Gripper with heavy load and wide range

A gripper, wide-range technology, applied in the field of large-load, wide-range clamping devices, can solve the problems of complex structure and control, high cost, limited clamping range, etc., and achieve the effect of less degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

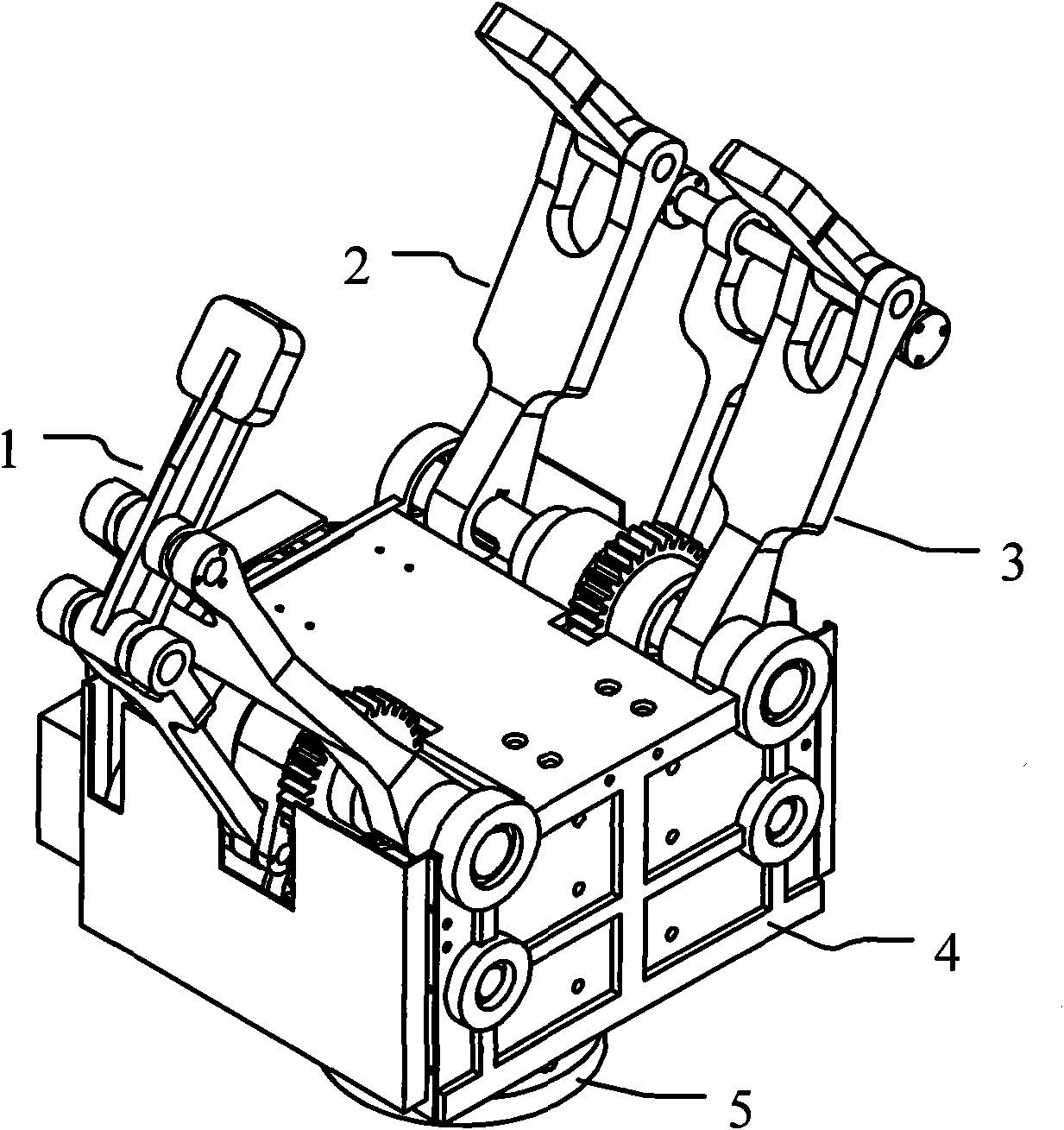

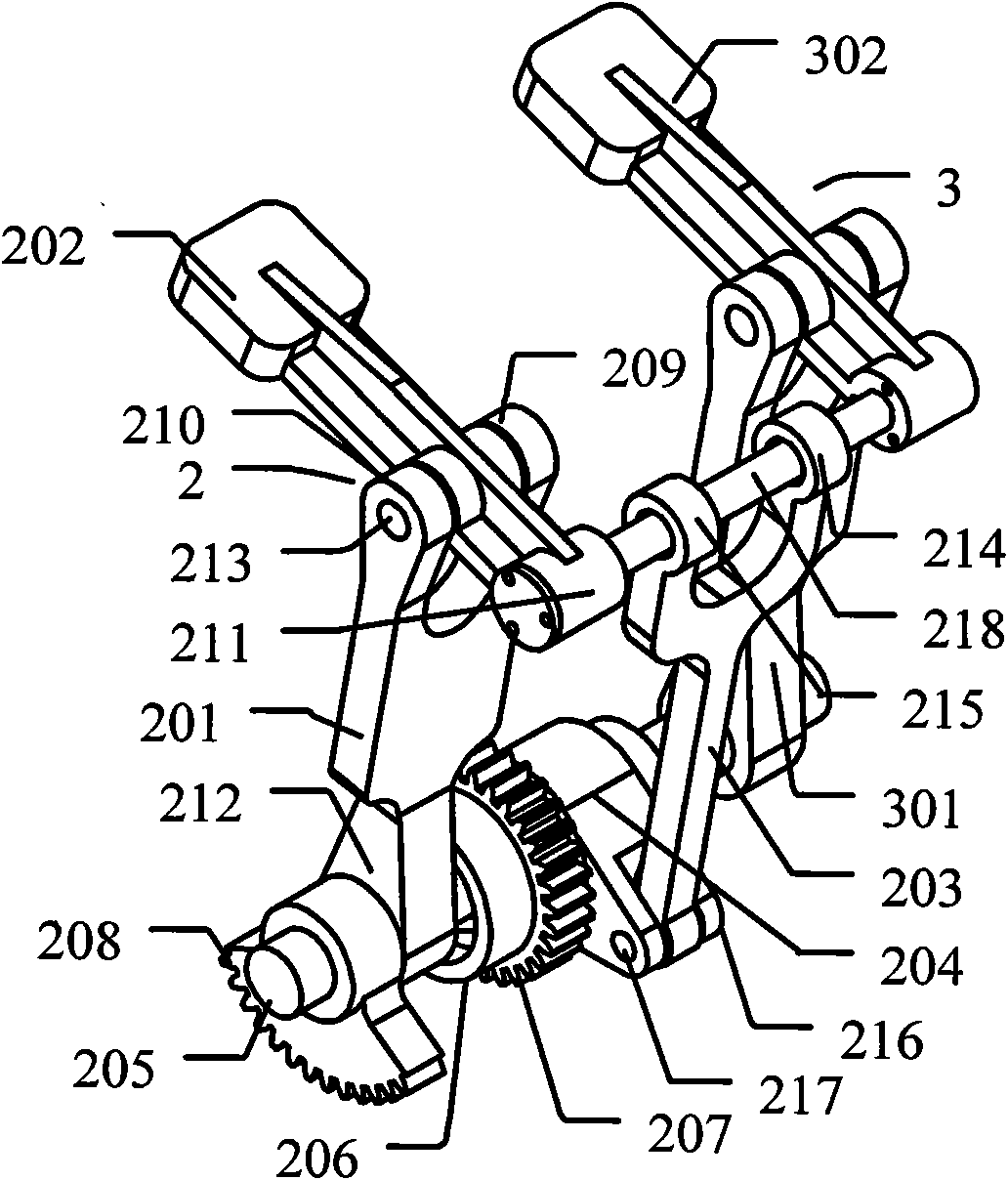

[0031] Such as figure 1 As shown, the present invention takes a clamper with three fingers A1, B2, C3, and each finger has two finger rods as an embodiment. Two fingers B2, C3 are arranged and one finger A1 is arranged on the other side. The number of the fingers is not limited to three, as long as the installation position of the fingers on one side is staggered from the installation position of the fingers on the other side, and no interference occurs during the movement of the fingers. The present invention also includes a transmission case 4 for arranging the driving device and installing the hands, and a connecting flange 5 that can be installed on the robot. The transmission case 4 can also be in other shapes that are convenient for installation and placement, and is not limited thereto.

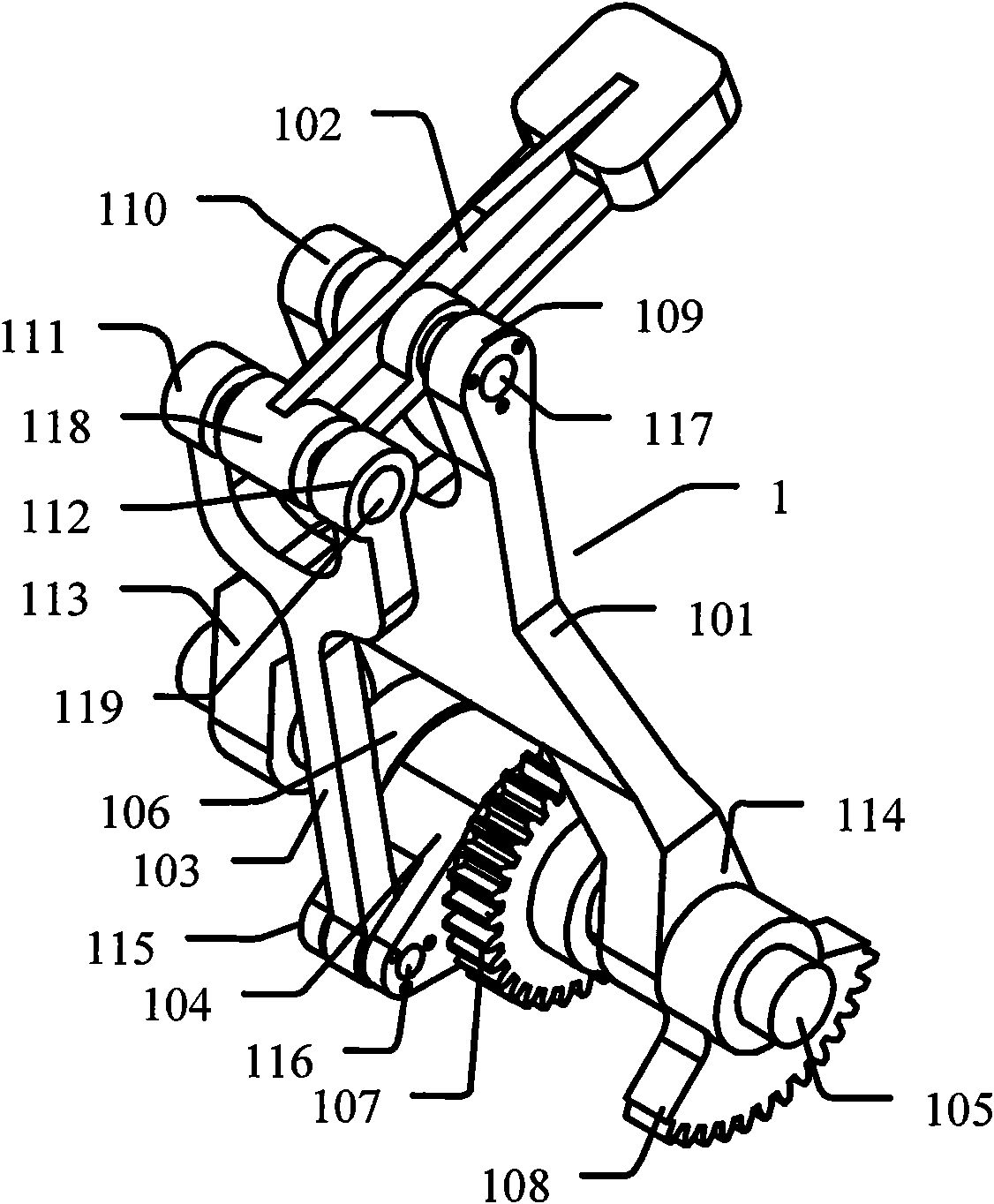

[0032] Such as figure 2 As shown, the finger A1 is composed of a first finger A101 and a second finger A102; wherein the first finger 101A and the sector gear 108 are connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com