Cleaning device

A technology for cleaning devices and support columns, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, and cleaning methods using liquids, etc. It can solve the problems of difficult cleaning of molded parts, limit the number of molded parts, and the volume occupied by stainless steel devices. Increased quantity, favorable mass production, clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

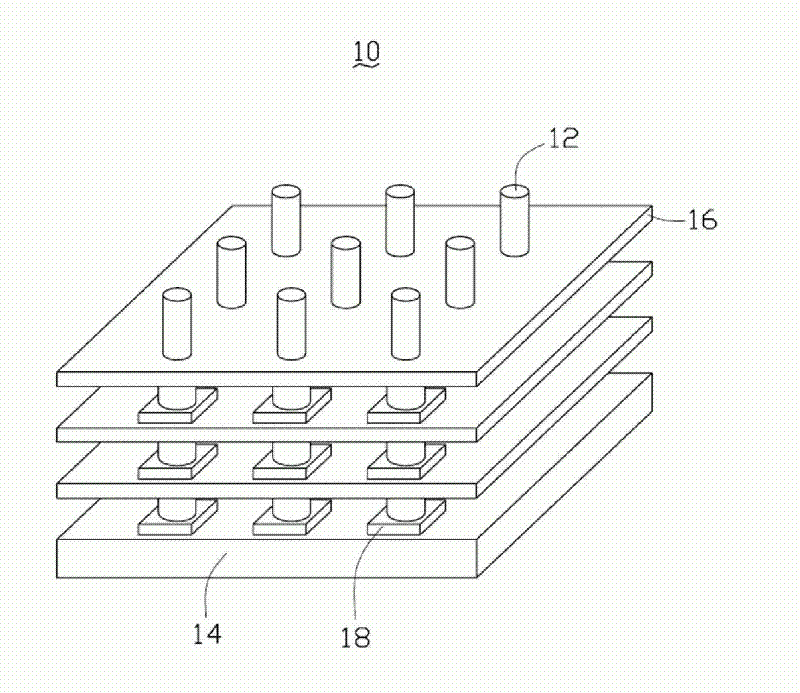

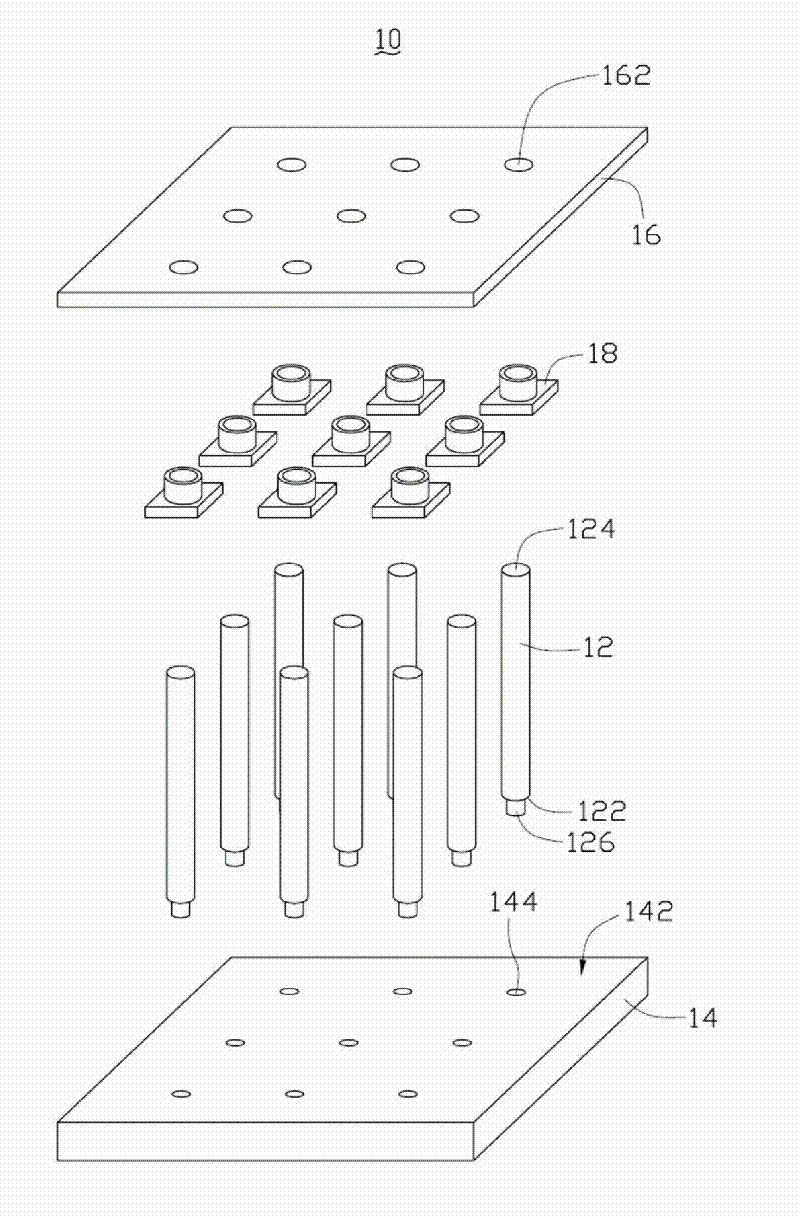

[0013] see figure 1 and figure 2 , The first embodiment of the present invention provides a cleaning device 10 which is used to clean a hollow molded part 18 . The cleaning device 10 includes a plurality of supporting columns 12 , a base 14 and three partitions 16 .

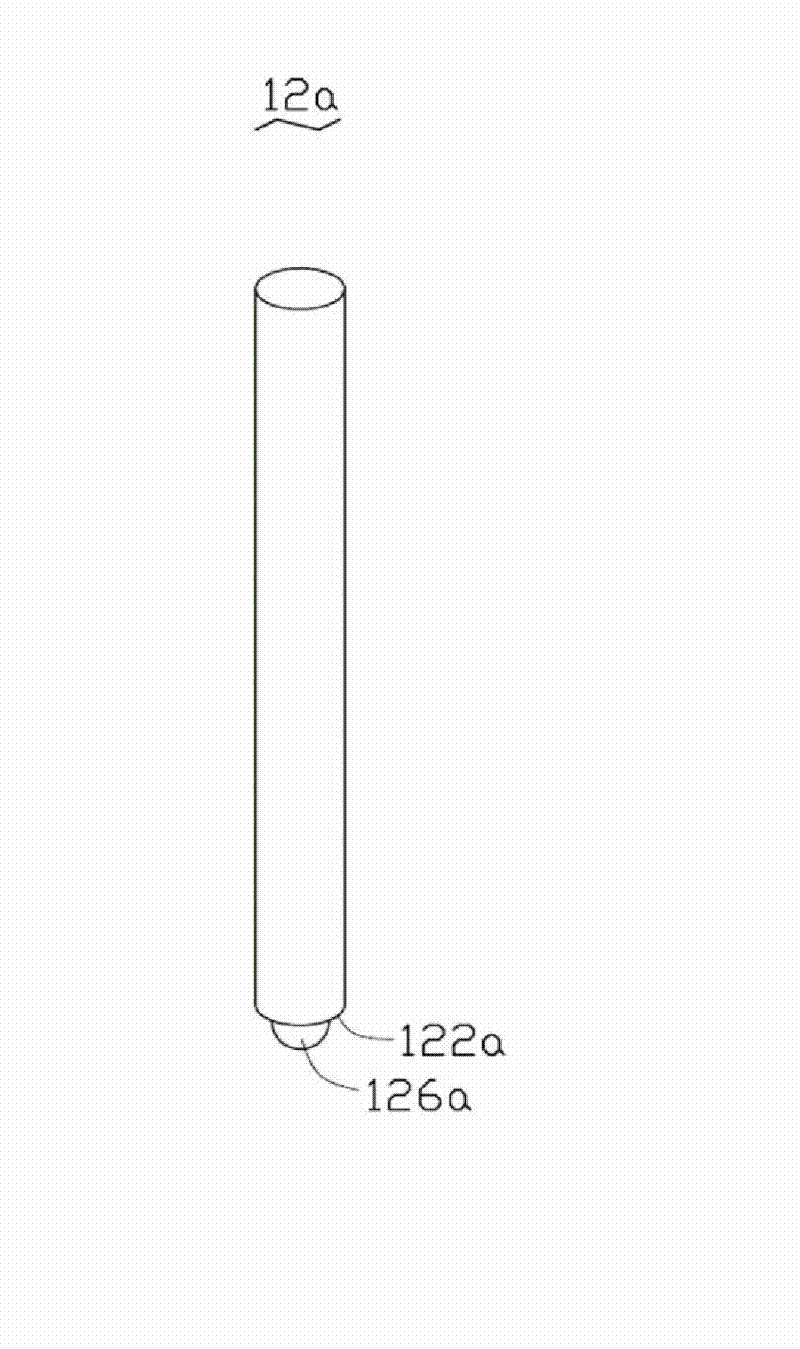

[0014] The support column 12 has a fixed end 122 and a free end 124 opposite to the fixed end 122 . The fixing end 122 is provided with at least one first fixing unit 126 . In this embodiment, the first fixing unit 126 is a cylinder whose central axis is parallel to the central axis of the support column 12 .

[0015] Of course, the first fixing unit 126 can also be a groove.

[0016] The base 14 has a first surface 142 . The first surface 142 is provided with a number of second fixing units 144 used in conjunction with the first fixing unit 126 to fix the fixing ends 122 of the plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com