Omni-directional hydraulic breaker

A hydraulic crushing and all-round technology, applied in the direction of grain processing, etc., can solve the problems of feeder shutdown, reduced work efficiency, and excessive lumpiness of mineral materials, so as to ensure the safety of personnel and equipment and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

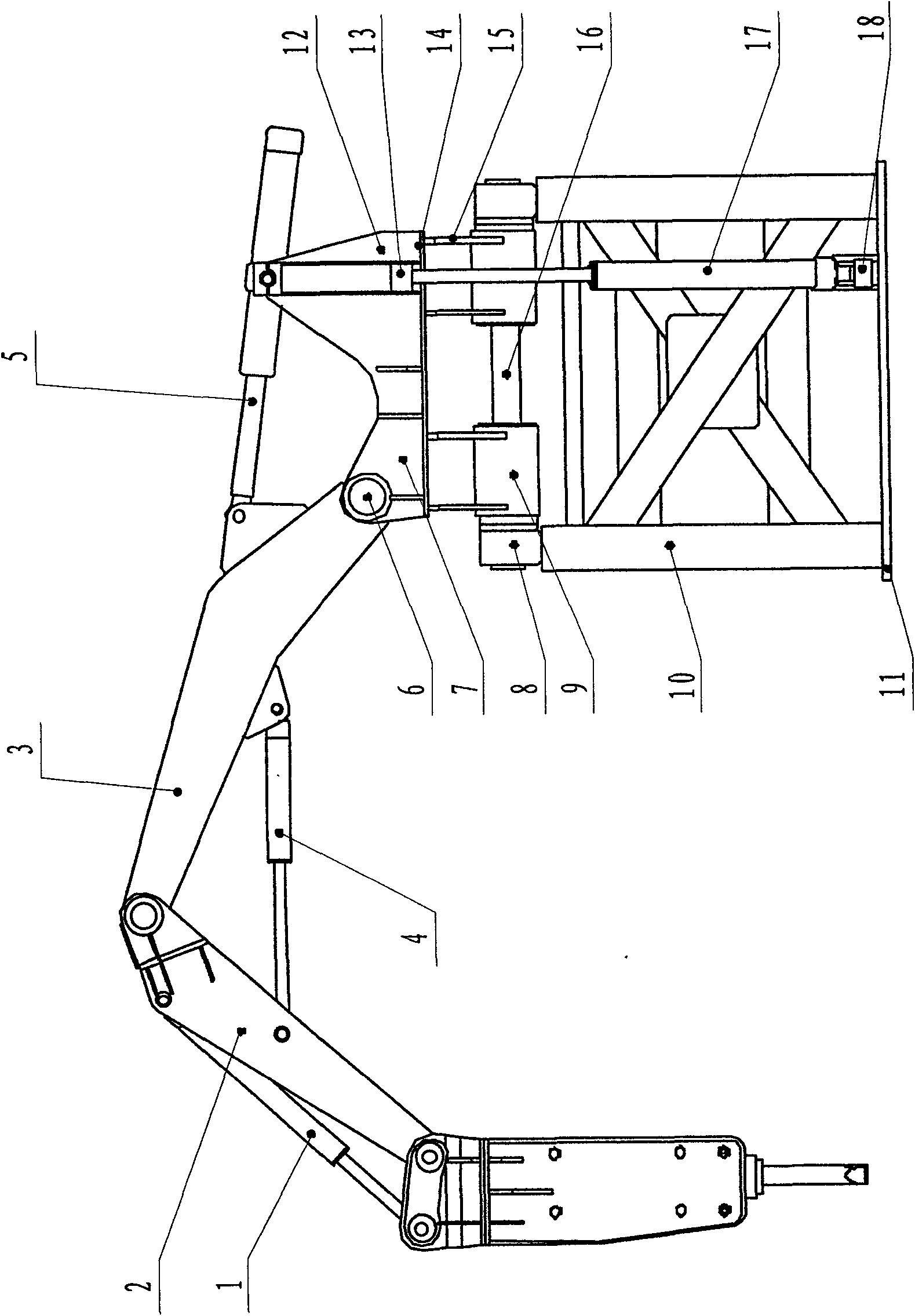

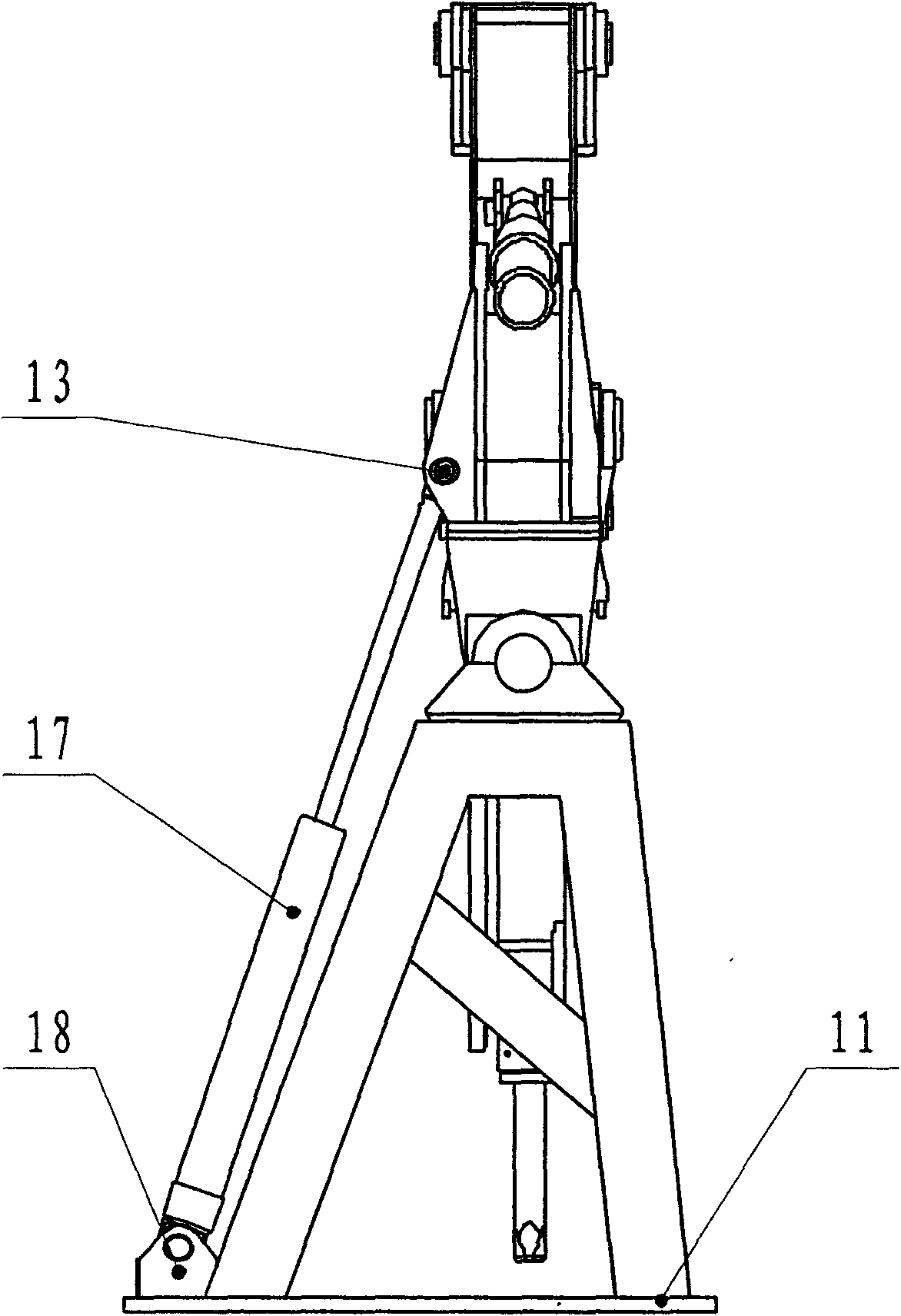

[0012] From figure 1 It can be seen that the all-round hydraulic breaker of the present invention includes a hydraulic breaker, a working device, a hydraulic device, an electrical device, a control device, and also includes a frame, a swing device, and a turning cylinder 17 .

[0013] From figure 1 It can be seen that the frame includes a mounting base plate 11 and front and rear mounting bases 8 connected thereto. Several bolt holes can be processed on the installation base plate 11, and are fastened with the foundation by high-strength bolts.

[0014] From figure 1 It can be seen that the swing device includes a rotary shaft 16 matched with the front and rear mounts 8, a shaft sleeve 9 matched with the rotary shaft 16, a side plate 15 for fixing the axial position of the shaft sleeve 9, a middle plate 14 connecting the side plate 15, a middle The front and back legs 7 and 12 are connected respectively at the front and rear ends of the top of the board 14 . Wherein, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com