Power hub

A wheel hub and yoke technology, applied in the field of power generation hubs, can solve problems such as easy deformation, adjustment, and hindering the positioning of yoke claws, and achieve the effects of high structural strength, flexible structural changes, and easy winding work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

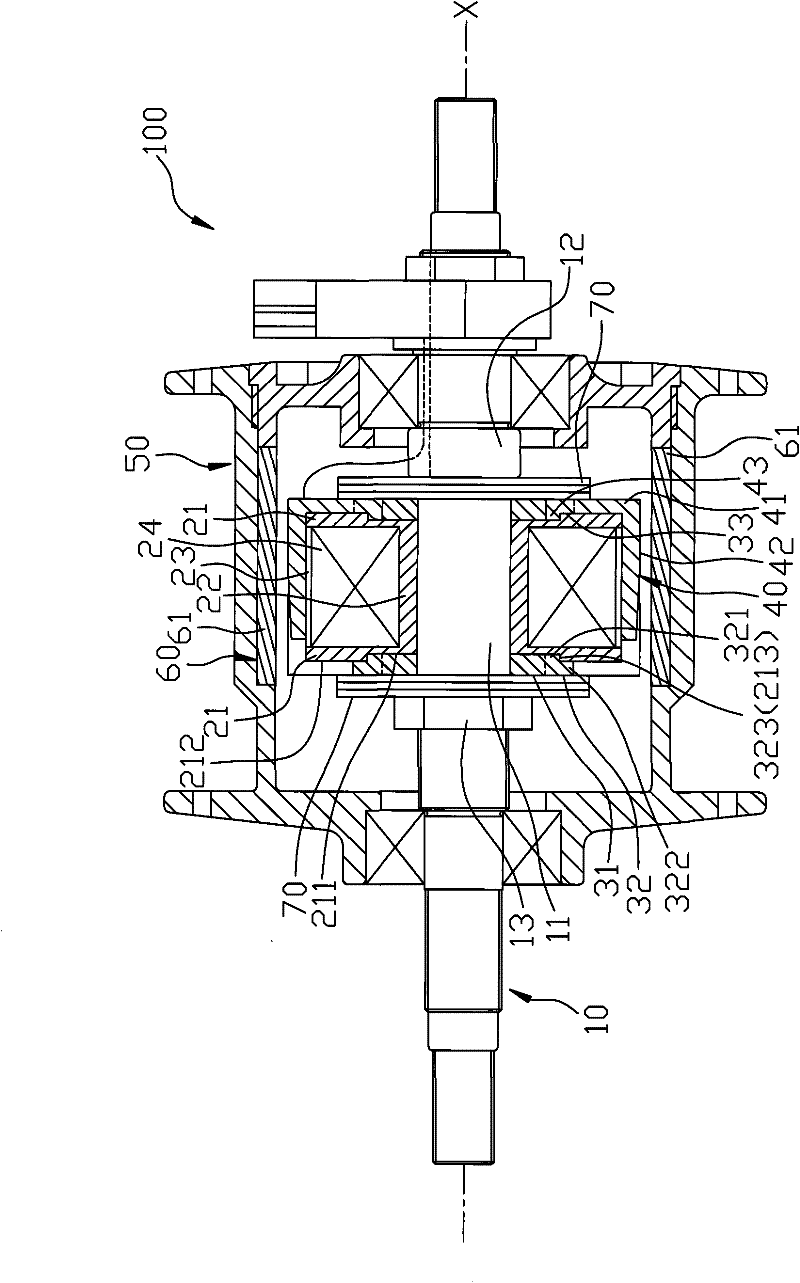

[0011] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0012] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same reference numerals.

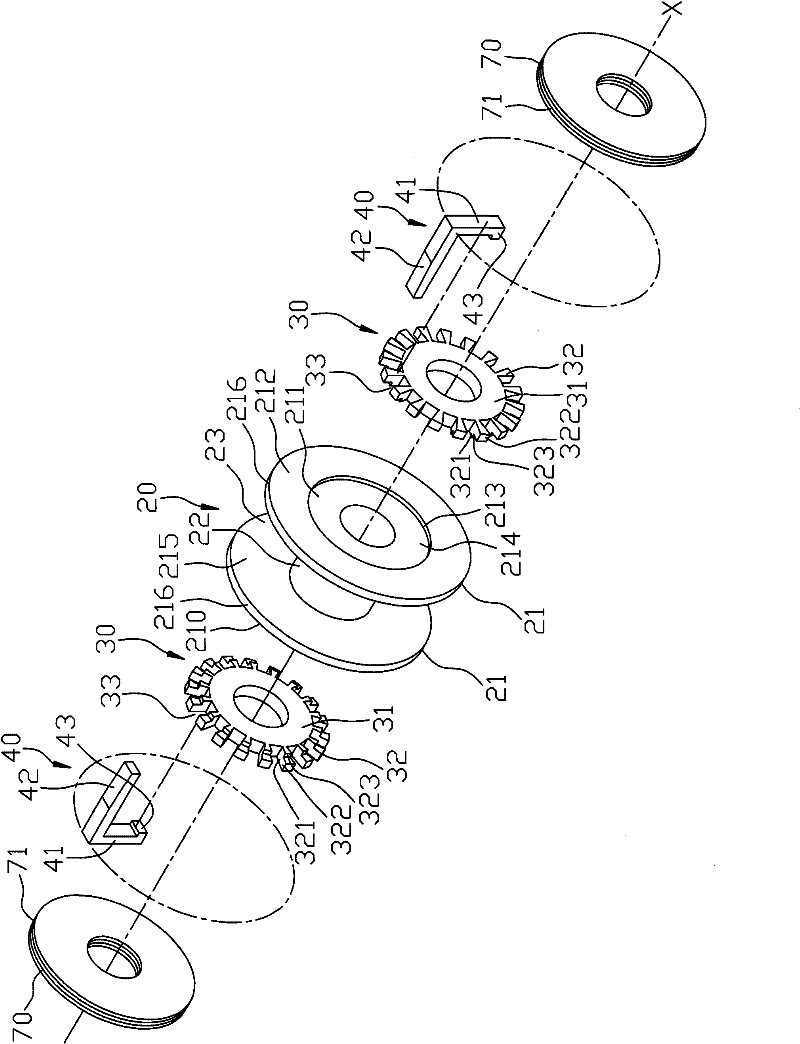

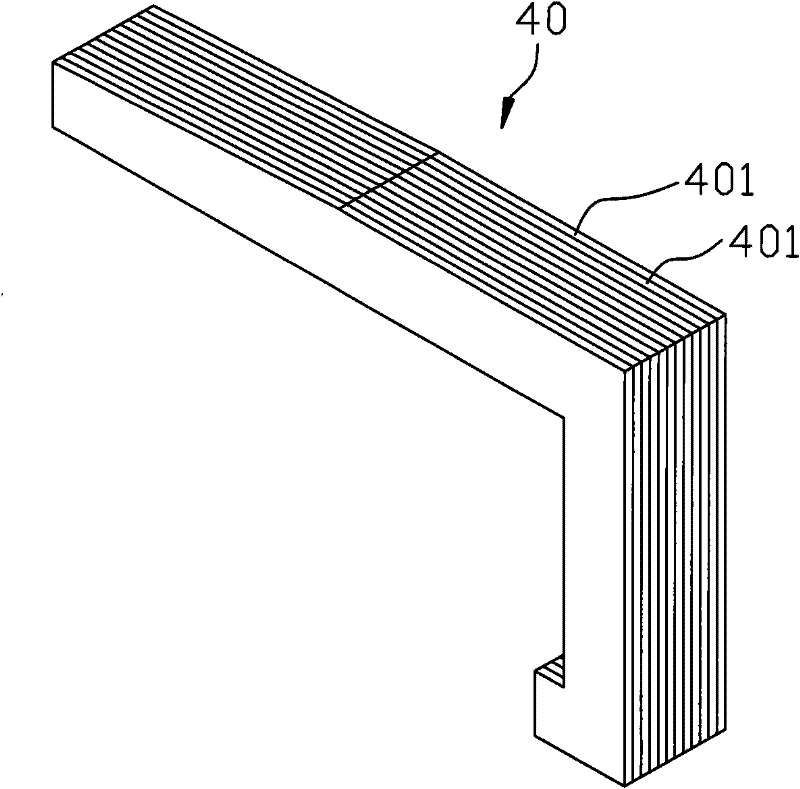

[0013] like figure 1 , 2 As shown, the first preferred embodiment of the generator hub 100 of the present invention includes a mandrel 10, a bobbin 20, two yoke disks 30, a plurality of yoke claws 40, a housing 50, a magnetic unit 60 and Two sets of isolation shutter sets 70.

[0014] The mandrel 10 extends along an axis X and includes a mounting section 11 , a retaining ring 12 located at a front side of the mounting section 11 , and a nut 13 screwed to a rear side of the mounting section 11 .

[0015] The bobbin 20 is fixed on the mounting section 11, and includes two side walls 21 spaced around the axis X, a cylinder wall 22 connected between the side walls 21 along the axis X, a A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com