Training system for identifying defects of display panel

A technology for displaying panel defects and training systems, which is applied to simulation devices, instruments, simulators and other directions of astronautical conditions, can solve the problems of increased risk of return and poor results, and achieves increased practice opportunities, shortened training periods, and improved training. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

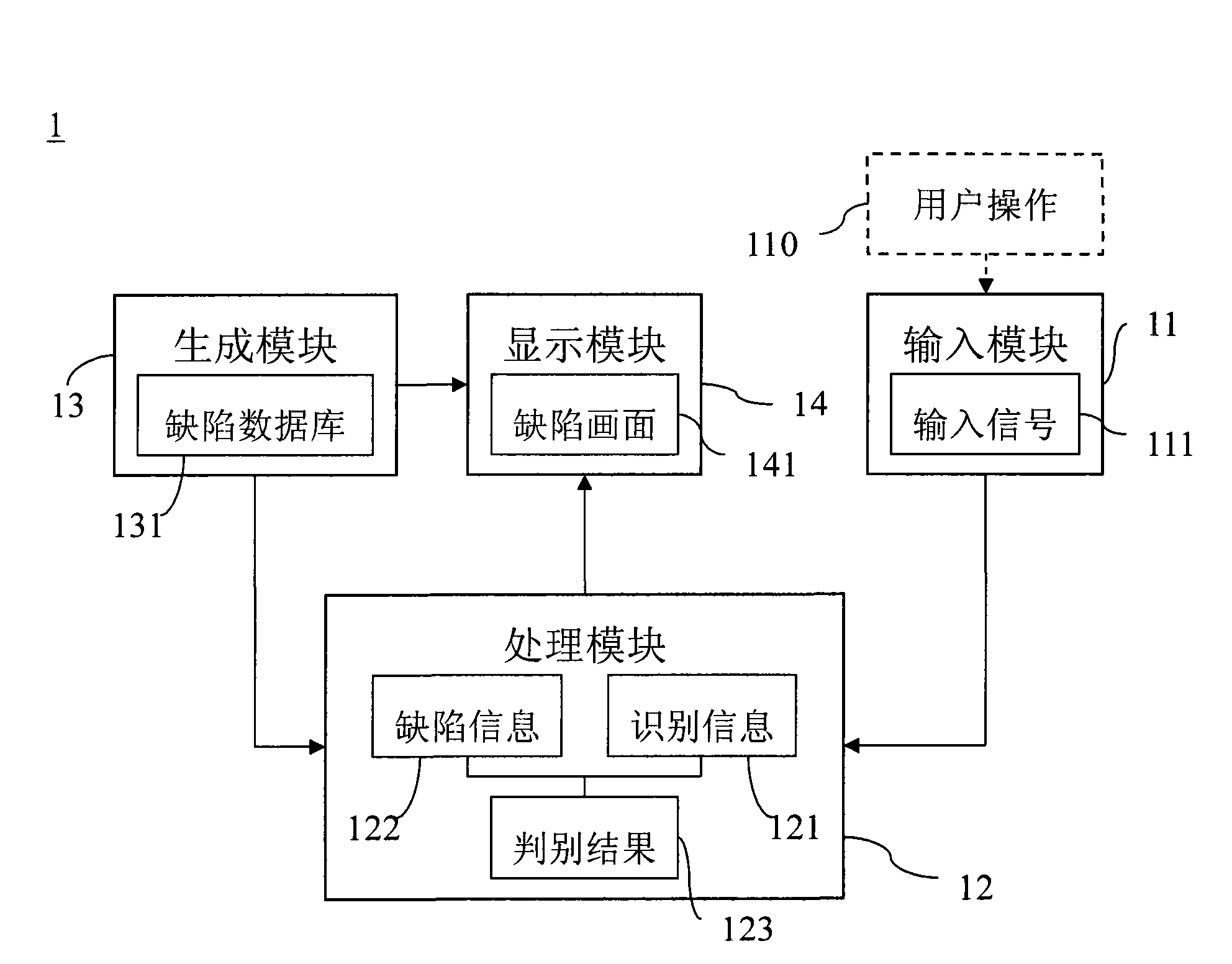

[0015] See figure 1 , figure 1 It is a block diagram of a training system for display panel defect recognition according to an embodiment of the present invention. The training system 1 for display panel defect recognition includes an input module 11 , a processing module 12 , a generation module 13 and a display module 14 . The input module 11 outputs an input signal 111 according to a user operation 110 . In one embodiment, the user operation 110 includes but not limited to keyboard input, mouse click, touch selection, and the like. The processing module 12 is connected to the input module 11 and generates identification information 121 according to the input signal 111 . The generating module 13 is connected to the processing module 12 and provides the defect i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com