Thermal shrinkage type composite casing tube for cable midst joint and manufacturing method thereof

A technology of cable intermediate joint and composite sleeve, which is applied to cable joints, circuits, electrical components, etc., can solve the problems of complicated cable installation process, partial discharge, low power frequency withstand voltage, etc., and achieves simple process and high safety. , the effect of high power frequency withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

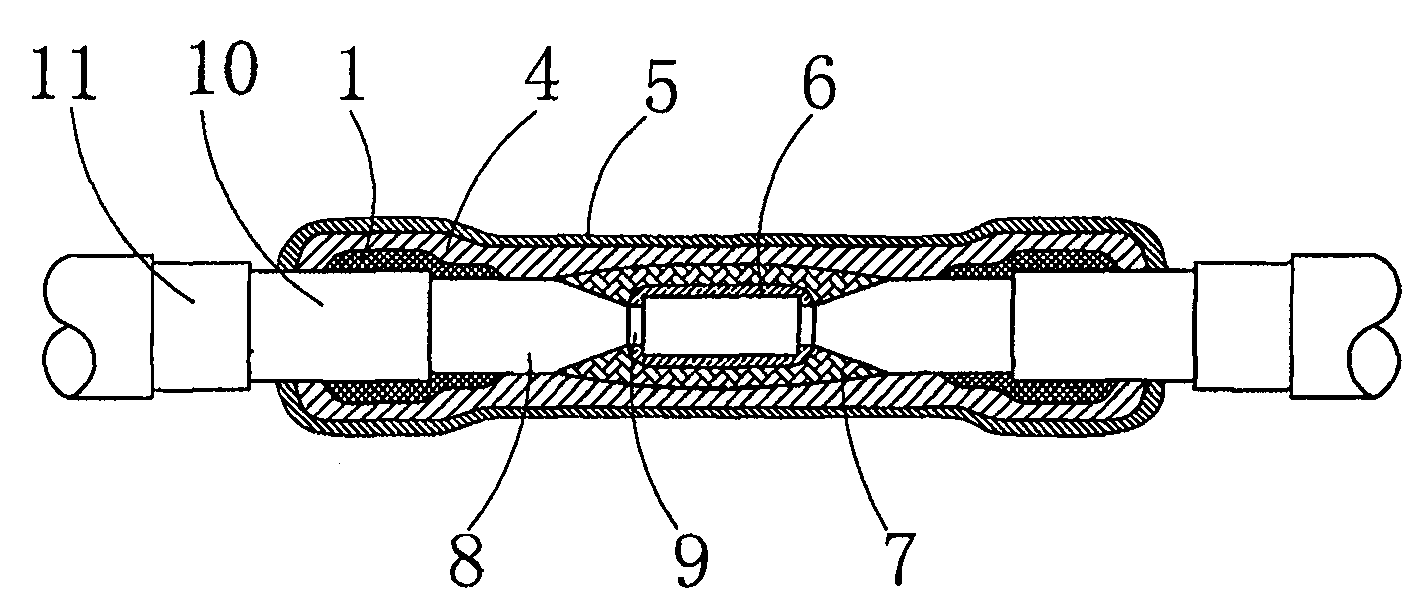

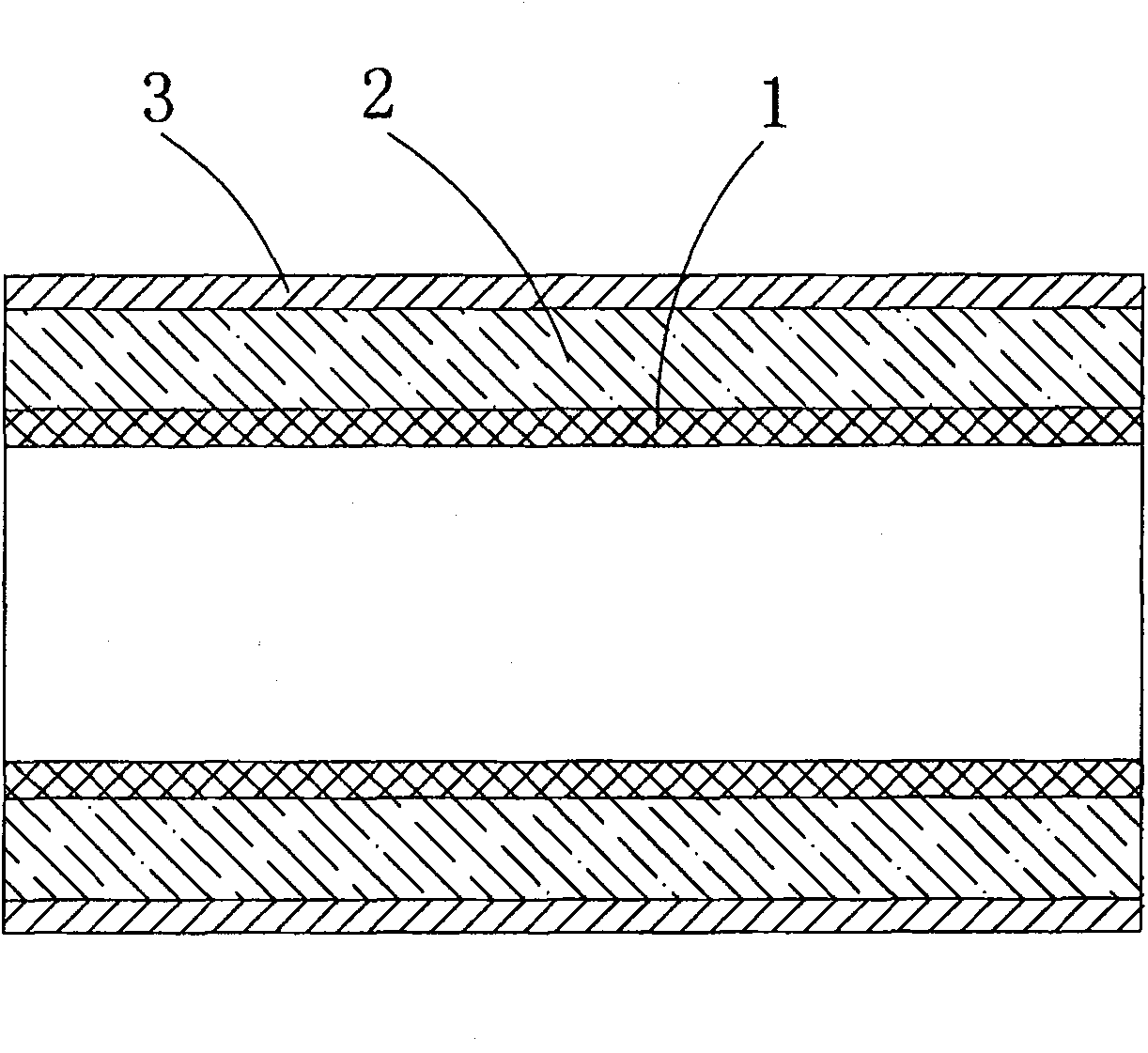

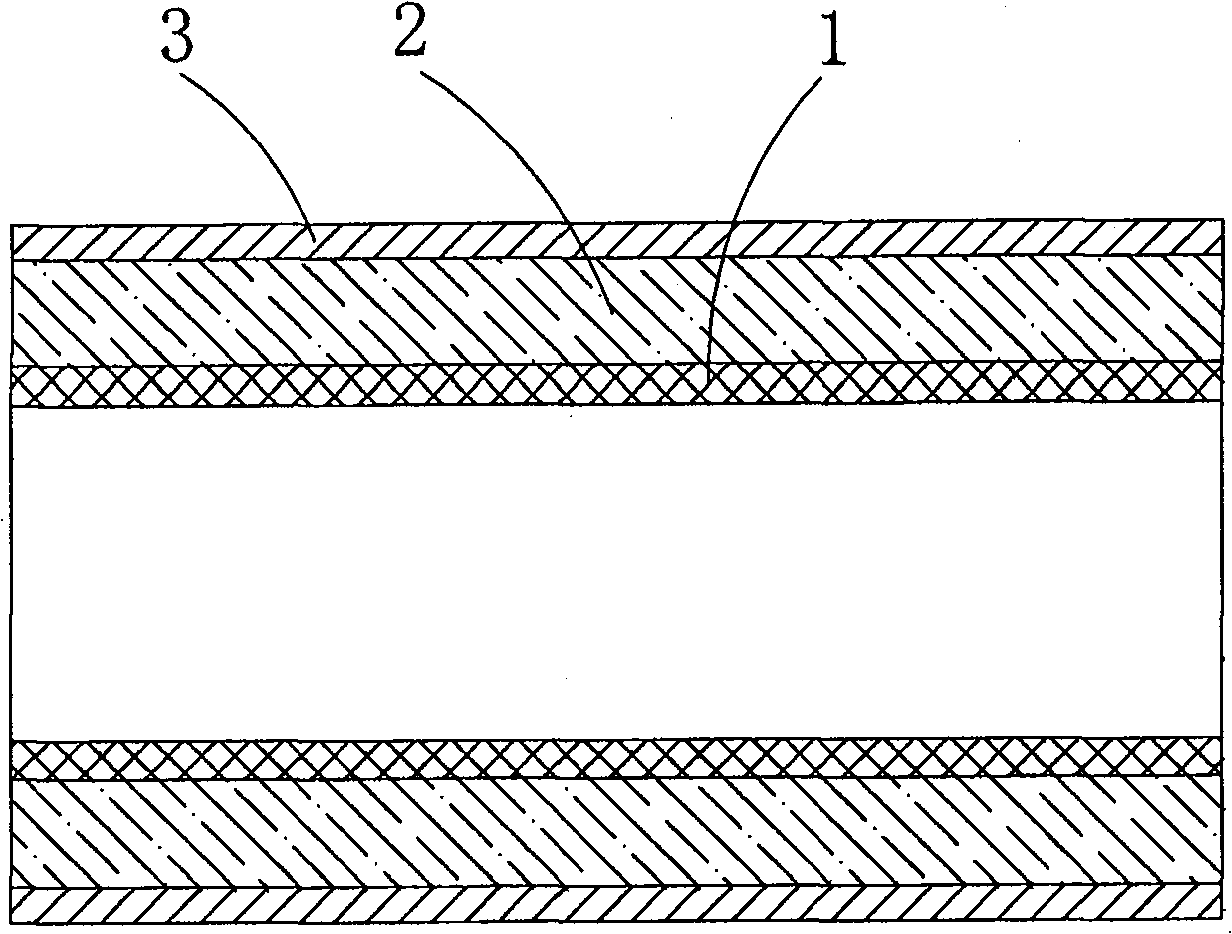

[0041] 8.7 / 15kV XLPE insulated power cable, core size 3×185mm 2 Take the cable intermediate joint composite sleeve as an example. Such as figure 2 As shown, the heat-shrinkable cable intermediate joint composite sleeve is in the shape of a round tube, and it has a three-layer composite structure. Conductive shielding layer 3 constitutes. The three layers are composed of three functional plastics of semi-conductive shielding, insulation and stress control respectively plasticized and co-extruded by a plastic extruder.

[0042] Wherein: the component of the material of stress control layer is (weight ratio): the EVA (VA=18%, MI=1.5) of 70 parts, the EPDM (4045) of 30 parts, 16 parts are made of conductive carbon black and high wear-resistant carbon Black is a combination of carbon black made of 1:3, 50 parts of BaTiO 3 (≥800 mesh), 1 part of antioxidant (1010), 1 part of silane coupling agent.

[0043] The material components of the insulating layer are (weight ratio): 33 ...

Embodiment 2

[0051] In this embodiment, the material composition of the stress control layer is (weight ratio): 50 parts of EVA (VA=18%, MI=1.5), 30 parts of EPDM, 20 parts of LDPE (MI=2.0), 16 parts of combined carbon Black (superfine grade), 52 parts BaTiO 3 (≥800 mesh), 1 part antioxidant (1010), 2 parts silane coupling agent.

[0052] The material composition of the insulating layer is (weight ratio): 25 parts of LDPE (MI=2.0), 10 parts of LLDPE (MI=1.5), 65 parts of EVA (VA=18%, MI=1.5), 15 parts of Al(OH) 3 After activation treatment, 1 part of antioxidant (1010), appropriate amount of toner.

[0053] The material composition of the semi-conductive shielding layer is (by weight) 30 parts of LDPE (MI=2.0), 60 parts of EVA (VA=18%, MI=1.5), 10 parts of POE, 30 parts of conductive carbon black (ultra-fine grade) , 1 part zinc stearate, 1 part antioxidant (1010);

[0054] The stress control layer, insulating layer and semi-conductive shielding layer are respectively plasticized with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com