Ratchet-type tensioner

A tensioner and ratchet-type technology, applied in the directions of machines/engines, belts/chains/gears, valve details, etc., can solve the problem of damage to the meshing teeth 536 and the rack 538, and the inability to completely and quickly release the meshing teeth 536 and the teeth Article 538. Problems that cannot be completely prevented, etc., to achieve the effect of simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

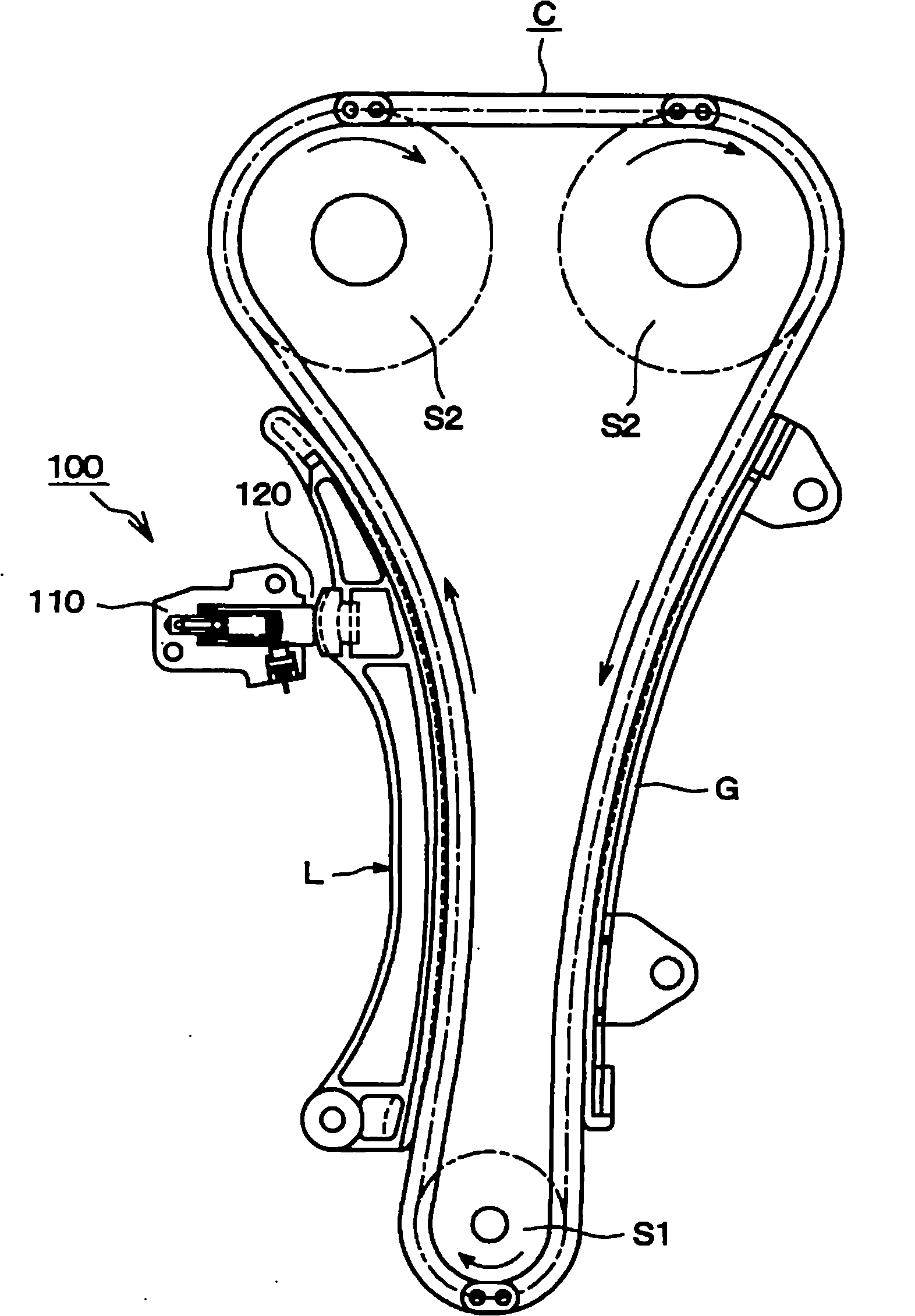

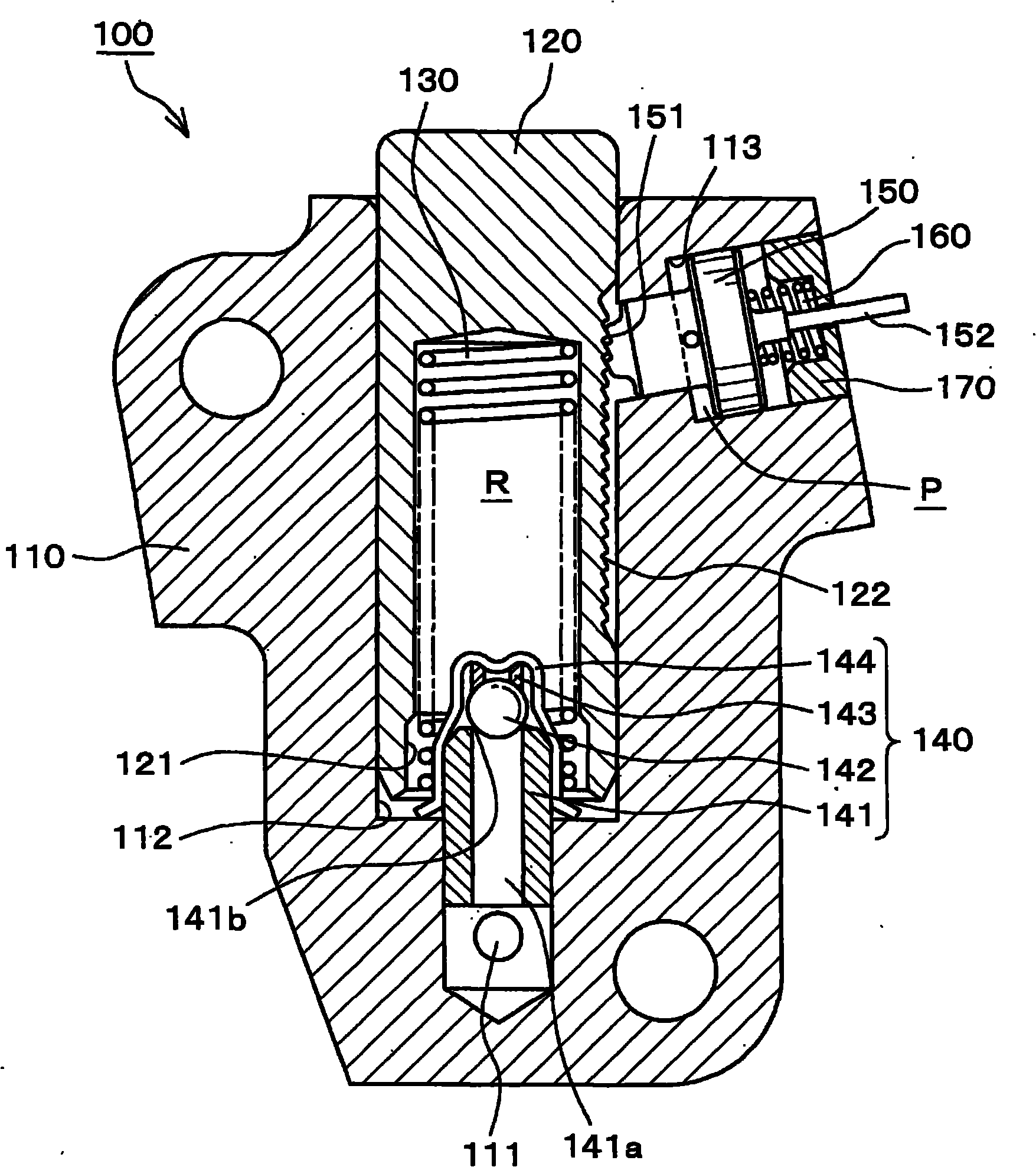

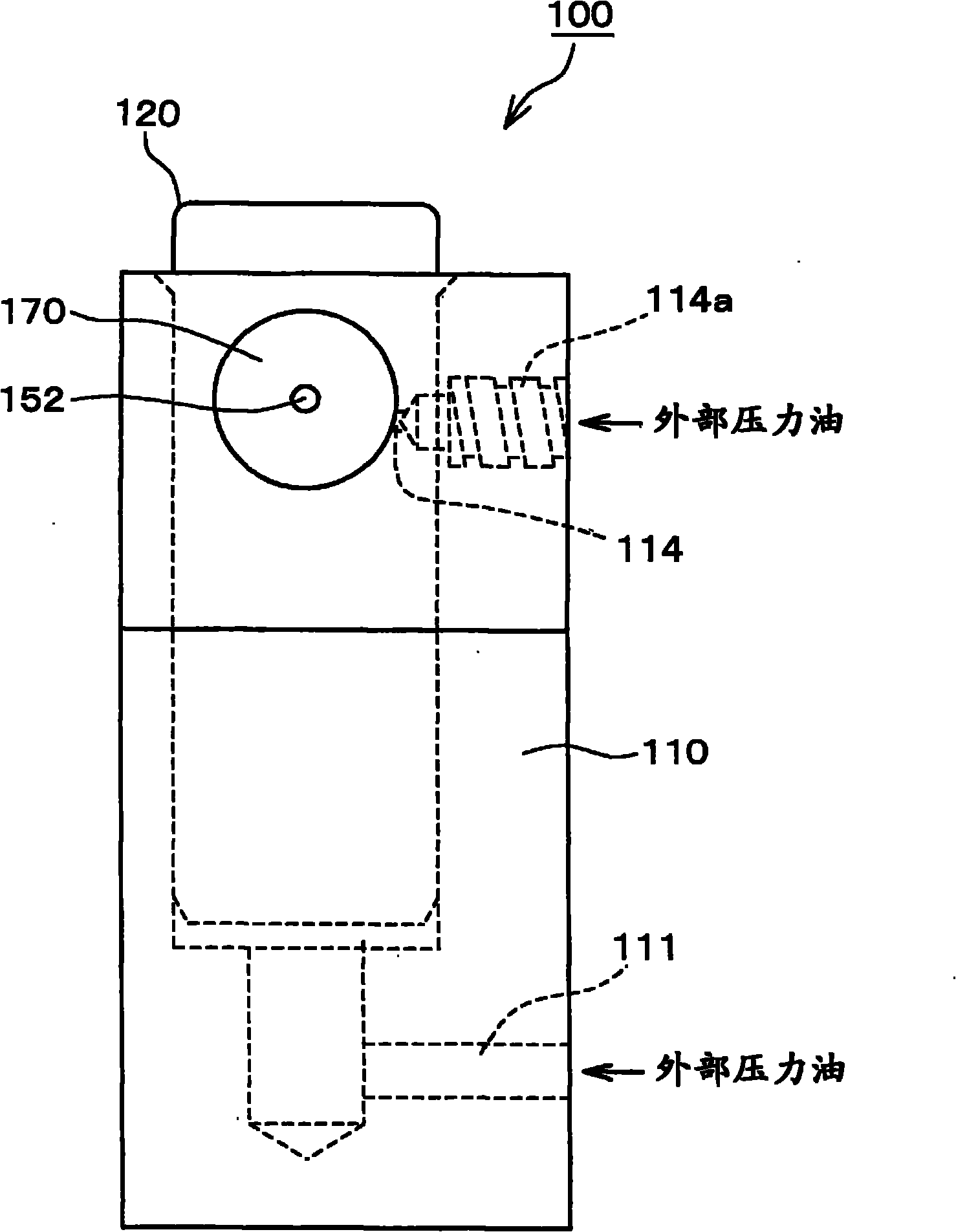

[0033] Refer to the following Figure 1 to Figure 6 A ratchet type tensioner 100 which is an embodiment of the present invention will be described.

[0034] here, figure 1 It is a use state diagram of the ratchet tensioner 100 according to the first embodiment of the present invention. figure 2 for figure 1 An enlarged cross-sectional view of ratchet tensioner 100 is shown, image 3 its side view. Figure 4 It is a cross-sectional view showing the meshing state of the rack teeth of the plunger and the ratchet pawl of the piston with ratchet. Figure 5 It is a cross-sectional view showing the meshing release state of the rack teeth of the plunger and the ratchet pawl of the piston with ratchet.

[0035] First, if figure 1 As shown, the ratchet type tensioner 100 according to the first embodiment of the present invention is of the timing chain C wound between the driving side sprocket S1 rotated by the crankshaft of the engine and the driven side sprocket S2 fixed to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com