Engagement chain

A meshing and sprocket technology, which is applied in the field of meshing chains, can solve the problems of reduced buckling strength of the meshing chain 500, inability to ensure the rigidity of the meshing chain 500, and shaking of the chain plate 550, so as to suppress shaking, realize light weight, and avoid overload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

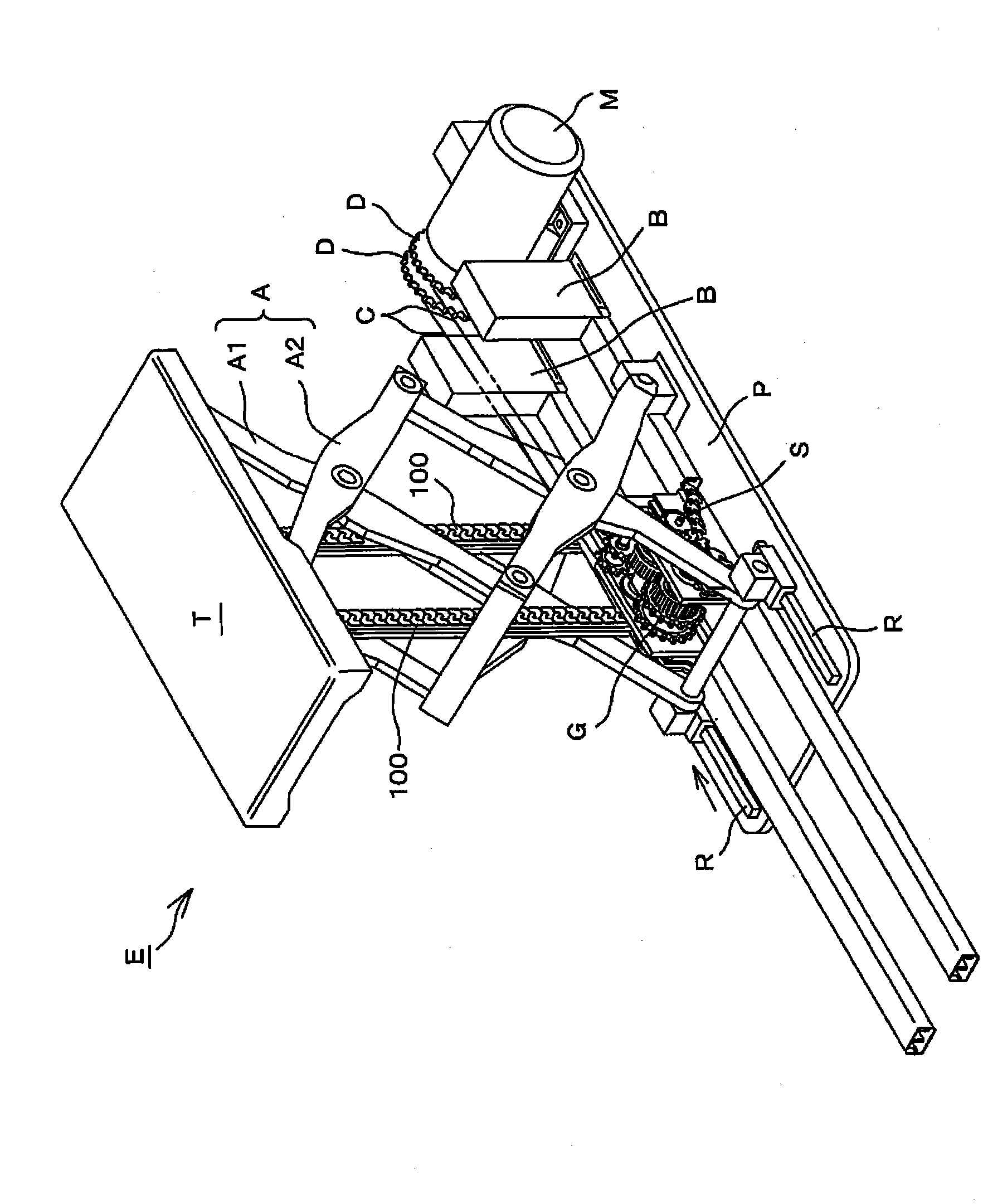

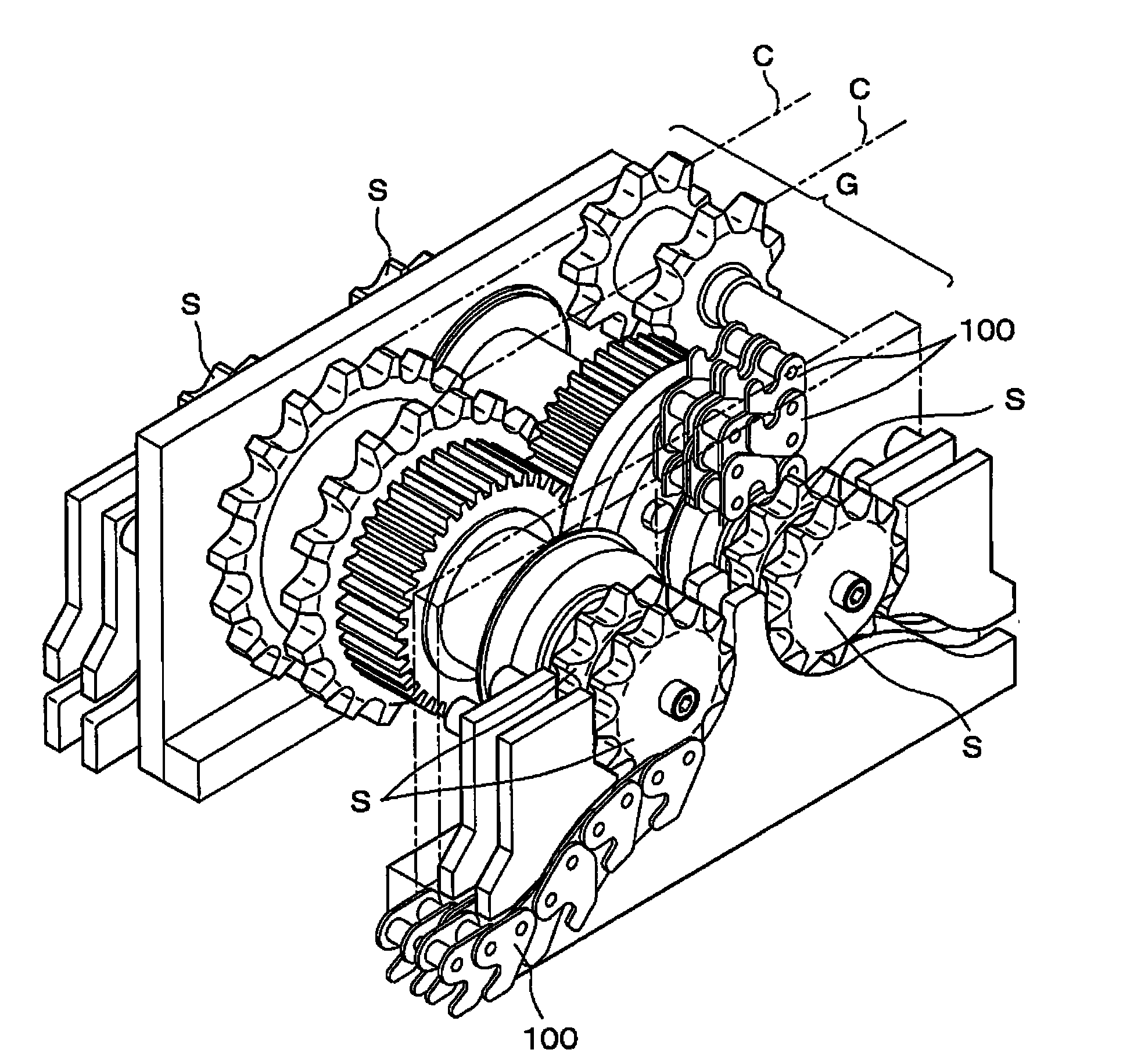

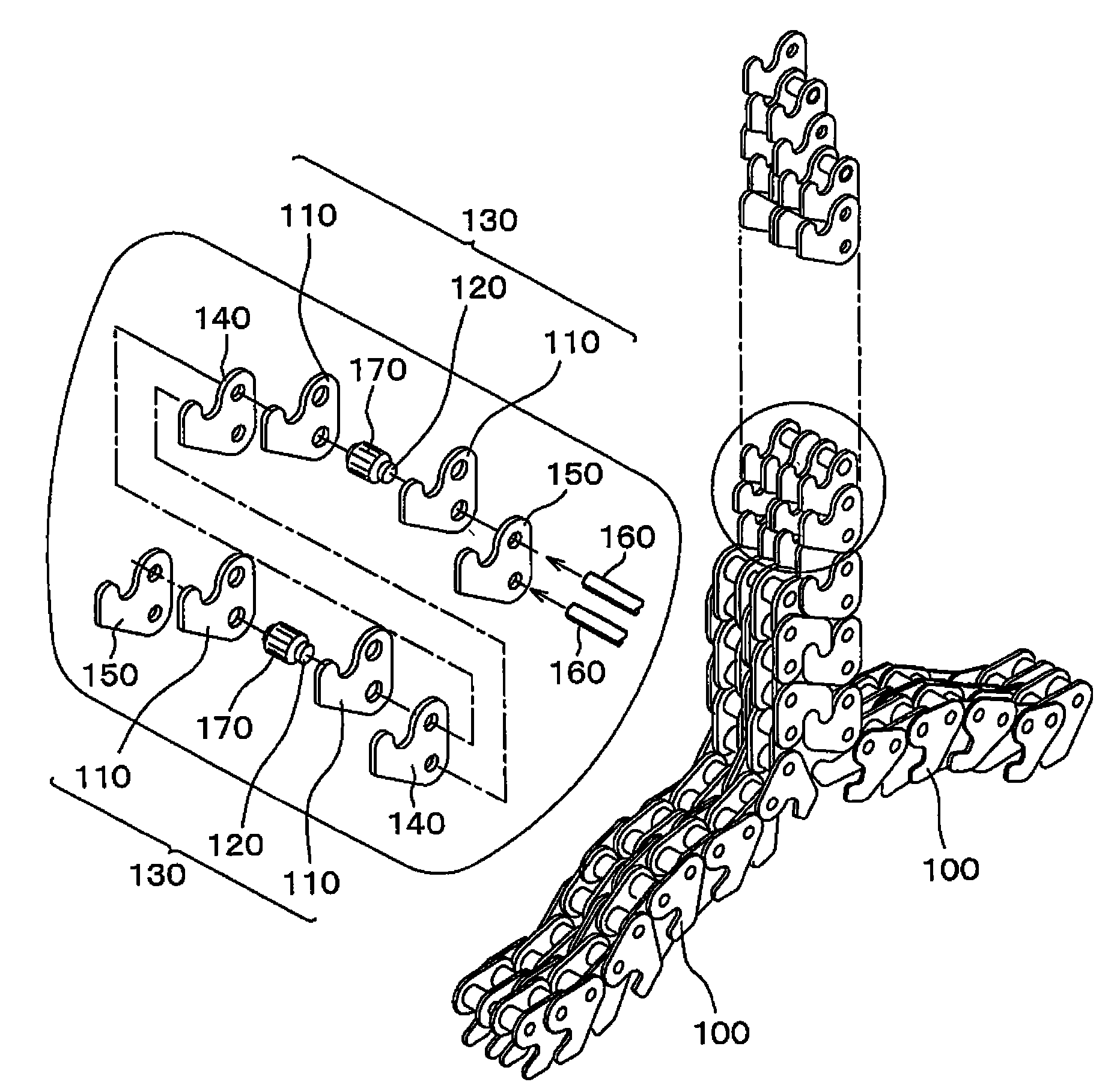

[0037] Hereinafter, the meshing chain 100 which is one Example of this invention is demonstrated based on drawing.

[0038] here, figure 1 It is a usage form diagram using the meshing chain as an embodiment of the present invention, figure 2 From figure 1 A perspective view of the state without the lifting table and the telescopic arm, image 3 is a partial enlarged view showing the meshing chain, Figure 4 is a partial sectional view showing the meshing chain, Figure 5 is a plan view showing the intermeshing external teeth, Figure 6 It is an explanatory diagram showing the state when the external gear pieces start meshing with each other, Figure 7 is an explanatory diagram showing a state in which the external gear pieces mesh with each other, Figure 8 It is an explanatory diagram showing a state in which the external gear pieces mesh with each other.

[0039] First, if figure 1 As shown, the meshing chain 100 as an embodiment of the present invention is assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com