Guardrail structure and guardrail lamp

A guardrail structure and guardrail light technology, applied in the directions of roads, lighting applications, traffic signals, etc., can solve the problems of not considering lamp protection, low impact energy, small protection area, etc., and achieve easy assembly and maintenance, reduce impact, and avoid glare. purpose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

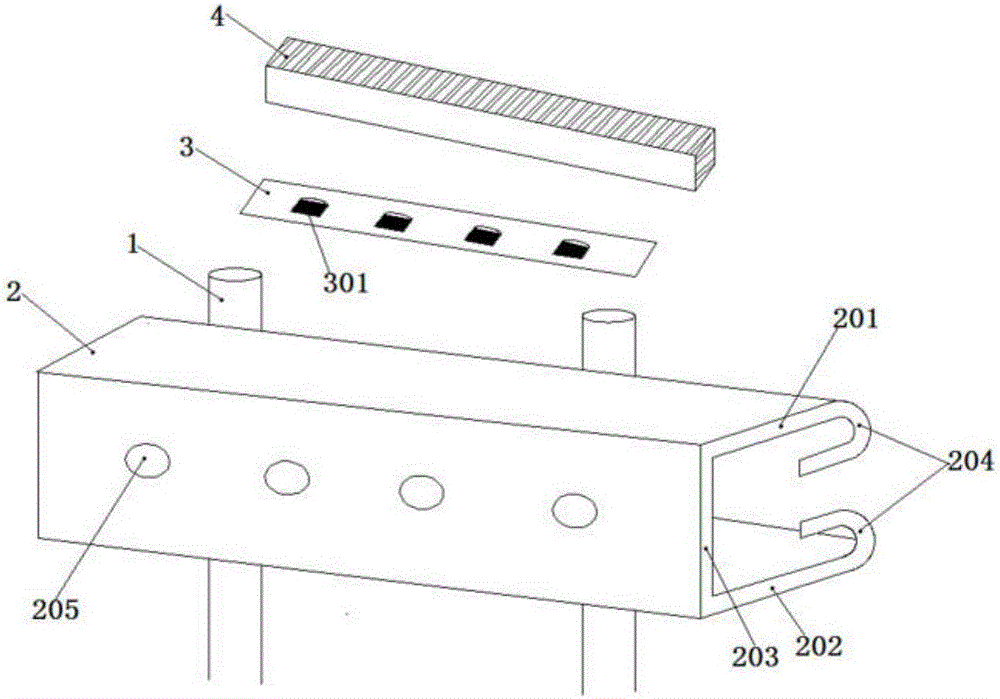

[0093] Such as figure 1 As shown, the guardrail structure in the first embodiment provided by the present invention includes a pillar 1, a guardrail body 2, a lamp assembly 3, and the guardrail body 2 is laterally fixed on a plurality of pillars 1 arranged at intervals. The guardrail body 2 includes a horizontal top plate 201, a horizontal bottom plate 202 and a vertical side plate 203. The other ends of the horizontal top plate 201 and the horizontal bottom plate 202 relative to the vertical side plate 203 are both bent toward the square groove cavity to form a U-shaped end 204.

[0094] The guardrail body 2 constitutes an energy absorbing part, the energy absorbing part is a non-elastic deformation buffer structure, and is a plate body. The plate body is bent and bent to form a groove with an opening toward the outside of the lane, between the upper and lower notches of the groove After relatively curved, it extends toward the inner side of the lane to form an end; the lamp ins...

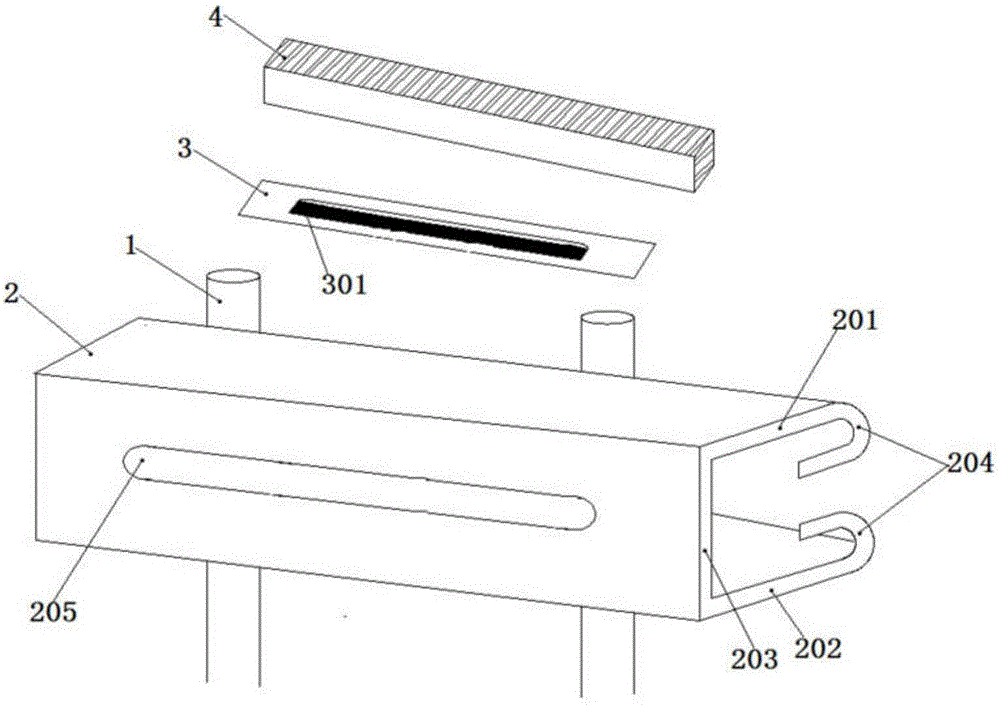

Embodiment approach

[0100] In the embodiment of the present invention, as a first implementation, the light trough 205 is arranged on the guardrail body 2 in a horizontal linear shape. Specifically, according to the actual installation method of the guardrail body 2, it can be installed on the horizontal top plate 201, A light trough 205 is provided in any one of the horizontal bottom plate 202 and the vertical side plate 203. In this embodiment, the LED light sources 301 will be arranged in a line shape, so that the light is linear. This embodiment includes, but is not limited to: (1) A plurality of light slots 205 are separately arranged on the horizontal top plate 201, the horizontal bottom plate 202 or the vertical side plate 203 of the guardrail body 2 along the transverse direction, and the multiple light slots 205 are arranged in a horizontal direction. Distributed in one or more rows; (2) According to the required luminous intensity, at least two of the horizontal top plate 201, the horizon...

no. 2 example

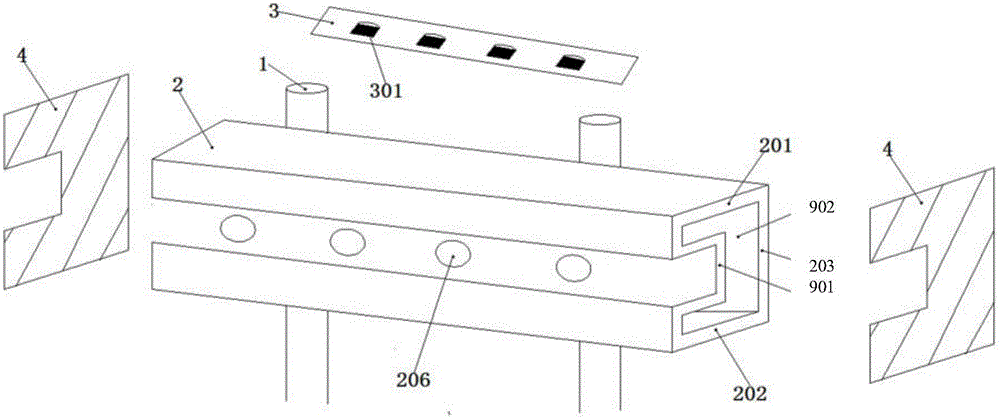

[0102] Such as image 3 As shown, the guardrail structure in the second embodiment provided by the present invention includes a pillar 1, a guardrail body 2, a lamp assembly 3, and the guardrail body 2 is laterally fixed on a plurality of pillars 1 arranged at intervals. The guardrail body 2 includes a horizontal top plate 201, a horizontal bottom plate 202, a vertical side plate 203 and a hat-shaped side plate 901.

[0103] The guardrail body 2 constitutes an energy absorbing part, the energy absorbing part is a non-elastic deformation buffer structure, at least a part of the energy absorbing part is located inside the lamp installation surface in the direction of the inner and outer sides of the lane; the guardrail body is a tube body; The cross-sectional profile is a concave figure; the lamp installation surface has a lamp slot notch; the maximum width of the energy absorbing part in the inner and outer directions of the lane is distributed at a different height position than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com