Movable working vehicle with lifting protective screening

A technology for protective nets and work vehicles, applied in the field of mobile lift trucks, can solve the problems of high equipment investment, large space occupation, and lack of protection functions for train roof operations, and achieve the effect of widening the protection area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

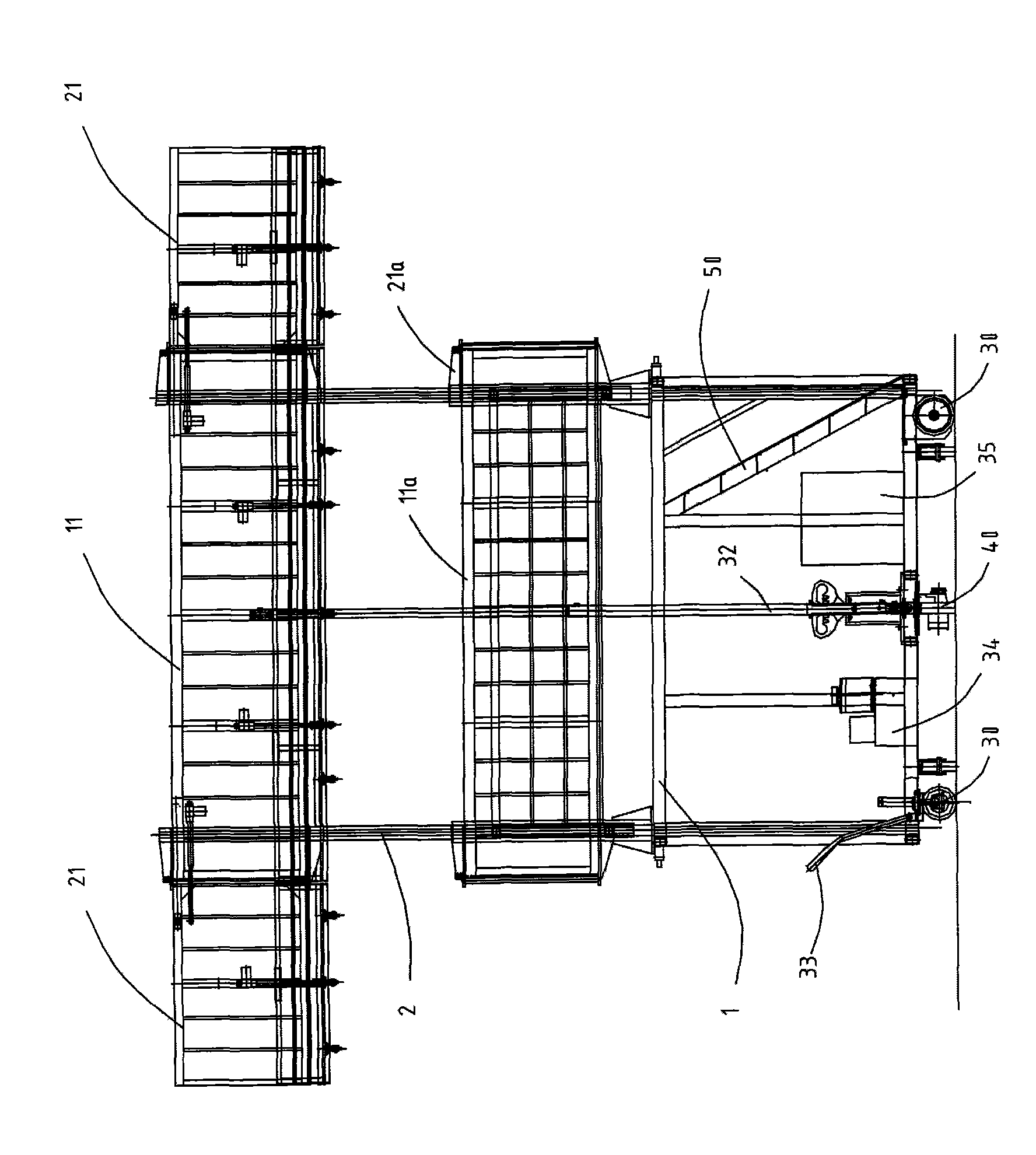

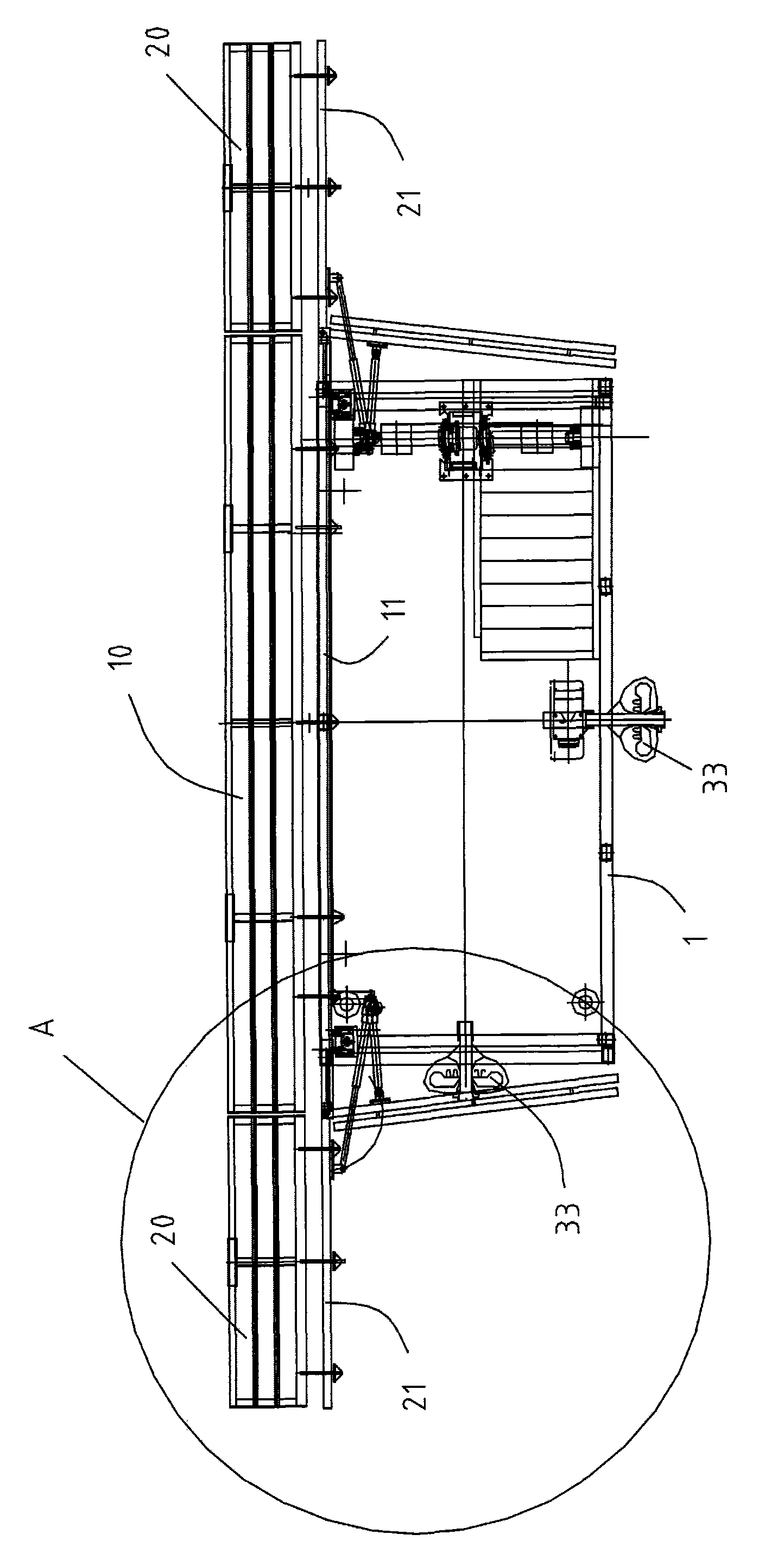

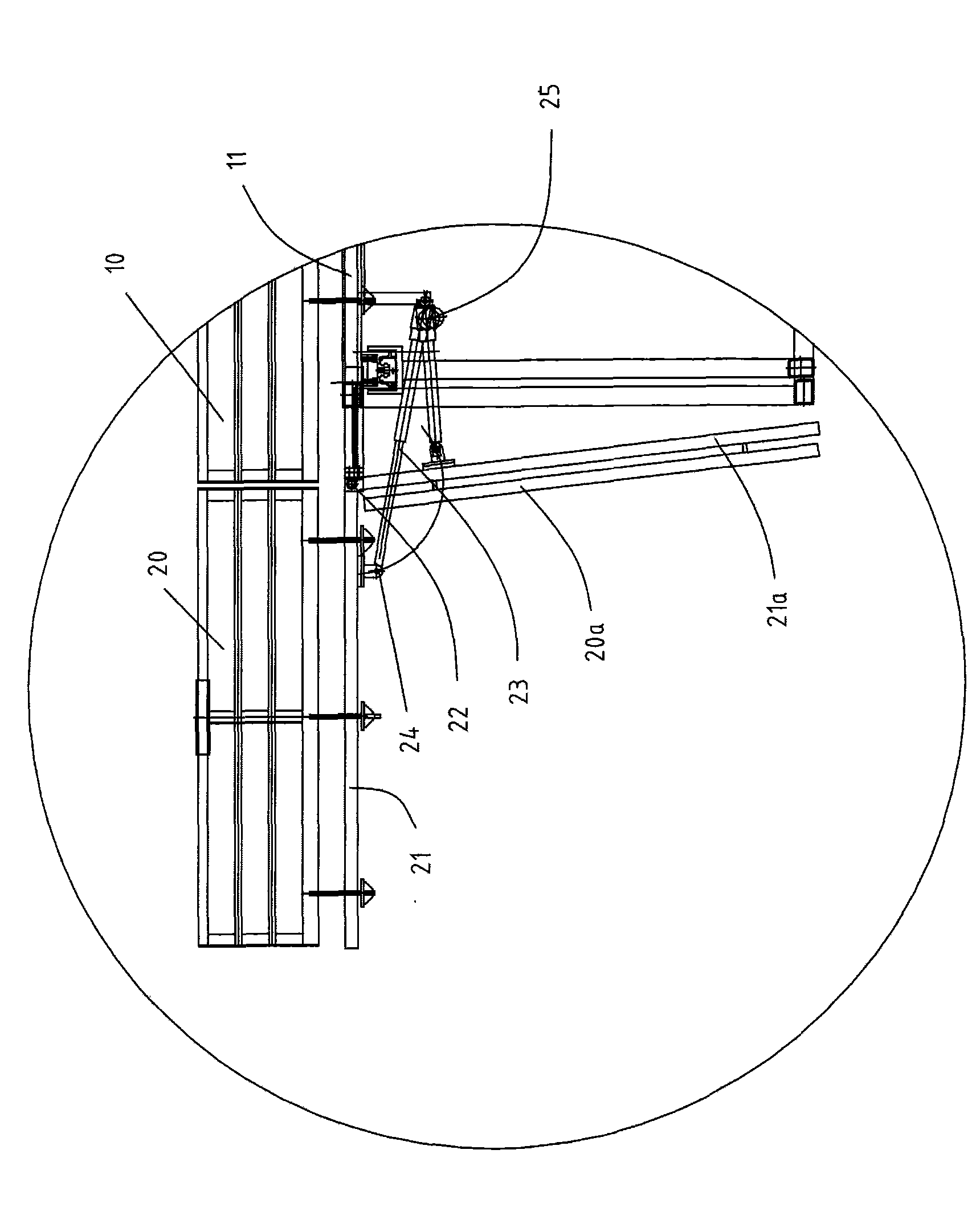

[0027] Such as figure 1 , figure 2 , Figure 4 As shown, the mobile lifting flap operation vehicle of the present invention includes an underframe 1, a linear guide rail mechanism 2, a middle flap 10, a side flap 20, a middle protective net 11 and a side protective net 21. Underframe 1 is welded with the square pipe of 90 * 60 * 5, and rectangular cuboid shape, on the top of underframe 1, a side of quadrilateral, linear guide rail mechanism 2 is set. A central protective net 11 is provided on the linear guide rail mechanism 2, and the central protective net 11 can move up and down along the linear guide rail mechanism 2, figure 1 The reference numerals 11 and 21 represent the state where the central protective net and the side protective net are at the uppermost state, and the numerals 11a and 21a represent the state when the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com