Method for measuring hydrogen pressure in solid steel and device

A hydrogen pressure, solid-state technology, applied in the field of solid electrolytes and chemical sensors, can solve problems such as expensive, inconvenient to use, and difficult to store

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

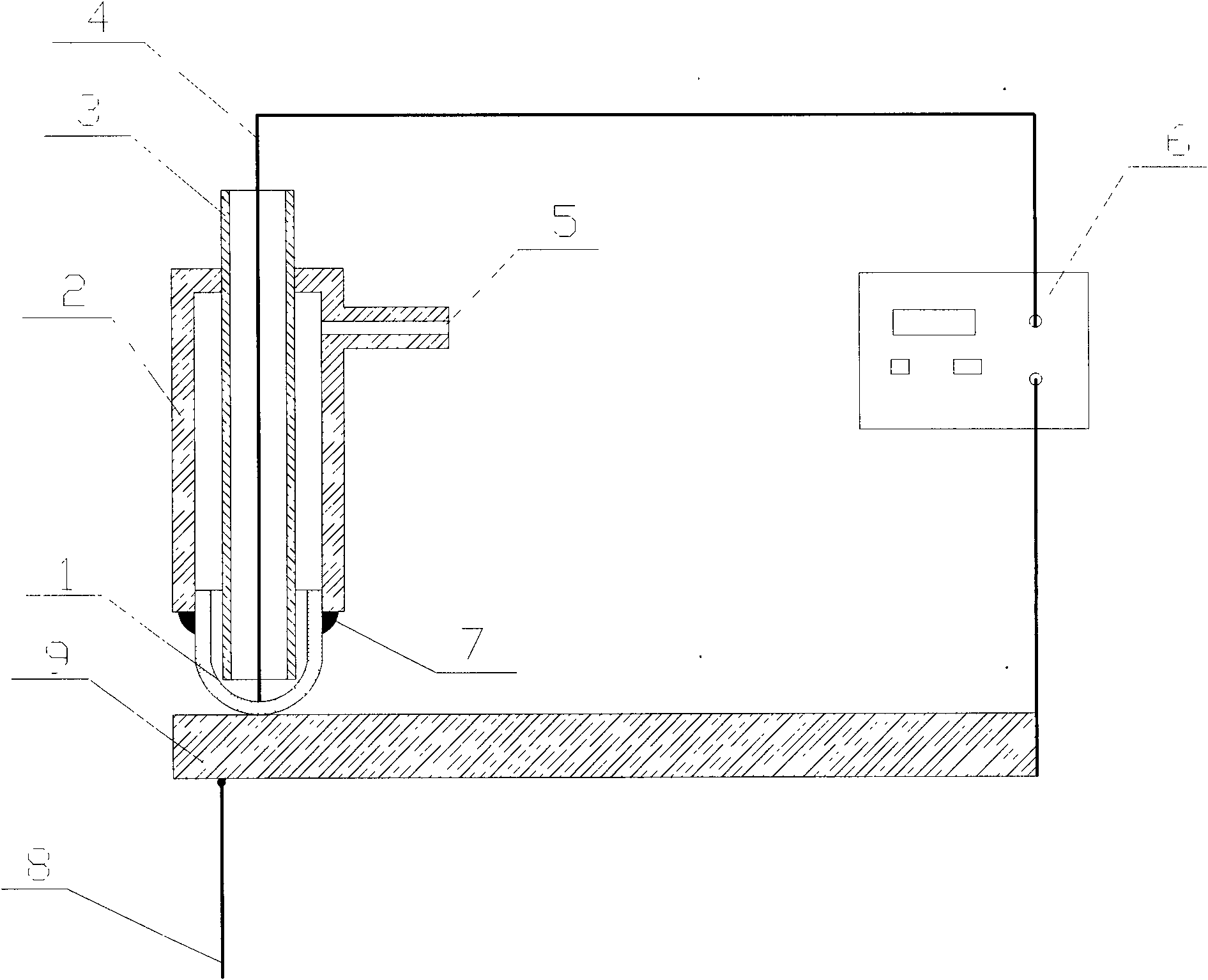

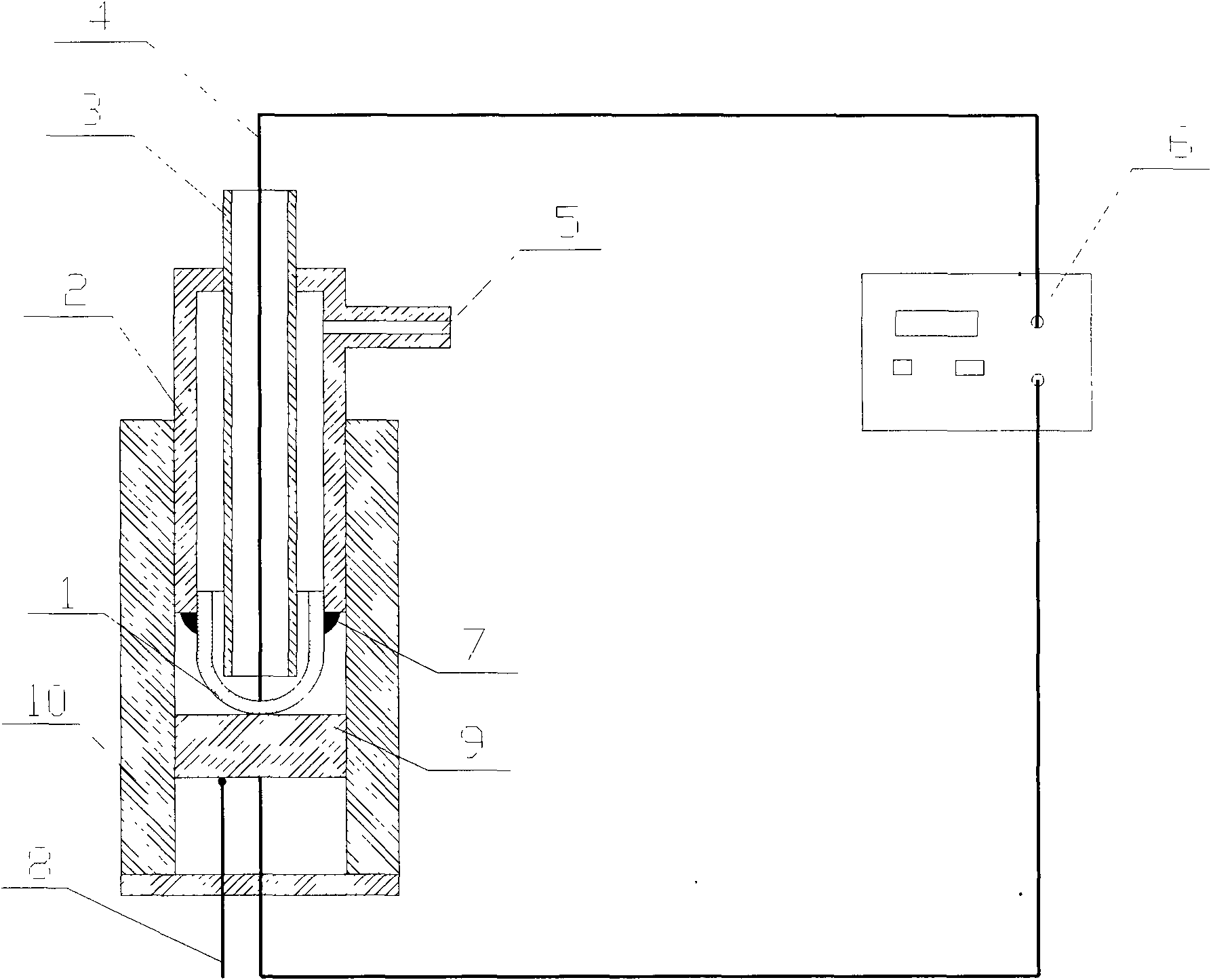

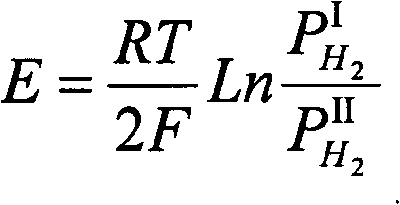

[0067] The device of the present invention is composed of a ceramic solid electrolyte tube 1, a corundum tube 2, an air intake tube 3, an electrode lead 4, an exhaust tube 5 and a high-resistance digital voltmeter 6, and one end of the corundum tube 2 is connected to the open end of the ceramic solid electrolyte tube 1, That is, the corundum tube 2 and the ceramic solid electrolyte tube 1 are socketed and glued together. Adhesive 7 is selected from commercially available epoxy resin adhesives. The intake pipe 3 passes through the closed end of the corundum tube 2, extends into the corundum tube 2 and is close to the inner wall of the bottom of the ceramic solid electrolyte tube 1, and there is a gap between the outer wall and end surface of the intake tube 3 and the bottom inner wall of the ceramic solid electrolyte tube 1, and the gap can Pass standard hydrogen. An exhaust pipe 5 is provided on the side wall of the corundum pipe 2 . One end of the electrode lead wire 4 exte...

Embodiment 2

[0096]The device of the present invention is composed of a ceramic solid electrolyte tube 1, a corundum tube 2, an air intake tube 3, an electrode lead 4, an exhaust tube 5 and a high-resistance digital voltmeter 6, and one end of the corundum tube 2 is connected to the open end of the ceramic solid electrolyte tube 1, That is, the corundum tube 2 and the ceramic solid electrolyte tube 1 are socketed and glued together. Adhesive 7 is selected from commercially available acrylic resin adhesive. The intake pipe 3 passes through the closed end of the corundum tube 2, extends into the corundum tube 2 and is close to the inner wall of the bottom of the ceramic solid electrolyte tube 1, and there is a gap between the outer wall and end surface of the intake tube 3 and the bottom inner wall of the ceramic solid electrolyte tube 1, and the gap can Pass standard hydrogen. An exhaust pipe 5 is provided on the side wall of the corundum pipe 2 . One end of the electrode lead wire 4 exte...

Embodiment 3

[0125] The device of the present invention is composed of a ceramic solid electrolyte tube 1, a corundum tube 2, an air intake tube 3, an electrode lead 4, an exhaust tube 5 and a high-resistance digital voltmeter 6, and one end of the corundum tube 2 is connected to the open end of the ceramic solid electrolyte tube 1, That is, the corundum tube 2 and the ceramic solid electrolyte tube 1 are socketed and glued together. Adhesive 7 is selected from commercially available instant dry adhesive (502 glue). The intake pipe 3 passes through the closed end of the corundum tube 2, extends into the corundum tube 2 and is close to the inner wall of the bottom of the ceramic solid electrolyte tube 1, and there is a gap between the outer wall and end surface of the intake tube 3 and the bottom inner wall of the ceramic solid electrolyte tube 1, and the gap can Pass standard hydrogen. An exhaust pipe 5 is provided on the side wall of the corundum pipe 2 . One end of the electrode lead w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

| Tube length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com