Flitch dispensing device of box packing machine and the box packing machine

A cartoning machine and material sheet technology, which is applied in the direction of mechanical conveyors, packaging, conveyors, etc., can solve the problems of easy misalignment of material sheets, low work efficiency, fixed quantity distribution, etc. Fast, easy-to-operate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

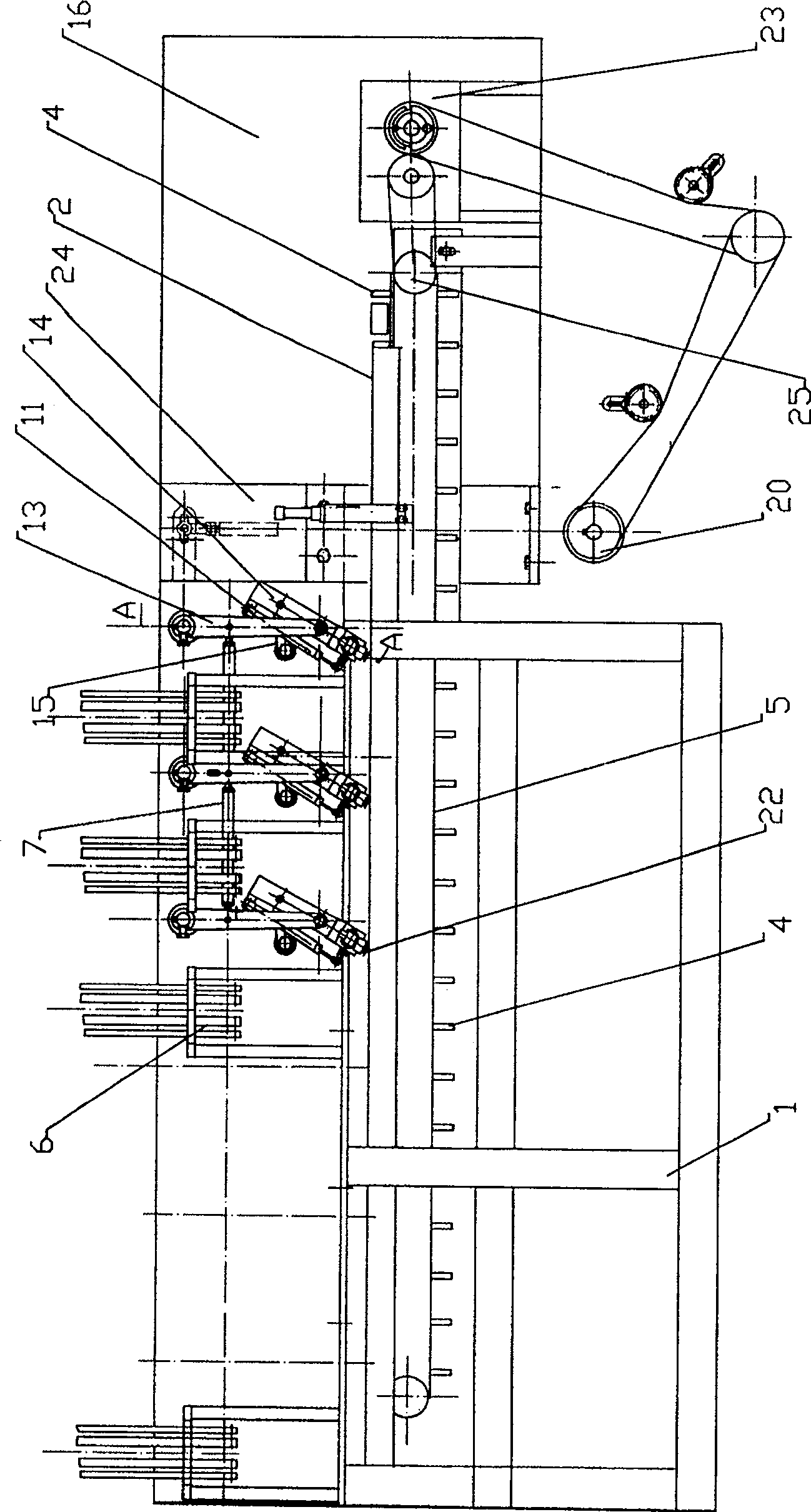

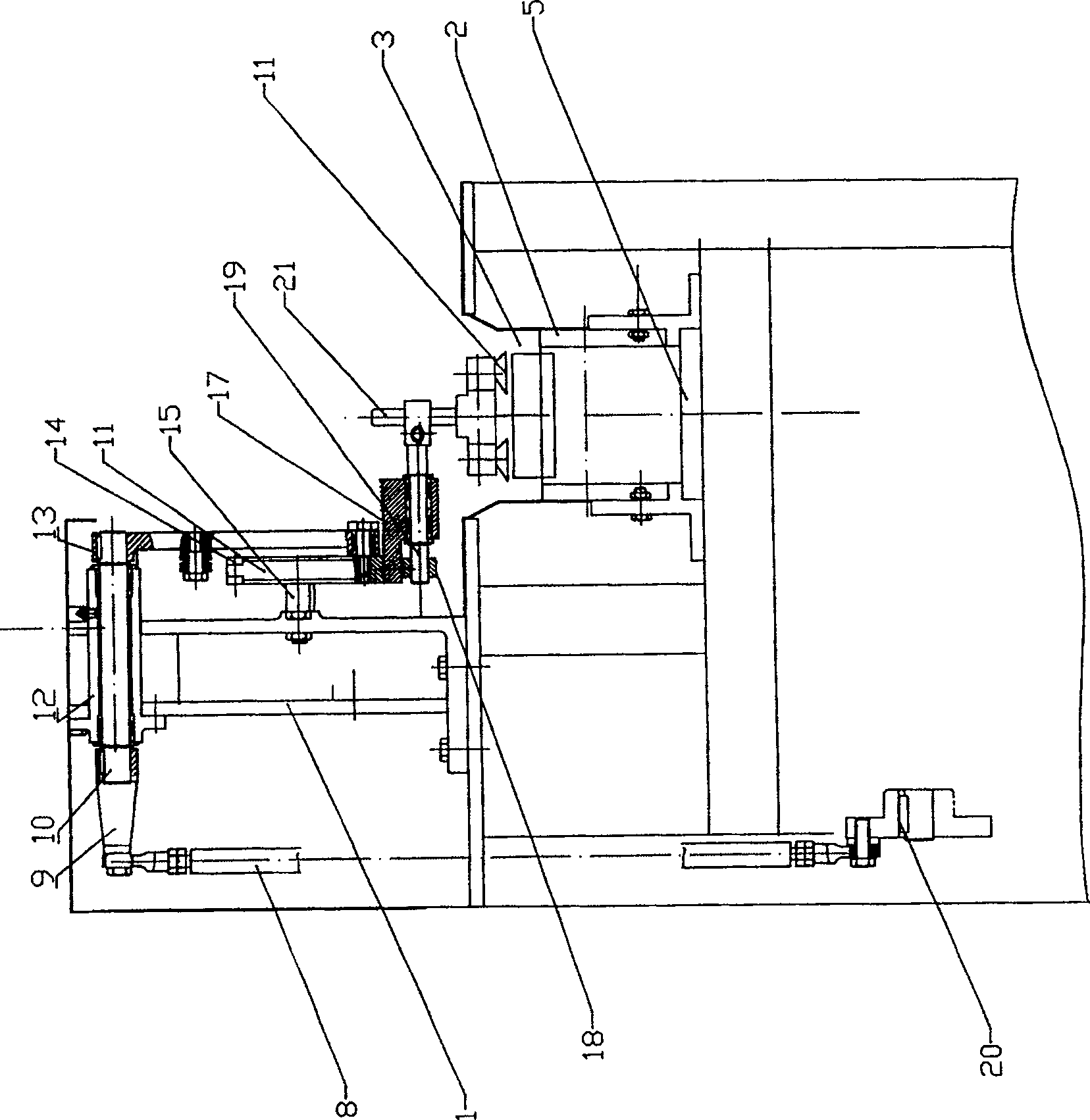

[0015] Such as figure 1 , figure 2 As shown, the conveyor belt 5 is located at the lower part of the frame 1, and the six swing mechanisms of the distribution device located on the upper part of the conveyor belt 5, as well as the six silos 6 and the cartoning device 16 are placed on the opposite left and right ends of the conveyor belt 5.架1上。 Shelf 1. The size of the collection chamber 3 formed by the partition 4 and the side guards 2 on both sides of the conveyor belt 5 is consistent with the size of the material plates to be packaged; six silos 6 with their outlets facing downwards are located in front of the conveyor belt 5 Above; and the six pendulum shafts 10 of the six pendulum swing mechanisms, each pendulum shaft 10 is coaxially fixed on the right side of each corresponding silo 6 through the swing seat 12 and the drive shaft 25 of the conveyor belt 5 Side frame 1; the end of the swing shaft 10 in front of the frame 1 is fixedly connected to the swing arm 13, the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com