These fires usually require a substantial amount of time to extinguish, and therefore result in a significant portion of the burning structure being destroyed.

Additionally, the portion of the structure that survives the fire often has serious

water damage.

Consequently, paper records,

electronic equipment, including computers, and other sensitive components within these structures typically sustain significant

water damage.

Moreover, climate and

weather patterns may limit the use of water as the primary fire extinguishing substance.

This presents a practical challenge to prevent the water from freezing in the

firefighting devices when battling fires in those regions.

The use of sea water may also

pose an environmental

threat, as the salt deposited may cause environmental damage.

Unfortunately, in many instances the power cannot be shutdown.

Shutting off the power from a major

plant may plunge thousands or millions of people into

darkness and cause billions of dollars of damage.

Power plants lose thousands of dollars in revenue for every minute spent “turned off”.

A minor fire may cause a few hundred dollars in physical damages to wire insulation, but the

downtime may cost millions of dollars, especially if the water, foam, or

dry powder extinguishers are used and damage the

electrical equipment at a

power station.

Class D fires are also a challenge to extinguish using traditional methods.

The current fire extinguishers for use on class D fires are messy, powdered chemicals such as sand and various oxides or salts.

These materials have limited applicability and poor extinguishing performance.

They are typically applied with a

shovel and bucket, which is extremely slow and inefficient.

The use of a pressurized canister has been demonstrated, but its use tends to cause spreading of the fire, which is detrimental.

Additionally, many other methods of extinguishing such fires actually cause the fire to increase in severity and may actually cause explosions.

The use of these and certain other extinguishing agents have been banned due to their ability to cause explosions.

These pyrophoric chemicals are another type of hazardous material that cannot be extinguished using any type of currently available

fire extinguisher.

Most fire extinguishers cannot put these materials out because the presence of air or water actually causes these materials to burn.

The use of water, foams and other chemicals may cause significant damage to the surviving portion of the structure as well as present an environmental challenge to effectively

clean up the scene of the fire.

Hazardous material spills, whether combustible or not, also present a

significant risk to humans and the environment, and need to be neutralized rapidly and safely.

Containing these spills or releases is quite difficult.

Gaseous releases, such as

chlorine,

hydrochloric acid,

ammonia, and flammable natural gases are particularly hazardous based on their ability to rapidly drift in clouds, markedly increasing the ‘danger’ zone associated with the release.

There is no safe way to collect and neutralize these clouds, thus, relying on rapid control of the spill or release to limit the size of the toxic clouds formed.

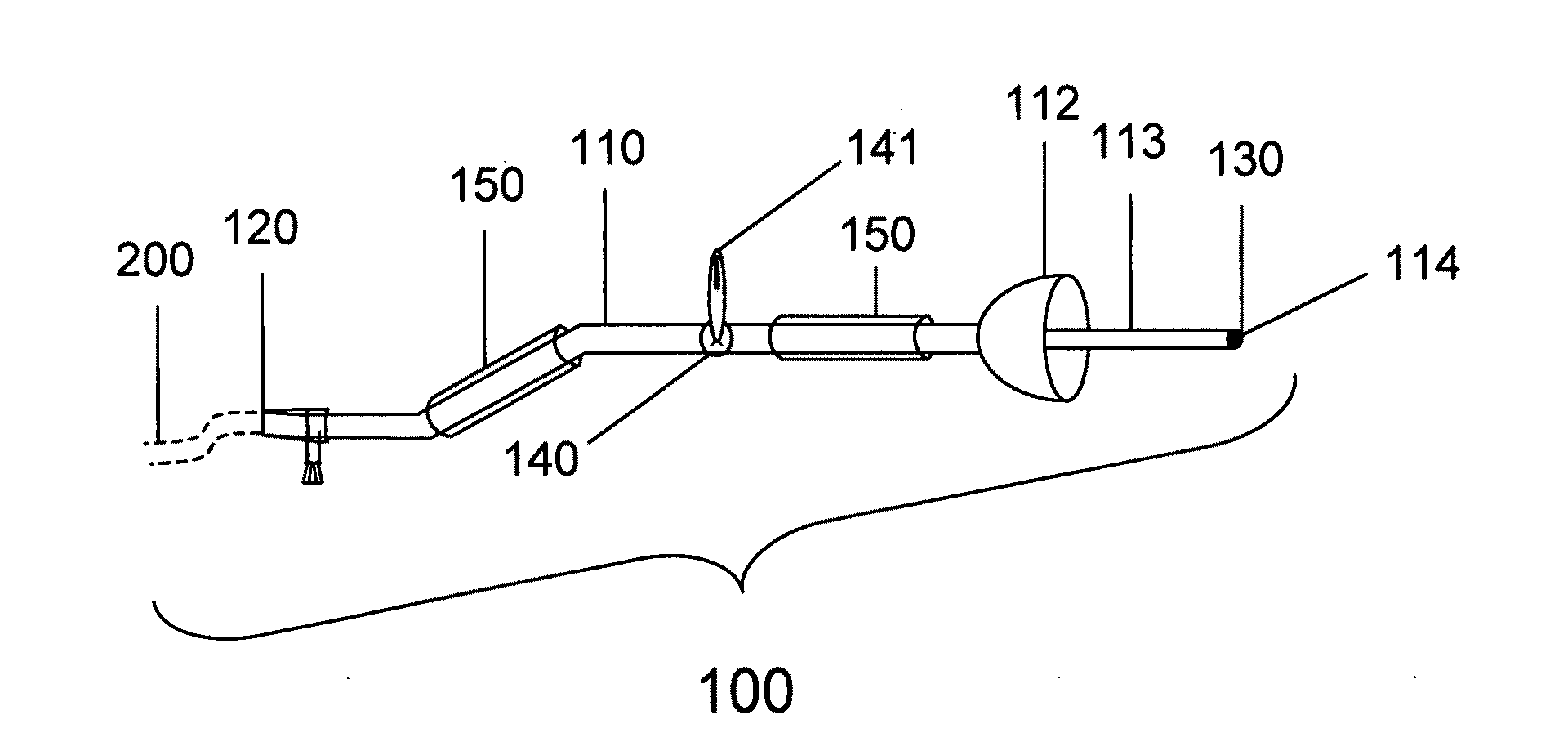

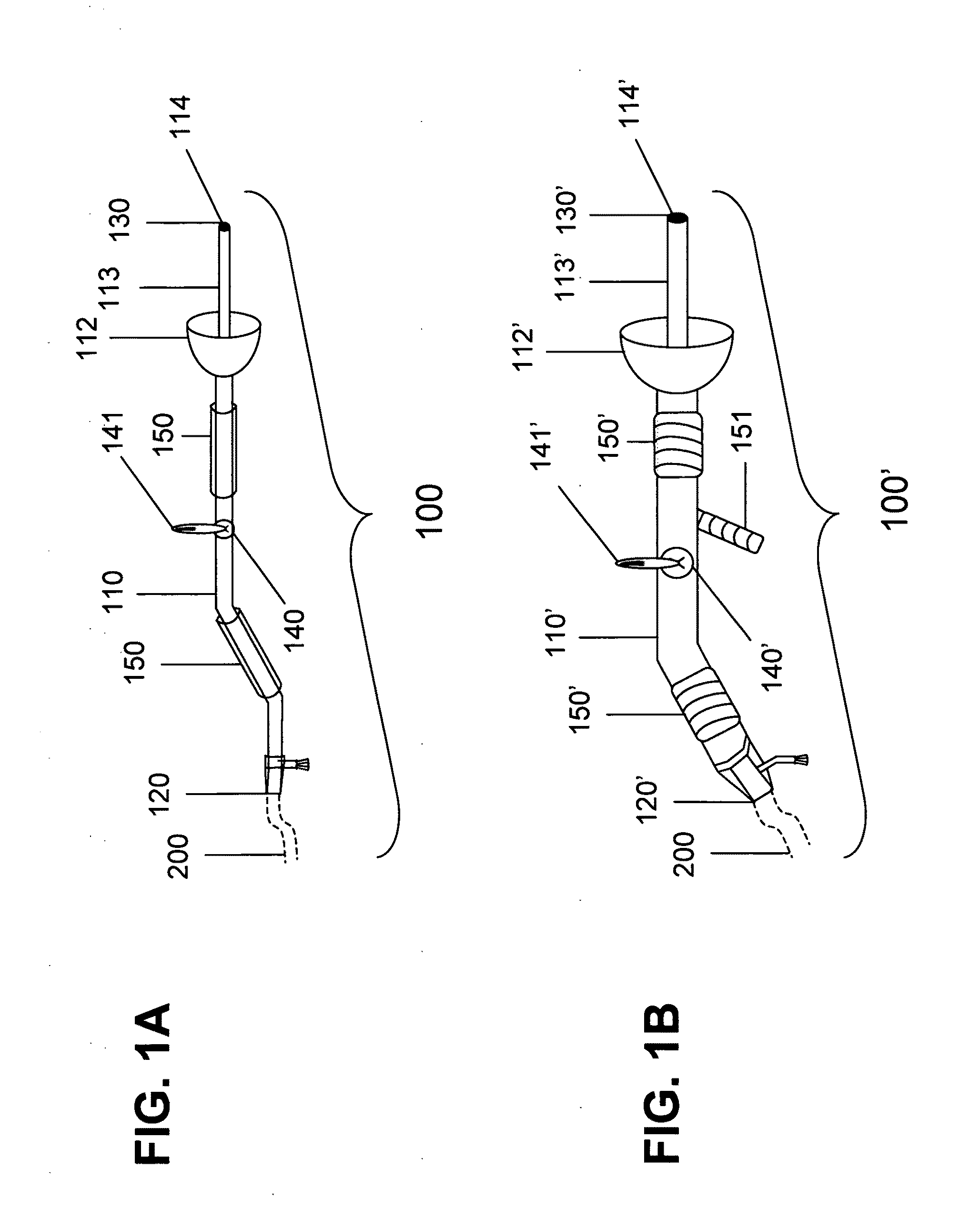

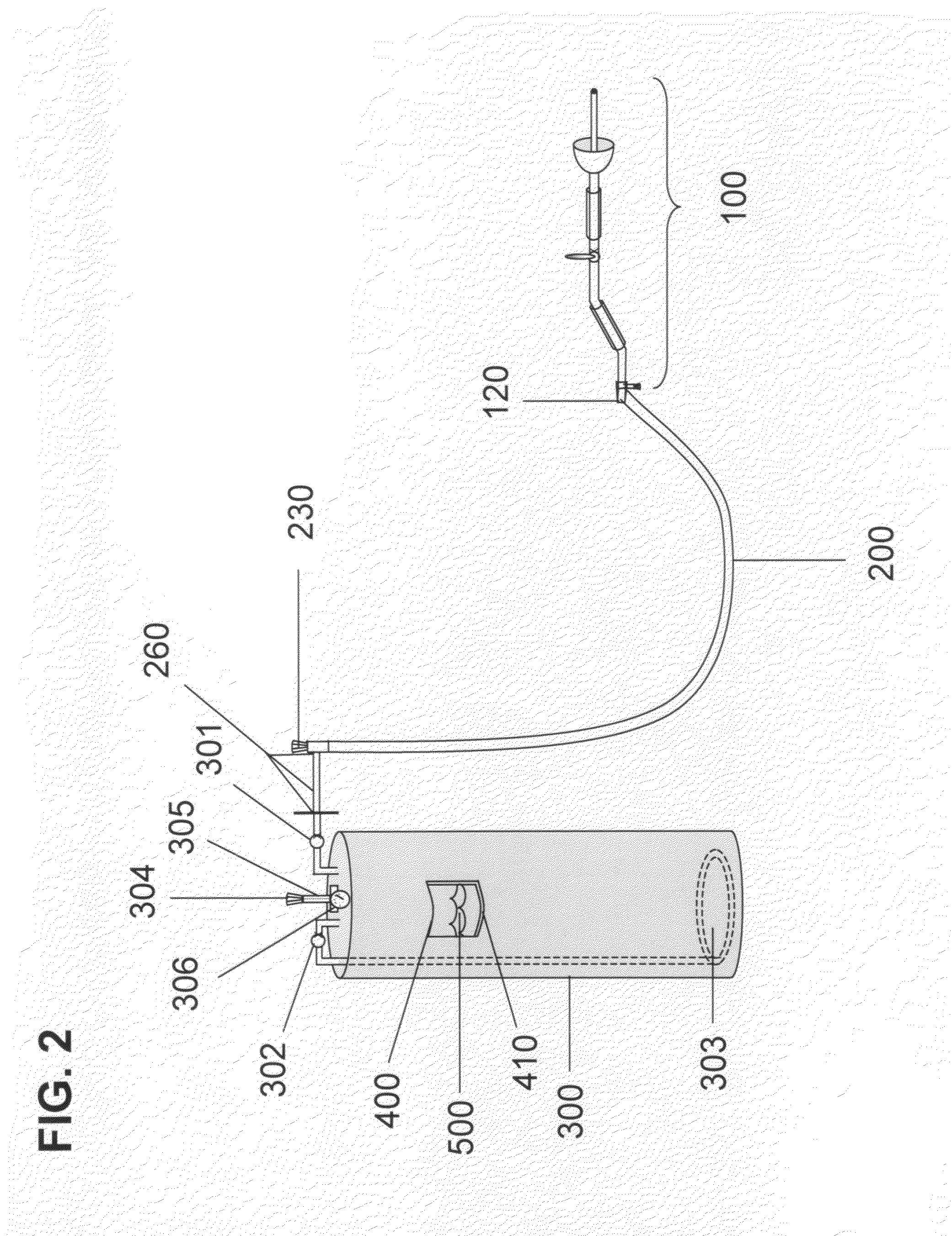

However, this technology has exhibited a variety of problems, issues, and drawbacks that have prevented their acceptance and use.

For example, previously described cryogenic systems often take the form of permanent installations attached to buildings, thereby limiting their usage to the structure to which they are attached.

Moreover, the mobile cryogenic systems described are very complex, bulky, and expensive, and require many operators to effectively function.

The aforementioned

firefighting and hazardous spill suppressing technologies have numerous shortcomings, including the inability to cool a fire rapidly, failing to prevent air form reaching a fire, being unable to reduce the hazardous nature of a chemical spill, the inability to neutralize hazardous gaseous clouds, failing to protect an area from additional damage, being difficult to

clean up afterwards, being harmful to the environment, and being harmful to humans and animals.

Additionally, no one agent is effective against all types of fires and hazardous materials spills.

Login to View More

Login to View More  Login to View More

Login to View More