Shelf lifter

A technology of lifts and shelves, which is applied in the field of shelf lifts, can solve problems such as slow lifting speed, low loading and unloading efficiency, and difficult loading and unloading, and achieve the effect of stable lifting of goods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

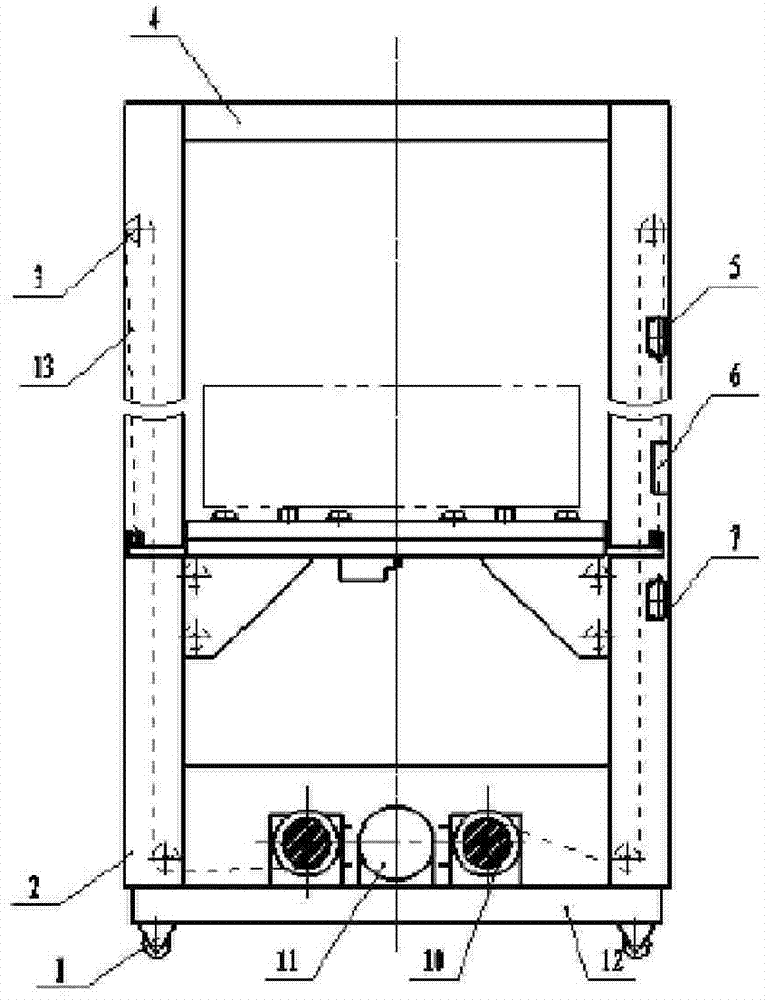

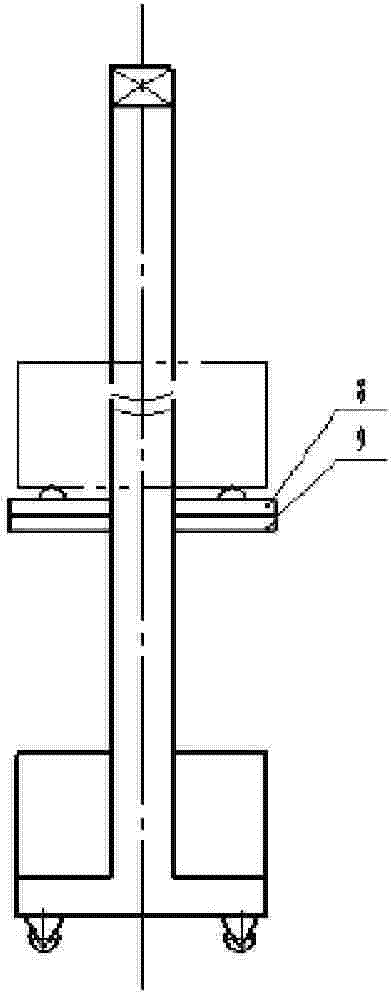

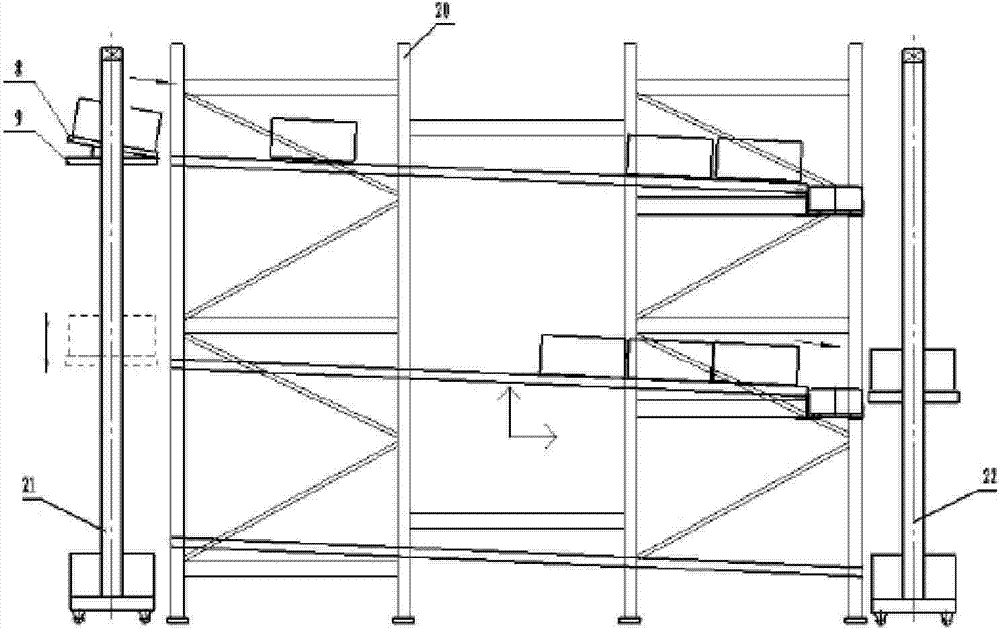

[0022] figure 1 , figure 2 with Figure 4-Figure 7 The shown shelf lifter includes a lifting device with a lifting platform 9 and a turning device arranged on the lifting platform. Described lifting device comprises chassis 12 and the vertical beam 2 that is symmetrically arranged on both sides of chassis and the crossbeam 4 that top connects two vertical beams, and lifting platform 9 is horizontally positioned between two vertical beams, and lifting platform is provided with on the lifting platform and two vertical beams. The guide rollers 14 corresponding to the track are rolled and matched, and a roller bracket 18 is fixedly installed on the lifting platform, and the guide rollers 14 are rotatably mounted on the roller bracket 18; wire rope pulley blocks 3 are respectively arranged on the two vertical beams, and one of the vertical beams also has a There is a lifting button 6, a flip button, a limit switch 5, and a travel switch 7. The chassis 12 is provided with a lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com