Composite fur quilt and preparation method

A fur and quilt technology, applied in the field of bedding, can solve the problems of inability to protect against cold and warmth, loss of heat from sleeping bags, and damage to the human body, and achieve the effects of easy packaging and carrying, comfortable sleeping and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

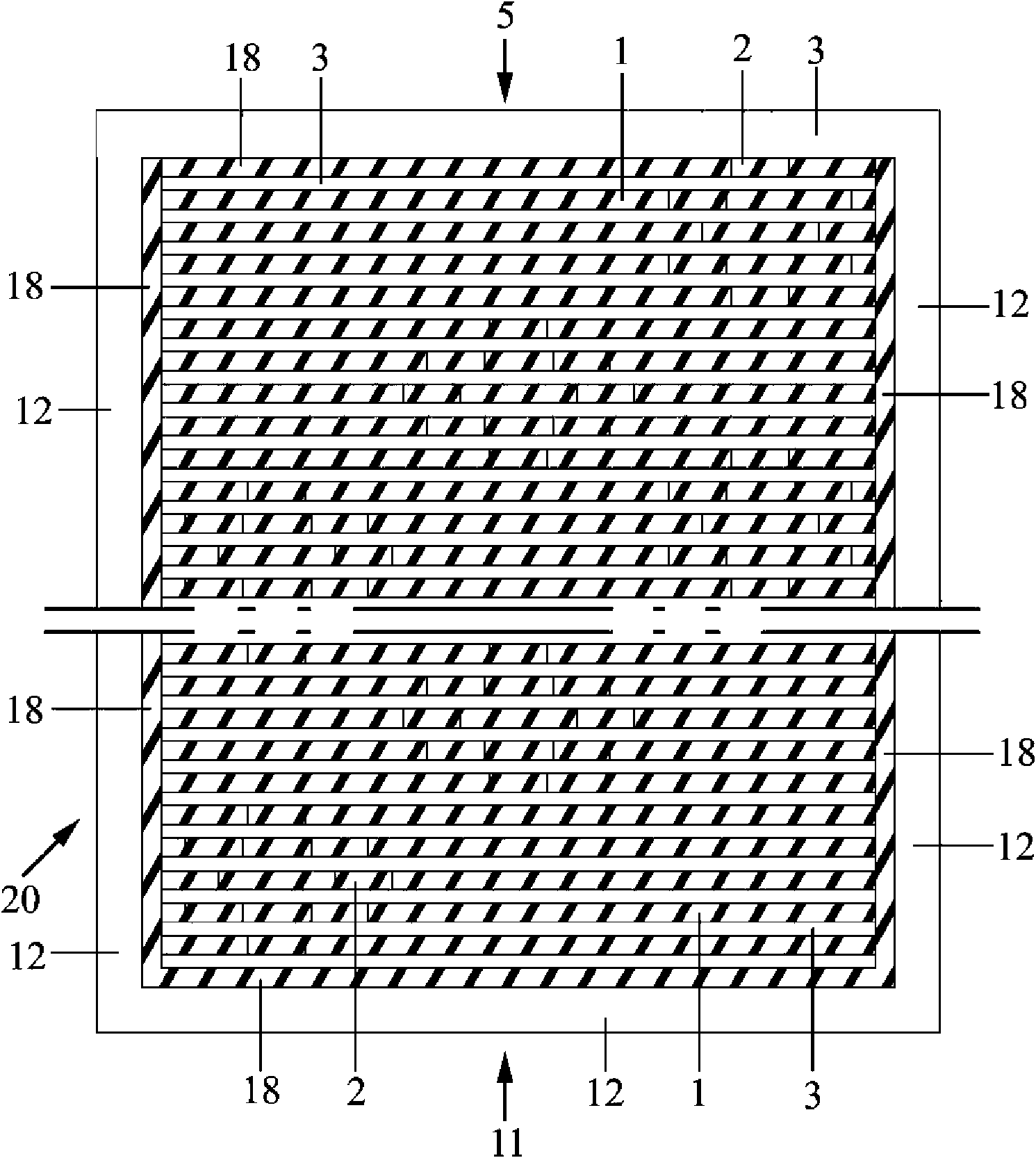

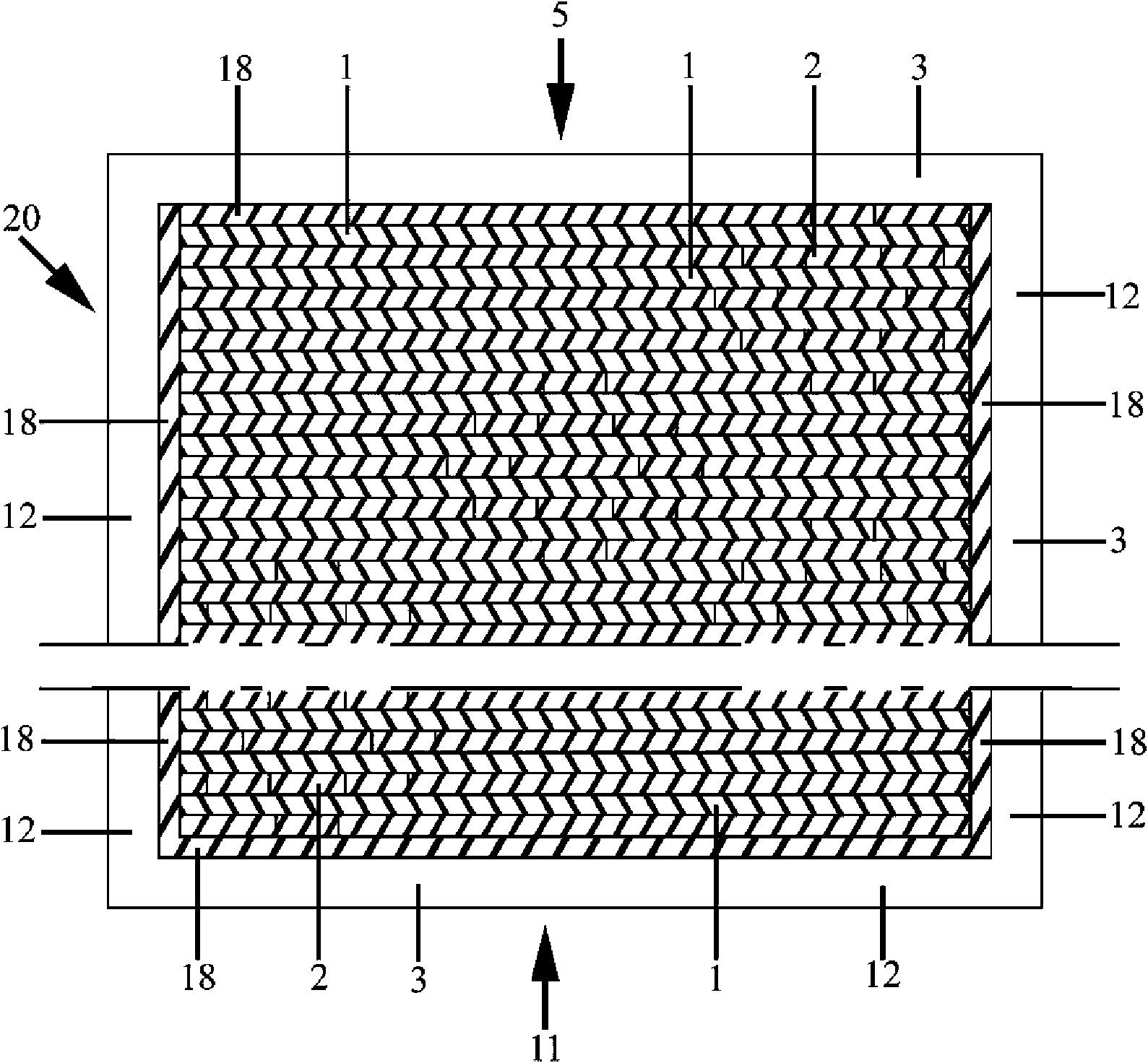

[0045] The quilt main body (20) as a whole is composed of the quilt surface (6) and the quilt lining (7), and the quilt surface (6) and the quilt lining (7) are stitched and connected along the periphery to form the quilt main body (20). ), form a hollow quilt cavity (19) between the quilt face (6) and the quilt lining (7) of sewing.

[0046] The quilt surface (6) is composed of strips of fur (18) and strips of textile fabrics (3) arranged at intervals and stitched and connected by sewing machine thread (16), or the strips of fur (18) are arranged side by side by sewing machine thread (16) Stitching connection constitutes, and the quilt surface (6) is thermally permeable again, and the wool face (14) of strip fur (18) is outwards, and the board face (15) of strip fur (18) is inward, and wool face (14) and strip The shaped textile fabric (3) constitutes a pattern of undulations.

[0047] The strip fur (18) is composed of a long strip of fur (1) and a short strip of fur (2) sti...

Embodiment 2

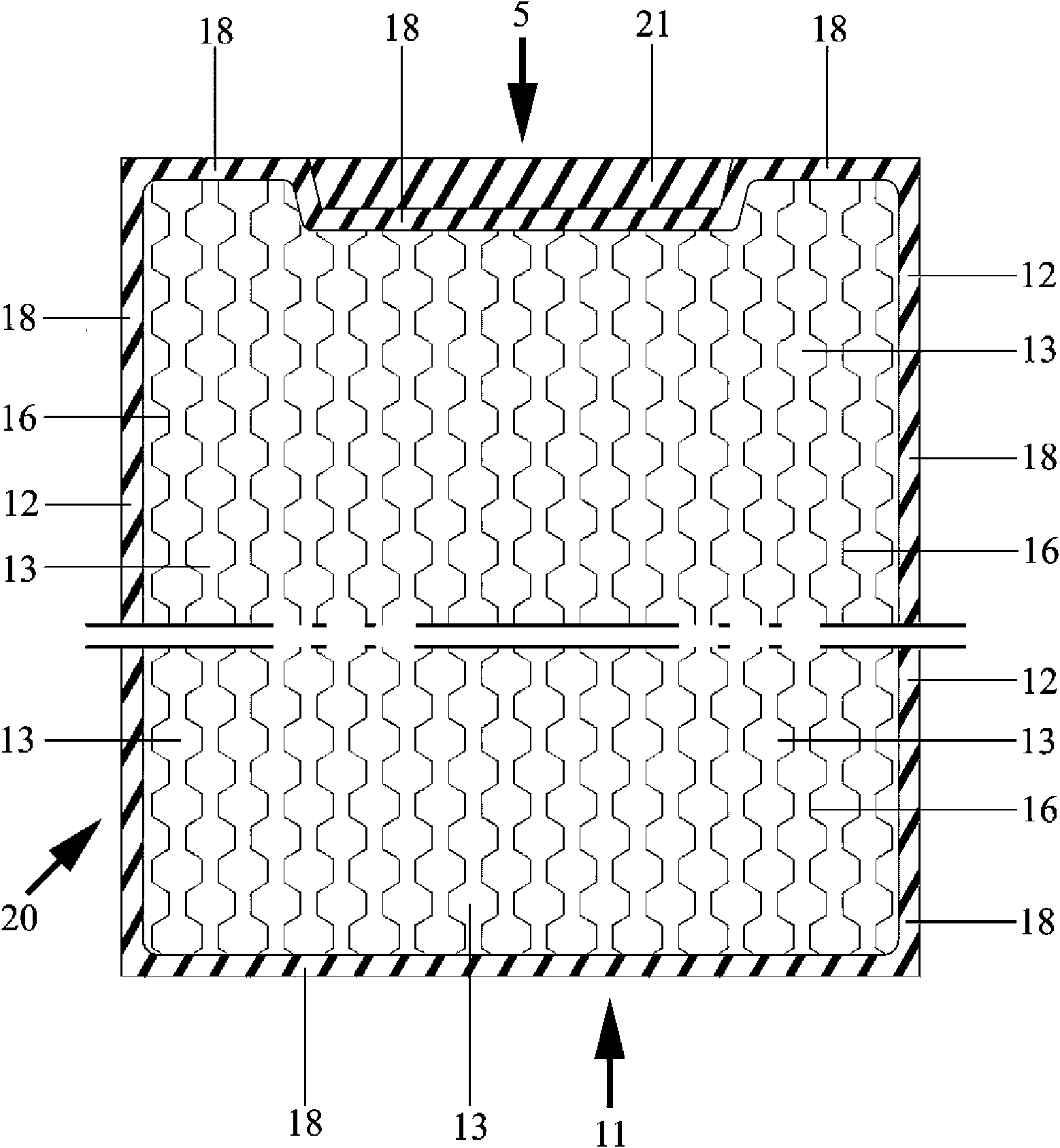

[0050] The lining (13) of the quilt lining (7) is to connect the cotton woven fabric (22) and the quilting fabric (17) by stacking and quilting, and the middle part of the quilt head (5) of the lining (13) is placed at the mouth (21) Be concave, connect the strip fur (18) by sewing machine thread (16) around the surroundings of the lining (13), the middle part of the quilt head (5) in the quilt (7) is provided with a quilt mouth (21), the quilt mouth (21) is an inverted trapezoid, and is connected by sewing the strip fur (18) of lining (13) and quilt head (5) by sewing machine thread (16) to form a whole quilt (7), quilt mouth (21), The quilt edge (12) and the quilt pin (11) reach wind resistance and keep warm, such as image 3 shown.

Embodiment 3

[0052] The quilt foot (11) is provided with a zipper (10) to form the filling port (9) of the quilt foot (11), and the composite filling sheet (8) is placed in the quilt cavity (19) through the filling port (9), adding a quilt cover body (20) operating temperature range.

[0053] The middle part of the composite filling sheet (8) is a textile filling (4), and the textile fabric (23) is wrapped and sewed to connect the textile filling (4) by a sewing machine thread (16) to form a composite filling sheet (8), and the composite filling sheet ( 8) coincide with the quilt cavity (19), such as Figure 4 , Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com