Transferring platform of glass edge grinding machine

A glass edge grinding and bench technology, which is applied to machine tools, grinders, grinding/polishing equipment and other directions suitable for grinding workpiece edges, can solve the problems of slow transmission speed, complex structure and high failure rate, and achieves low cost, The effect of accurate transmission position and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

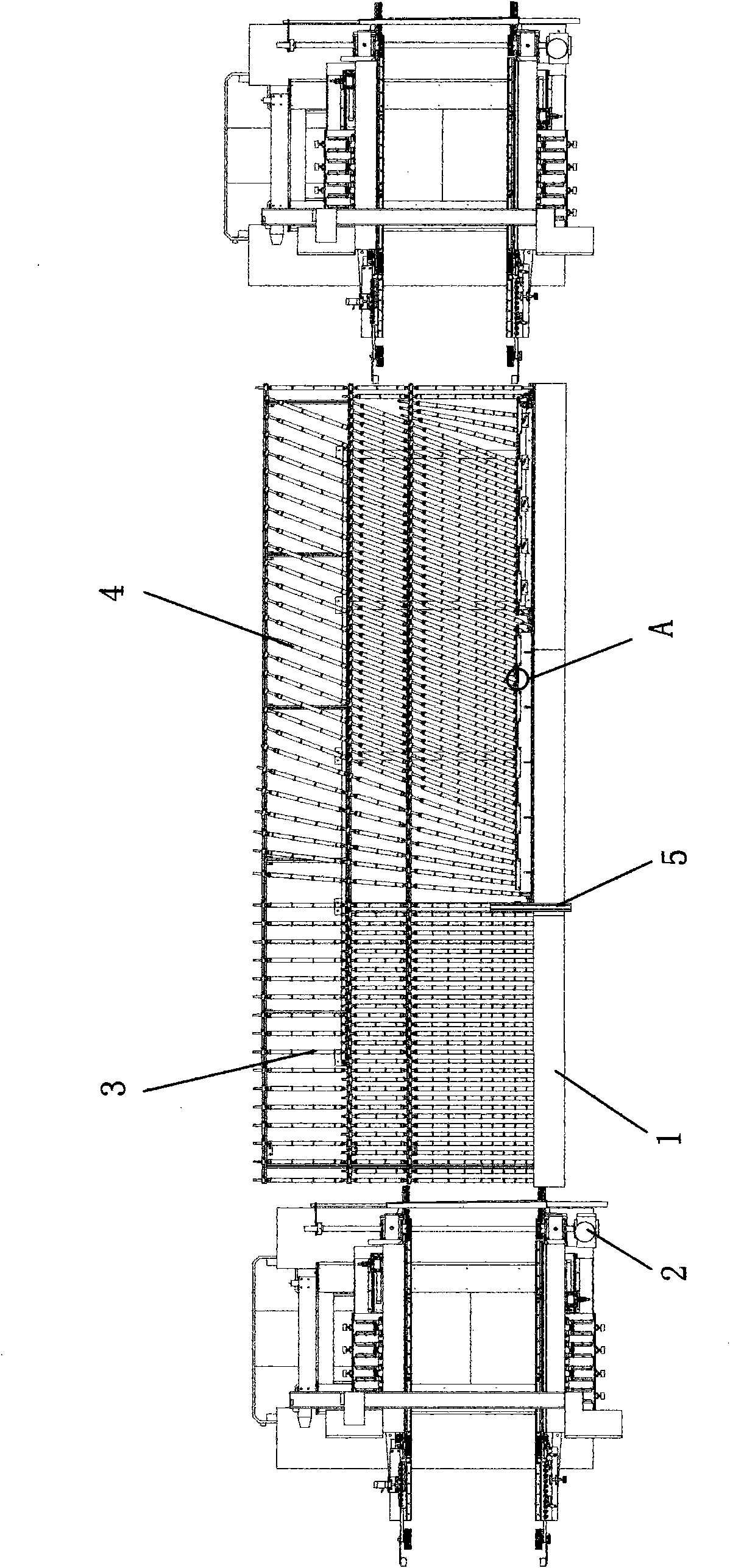

[0022] Such as figure 1 , 2 As shown, it includes a platform 1, a transfer mechanism set on the platform 1, and the transfer mechanism is driven by a motor 2. The transfer mechanism is divided into an entry area 3 and a turning area 4, between the entry area 3 and the turning area 4 Help steering rod 5 is arranged between.

[0023] The entry area 3 is composed of balanced transmission rollers, which are installed on the surface of the platform 1 and driven by a motor 2.

[0024] The turning area 4 is composed of fan-shaped drive rollers arranged on the surface of the platform 1 and driven by a motor 2.

[0025] For the fan-shaped drive rollers in the turning area 4, the angle between the drive rollers gradually increases from the first one.

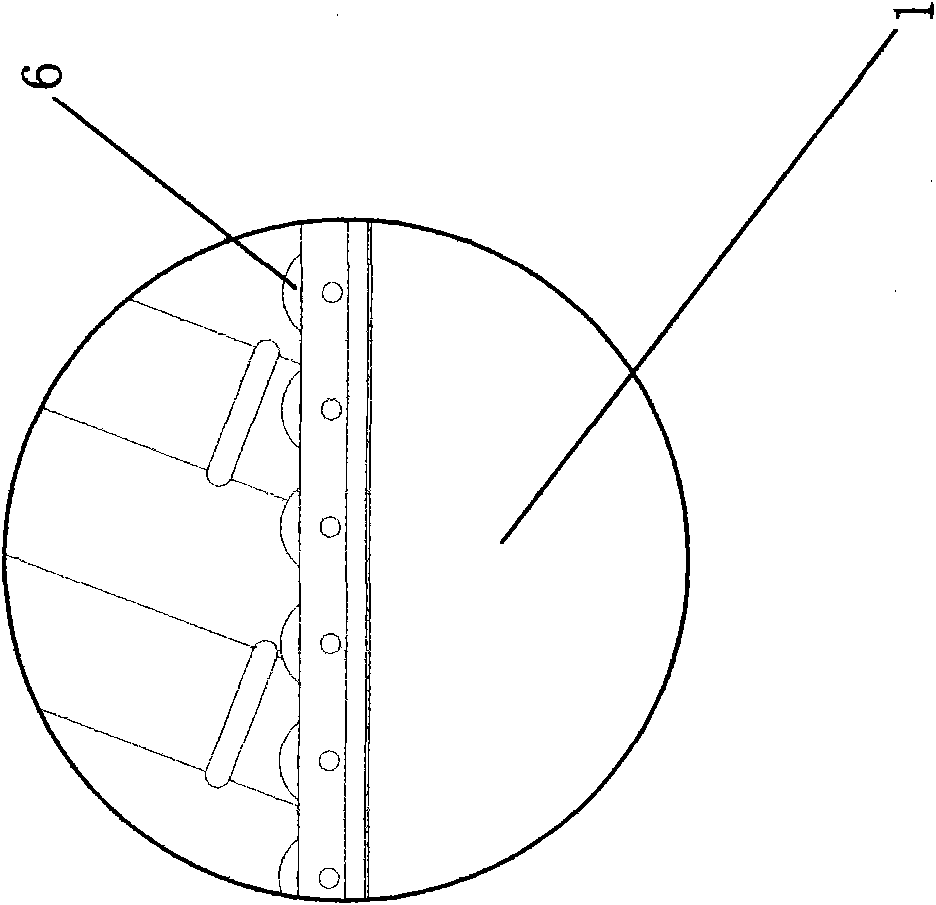

[0026] A guide wheel 6 is provided on the edge of the platform 1 on the side of the fan-shaped shaft core of the dr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap