Power line harness terminal fixing connection device and connection processing technology thereof

A terminal fixing and connecting equipment technology, applied in the direction of connection, circuit, electrical components, etc., can solve the problems of inaccurate terminal transmission position, deviation of pressure column extrusion position, fixation, etc., to prevent poor terminal cutting effect and increase precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0043] Such as Figure 8 As shown, the bottom of the commonly used wire harness terminal is a terminal frame, the terminal frame is uniformly provided with round holes, and the top of the terminal frame is uniformly provided with terminals, and the positions of the terminals correspond to the positions of the round holes on the terminal frame.

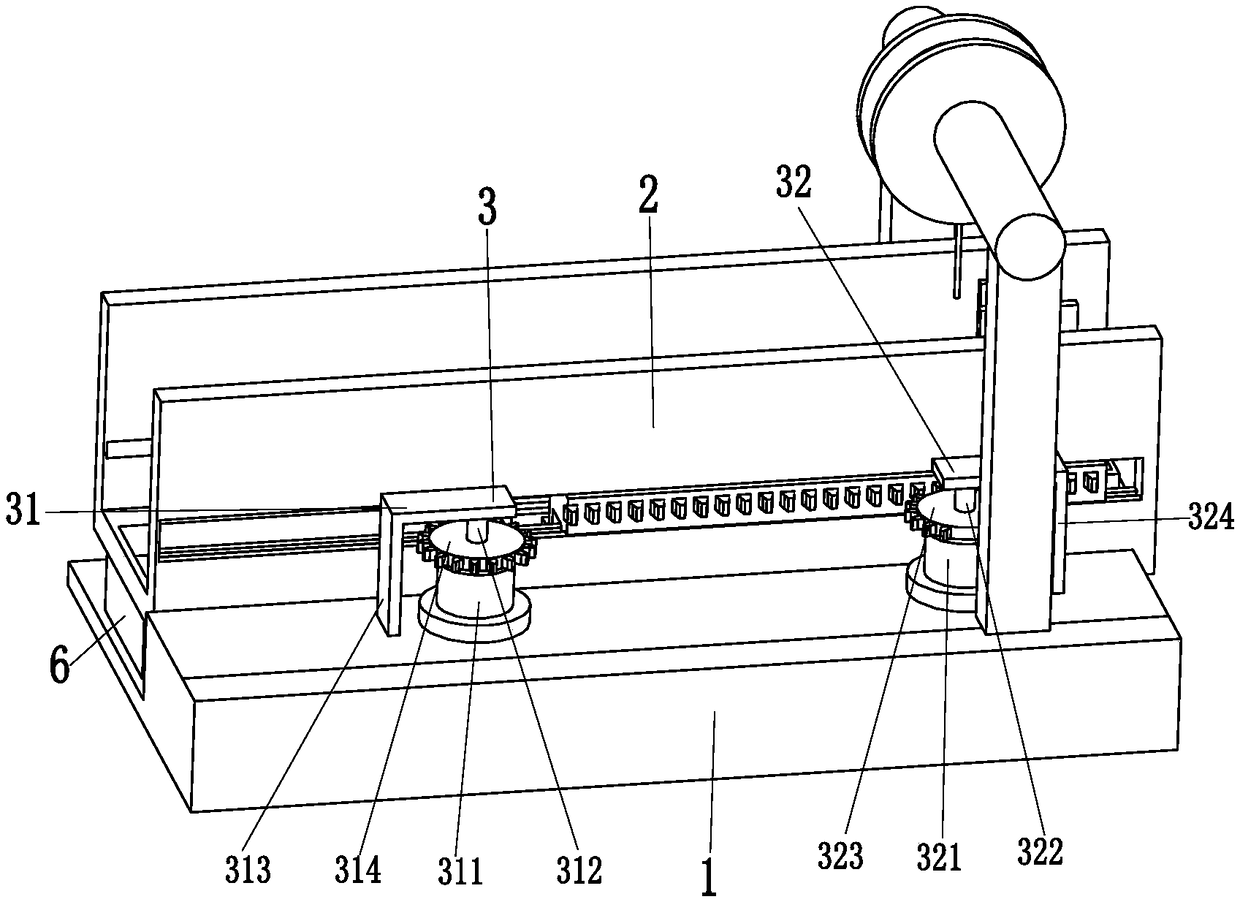

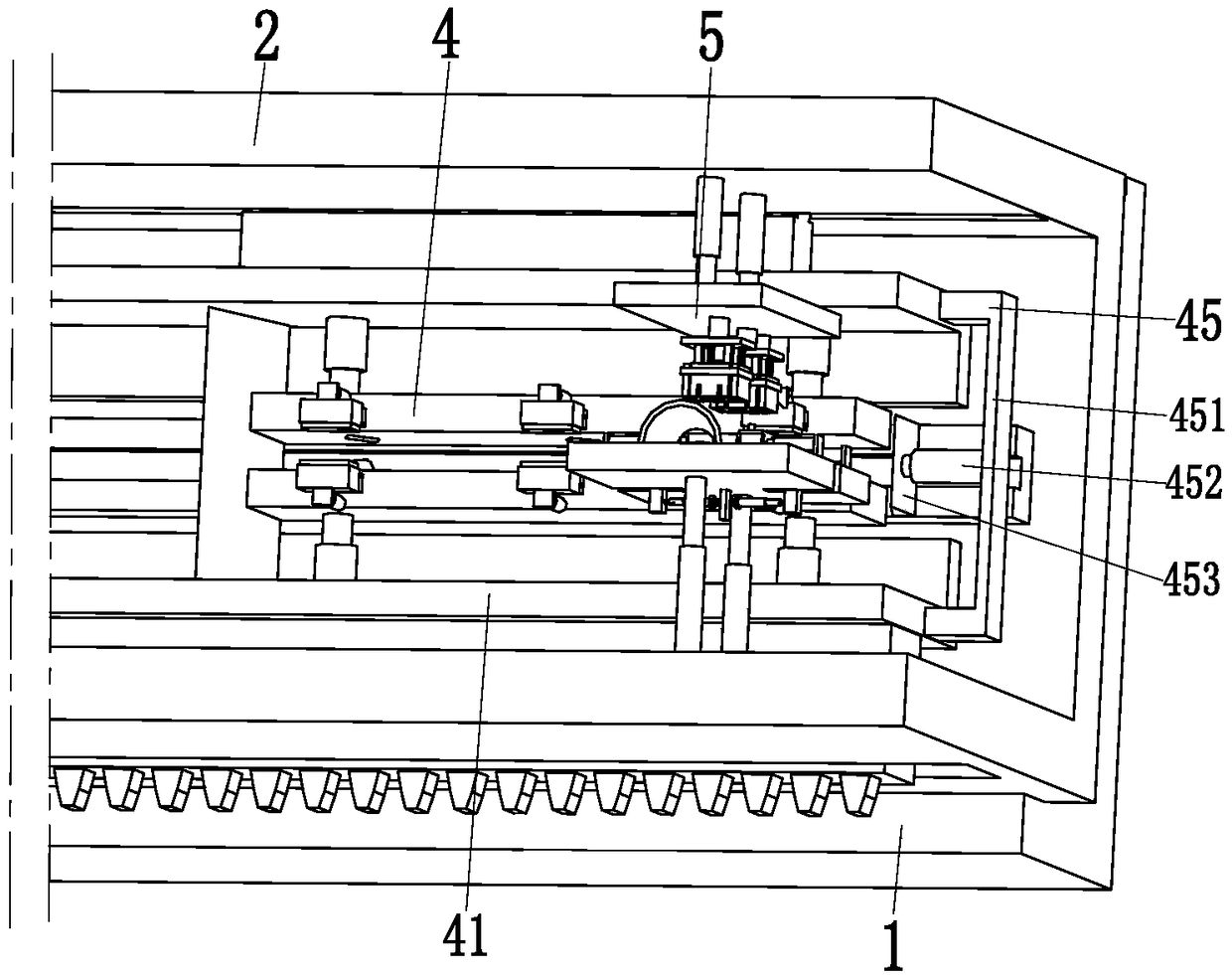

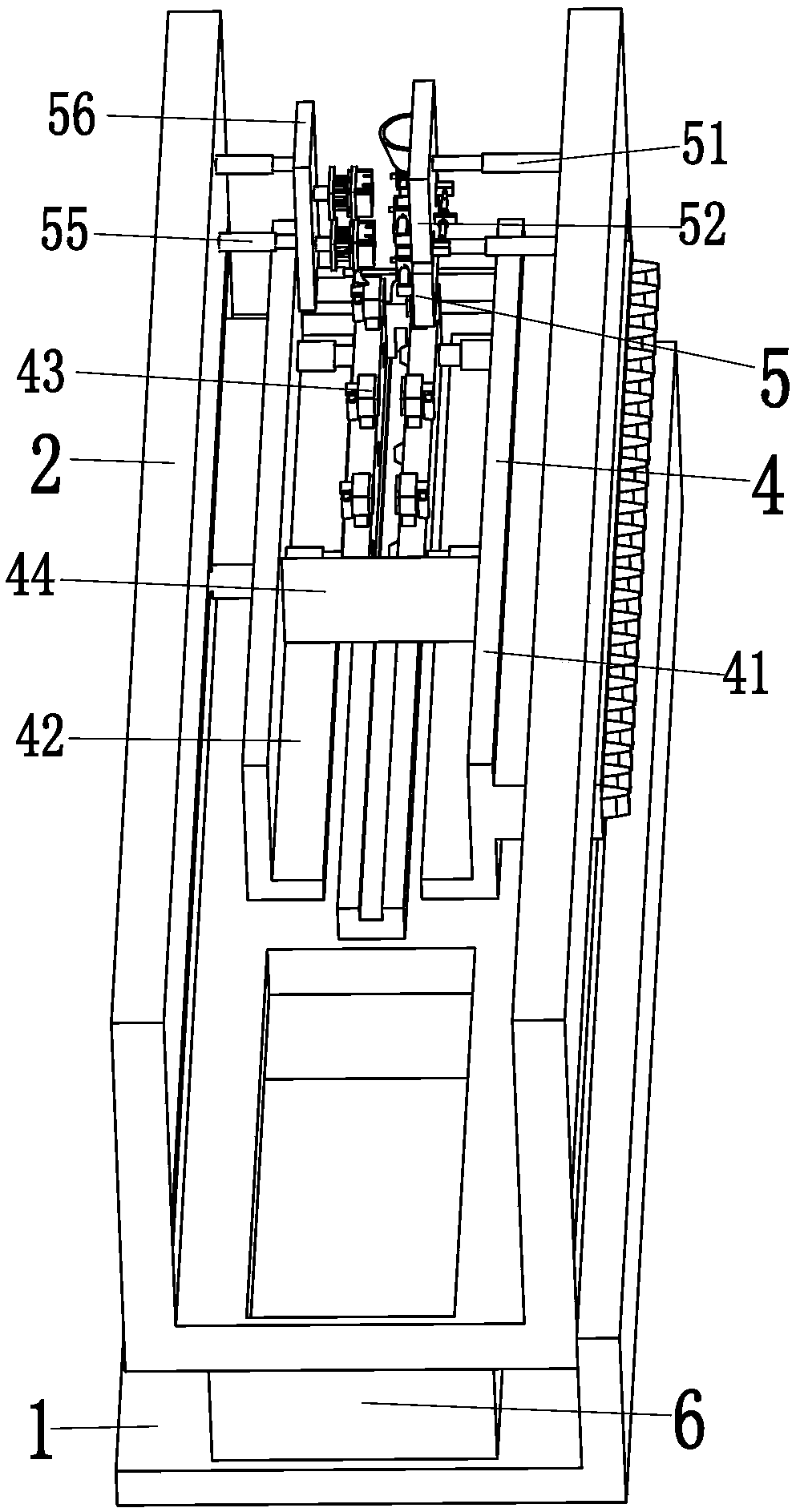

[0044] Such as Figure 1 to Figure 7 As shown, a power harness terminal fixed connection equipment includes a support base 1, a transmission frame 2, a transmission device 3, a fixing device 4, an extrusion device 5 and a material receiving b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com