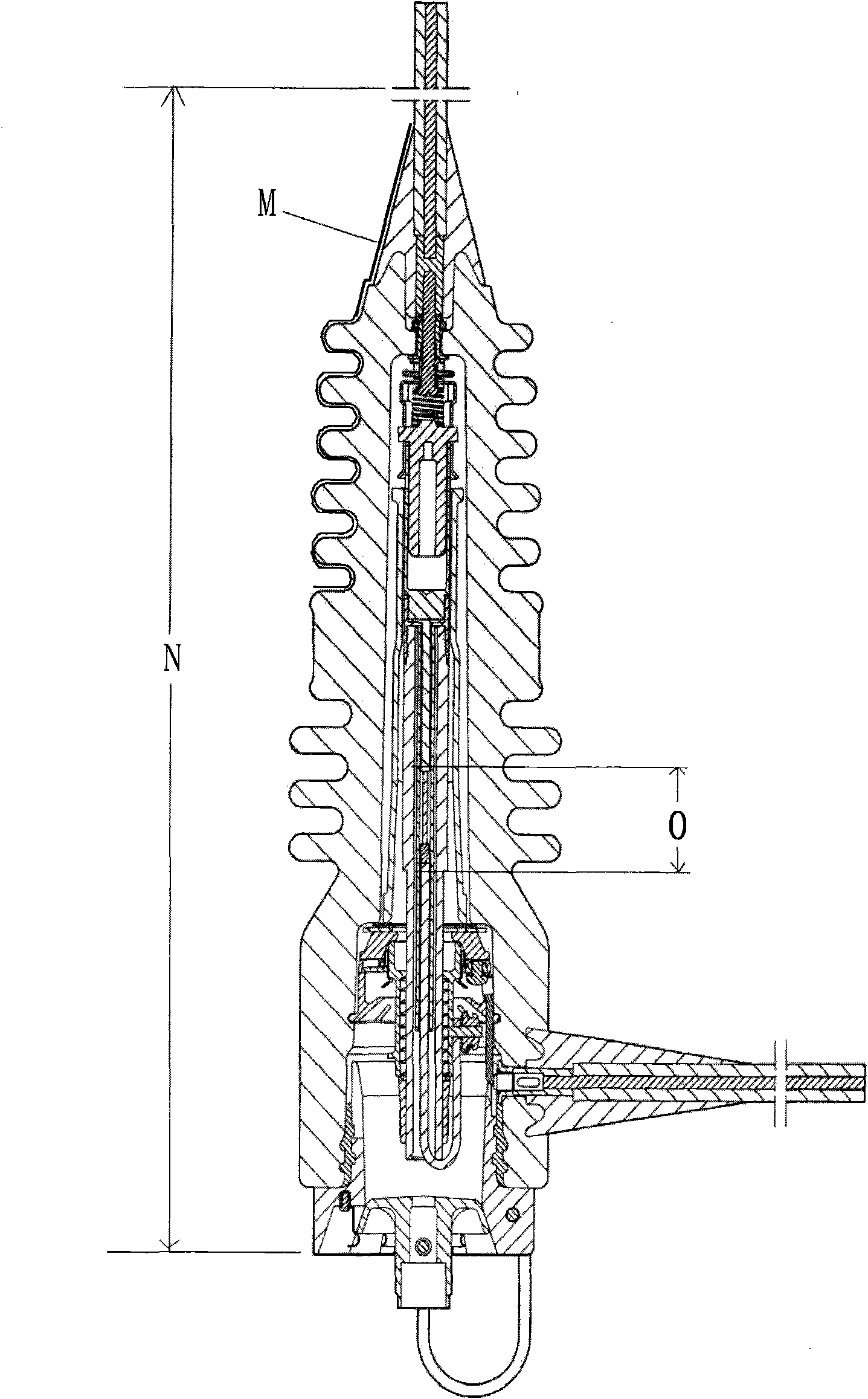

[0078] Except that the surface leakage distance M of the fuse is 385-400mm, the others are the same as in Embodiment 1, and the insulation-enclosed pagoda-shaped fuse of the present invention is obtained.

Embodiment 3

[0080] Except for the overall height of the fuse, that is, the distance N from the bottom of the entire fuse to the tapered top of the upper end is controlled to be 450-475mm. Except, other is the same as embodiment 1, makes the insulating closed type pagoda fuse of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com