A heat conduction closed continuous scrubbing and leaching equipment

A closed and leaching technology, applied in the directions of silica and silicon oxide, can solve the problems such as the great harm to the external environment of the exhaust gas and the difficulty of recycling the medium, so as to enhance the scrubbing and leaching effect, reduce the equipment cost, and increase the chance of friction and collision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

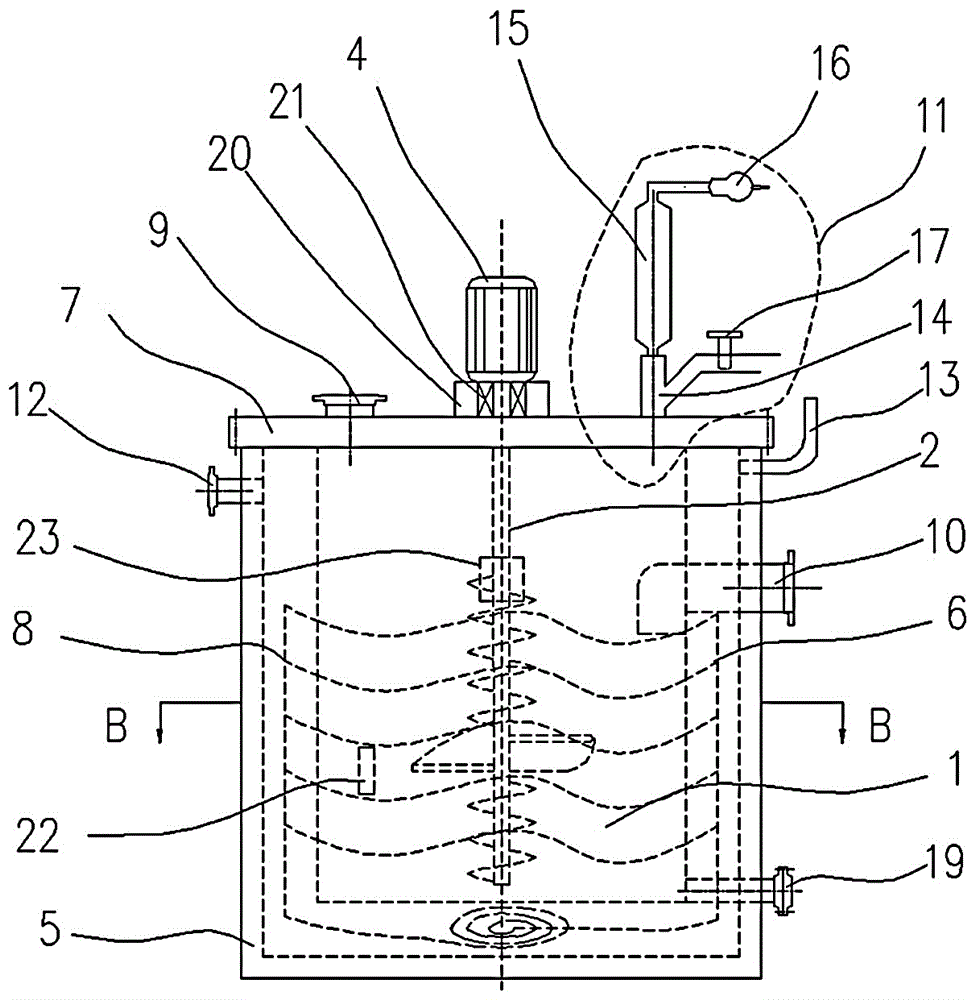

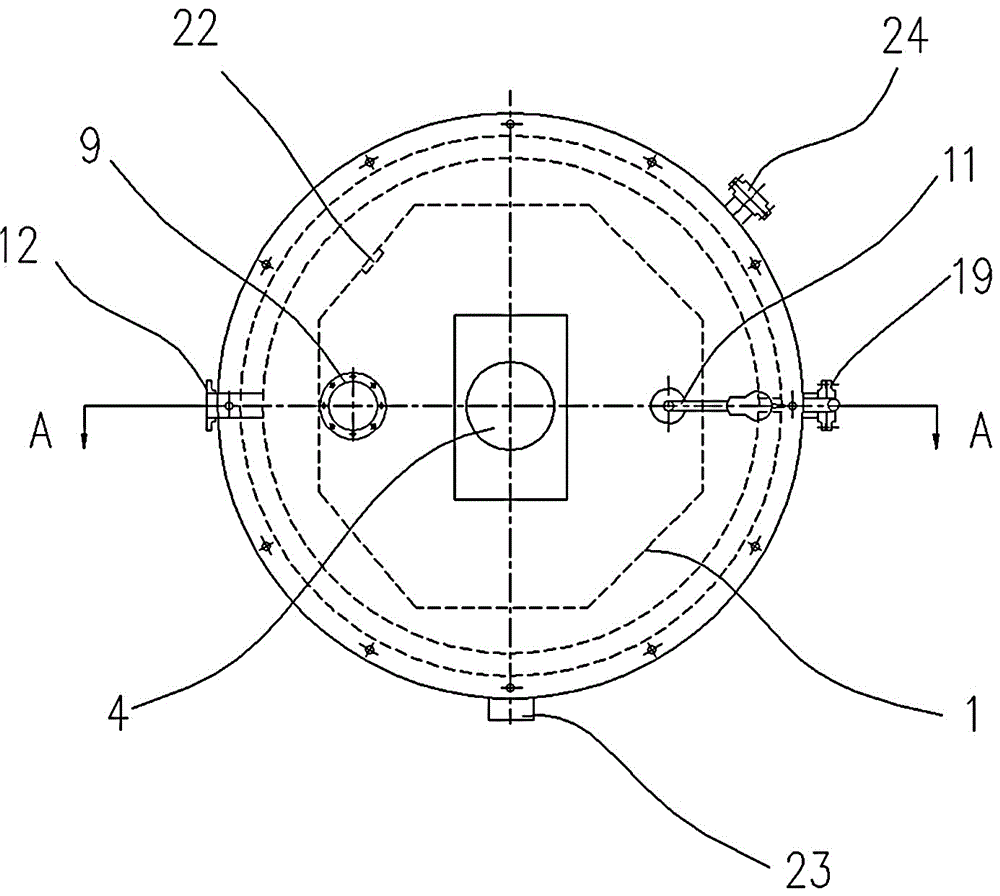

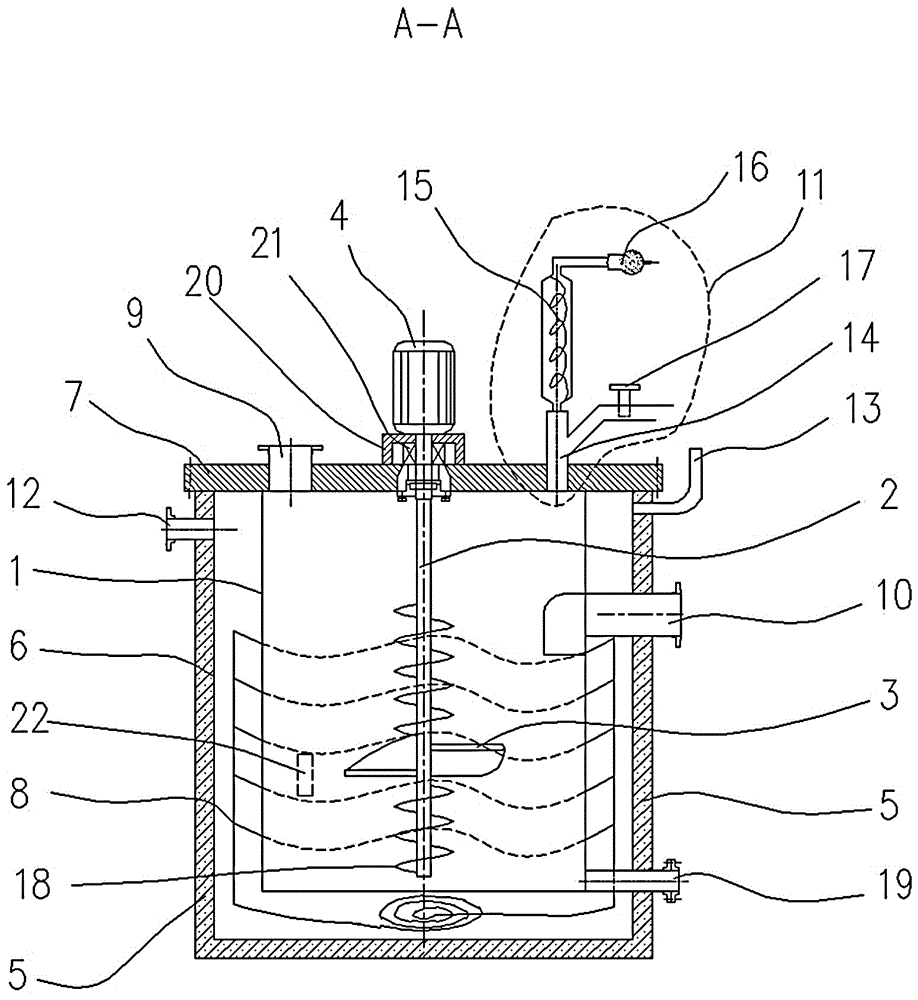

[0030] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a heat conduction closed continuous scrubbing and leaching equipment provided by the present invention includes a barrel-shaped leaching tank 1 with a regular octagonal structure and an upper end opening. The leaching tank 1 is made of stainless steel and is lined with polytetrafluoroethylene. Made, the leaching tank 1 rotates with a stirring shaft 2, and the stirring shaft 2 in the leaching tank 1 is sequentially connected to a section of spiral impeller 18, a pair of movable impellers 3 and another section of spiral impeller 18 from top to bottom, and the stirring shaft 2. One end protruding from the leaching tank 1 is connected with the externally fixed driving motor 4 in rotation.

[0031] A heat-conducting medium storage tank 6 with an insulating layer 5 is provided outside the leaching tank 1. The heat-conducting medium storage tank 6 is a cylindrical structure larger in size than the leaching tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com