Automatic temperature-control LED hose lamp

An LED hose lamp and automatic temperature control technology, which is applied to the circuit layout of electric lamps, loss prevention measures of lighting devices, lighting and heating equipment, etc. , the effect of good white balance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

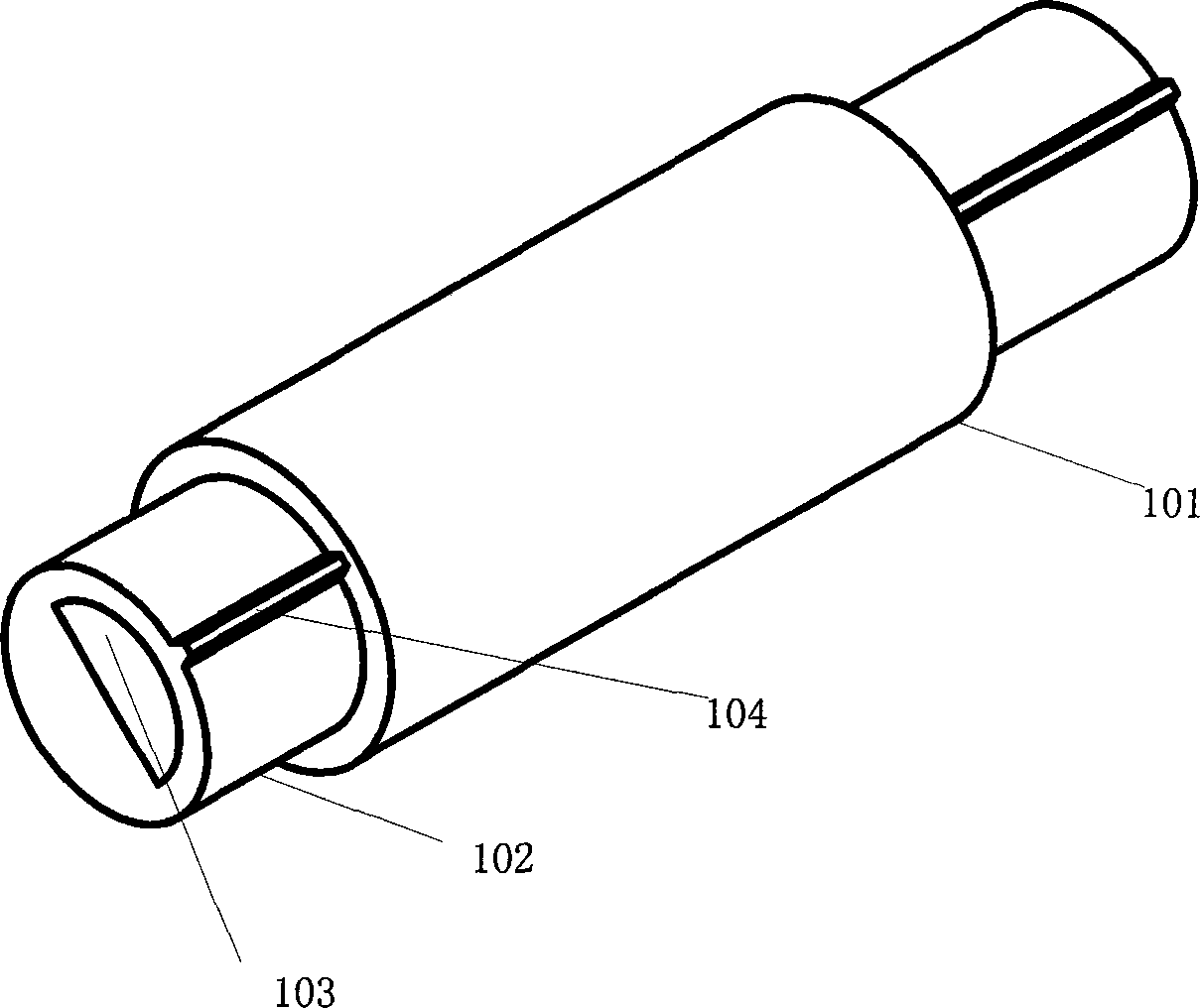

[0039] Such as figure 1 and figure 2 As shown, an automatic temperature-controlled LED hose lamp includes a transparent lamp tube 101, a flexible inner intestine 102, a lamp body 105 and an automatic temperature control circuit 100; the transparent lamp tube 101 and the flexible inner intestine can be made of thermoplastic flame-retardant Insulated plastic PVC, the light-transmitting lamp tube 101 is hermetically wrapped outside the flexible inner intestine 102, and a cavity 103 is arranged inside the flexible inner intestine 102. The shape of the cavity in this embodiment is semicircular, and it can also be other shapes such as rectangle, triangle, etc. , the lamp body 105 is placed inside the cavity 103 of the flexible inner intestine 102, and the lamp body includes: a flexible PCB board, an LED light-emitting unit arranged on the flexible PCB board, and a chip arranged on the flexible PCB board to control the light emission of the LED light-emitting unit; The LED light-em...

Embodiment 2

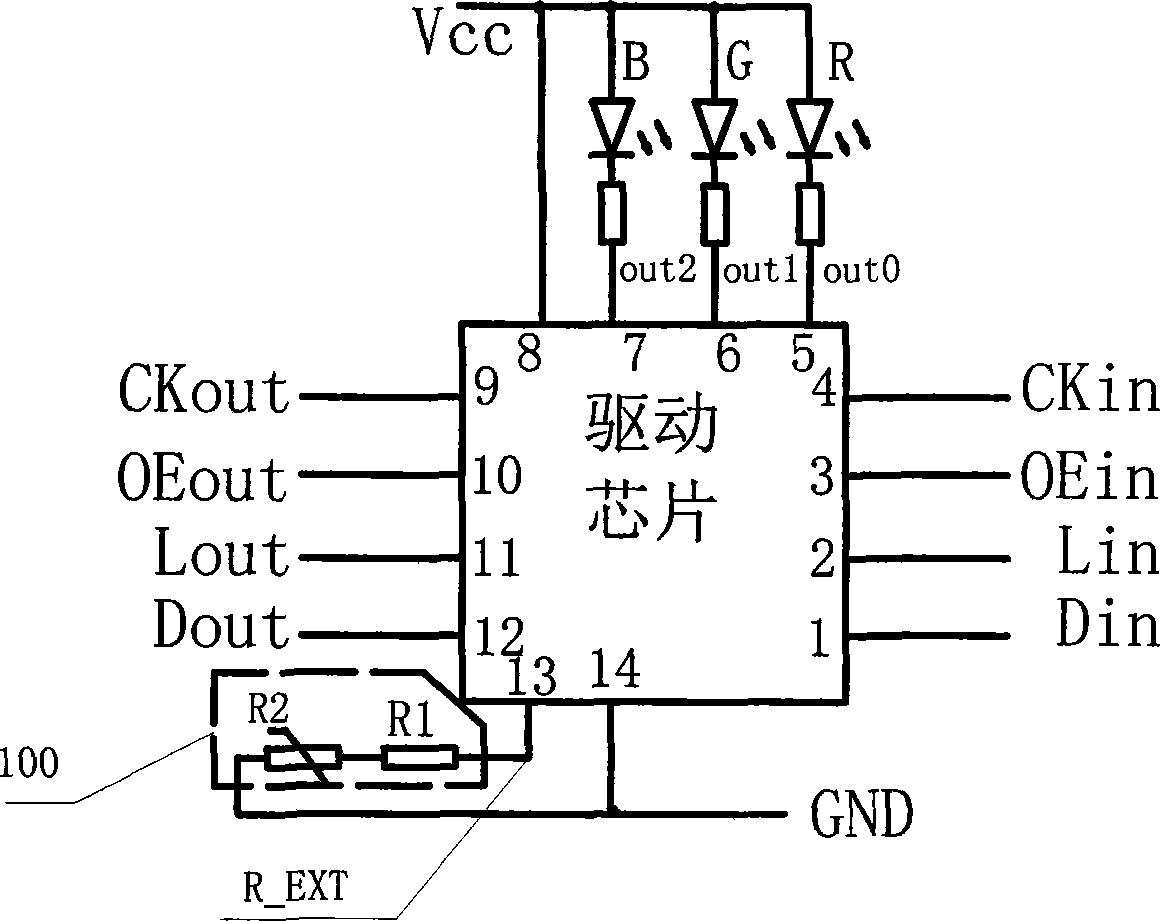

[0045] Such as figure 2 Shown is a circuit structure in the application of automatic temperature-controlled hose lights. The driver chip adopts a constant current driver chip with three drive output terminals OUT1, OUT2 and OUT3. The 13th pin of the chip is the input terminal R_EXT of the external resistor. Adjust the output current of the constant current output terminals OUT1, OUT2 and OUT3 through the resistance value of the resistor connected to the pin, the formula is I OUT =V R_EXT / (R1+R2), where V R_EXTR_EXT pin voltage, R1 is the resistance of the current limiting resistor, R2 is the resistance of the thermistor, the LED light-emitting unit consists of a red light-emitting diode R, a green light-emitting diode G, a blue light-emitting diode B and resistor R1, Composed of R2 and R3, the LED lights are connected in series with R1, R2, and R3 respectively; the power supply positive line VCC and the power supply negative line GND provide voltage to the circuit; the hos...

Embodiment 3

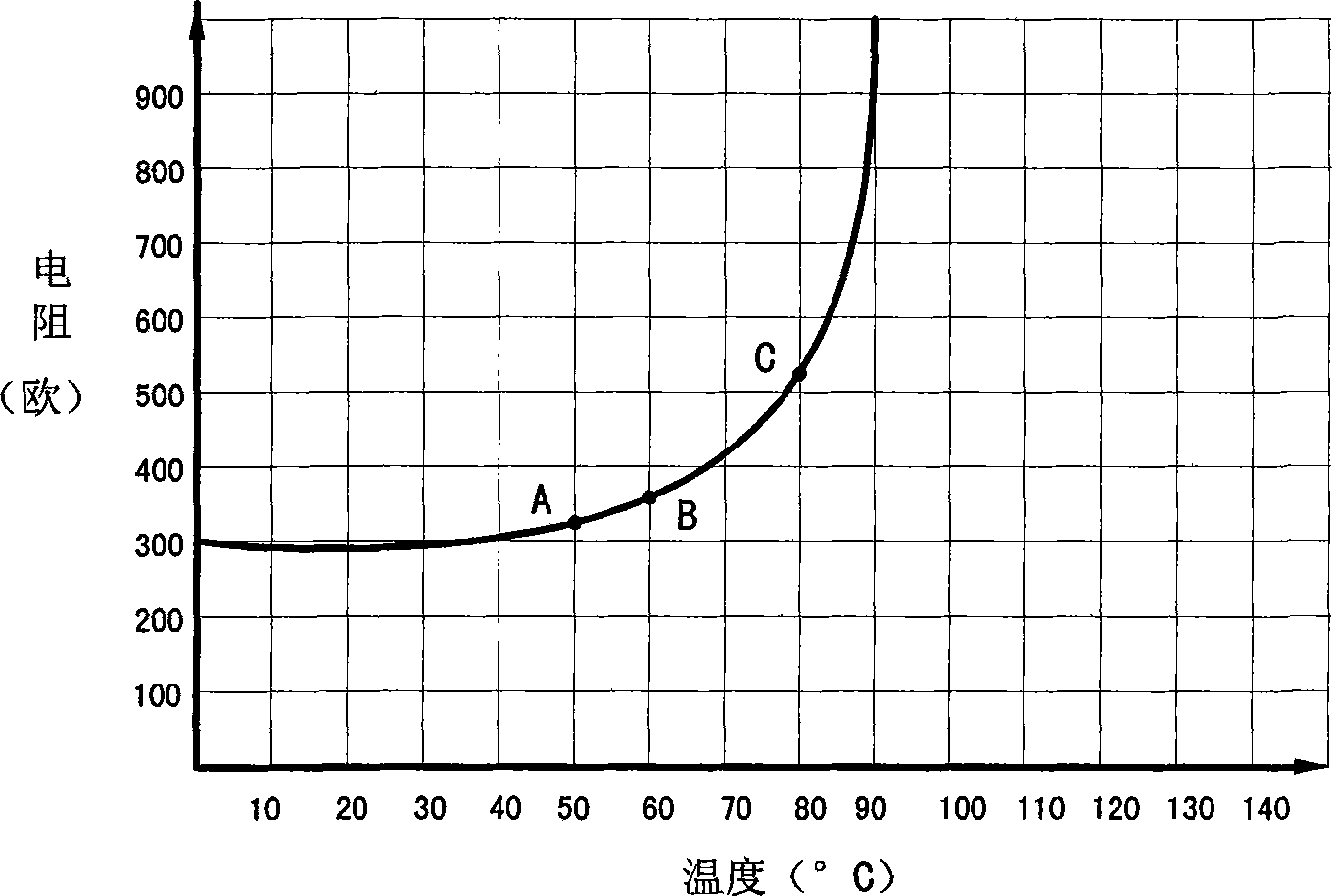

[0047] On the basis of the above-mentioned embodiments, this embodiment preferably adopts a positive temperature coefficient (PTC, positive temperature coefficient) thermistor R2, such as image 3 As shown, it is the resistance-temperature curve of the positive temperature coefficient thermistor. Since the optimal operating temperature of the LED lamp and the LED driver chip is 50°C to 80°C (as shown by points A and C in the figure), it is higher than There is a risk of damage at 80°C. Therefore, the temperature must be controlled before the temperature rises to 80°C. Therefore, the Curie point is preferably 50°C to 80°C, and the best is 60°C (as shown by point B in the figure). Shown) PTC thermistor.

[0048] A type of positive temperature coefficient thermistor, the resistance value of the positive temperature coefficient thermistor shows a stepwise increase with the increase of the temperature of the PTC thermistor body. The higher the temperature, the greater the resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com