Magnetic floatation machine

A flotation machine and magnetic technology, applied in flotation, solid separation, etc., can solve problems affecting mineral recovery, inconvenient operation and control, and limited range of influence, so as to avoid errors, improve recovery, and reduce experimental errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

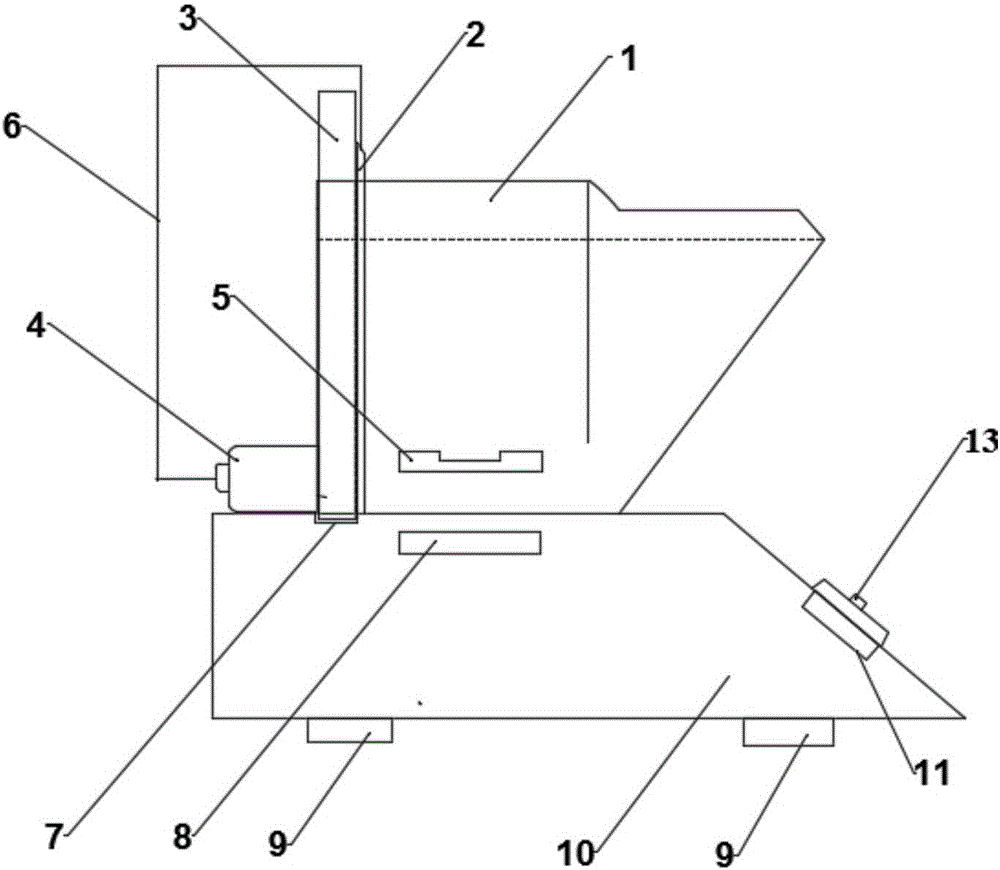

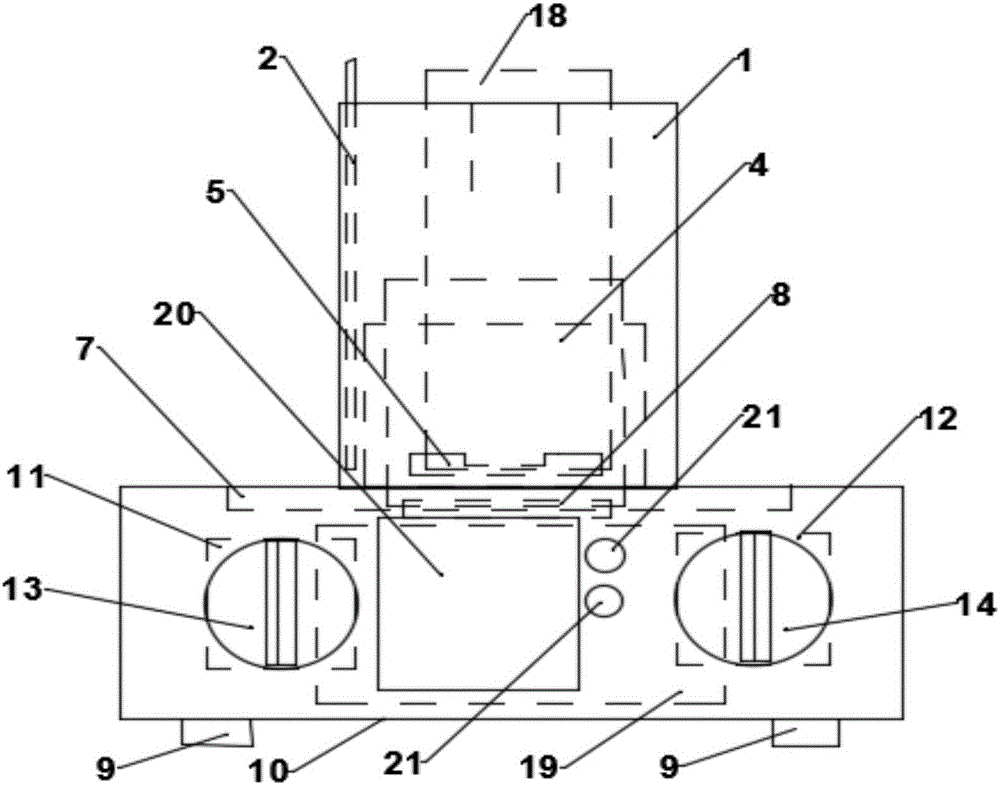

[0023] Such as figure 1 and figure 2 As shown, the present embodiment provides a magnetic flotation machine, including a flotation cell 1, a base 10, an air intake pipe 2, an air pump 4, a stirring module, a speed control module, and a temperature control module; the flotation cell 1 is arranged on The upper part of the base 10 is provided with an air intake pipe 2 inside, and the air intake pipe 2 is connected with the air pump 4 through an air conduction hose 6; The stirring mechanism in 10, the stirring mechanism includes a motor, an inner magnetic rotor 8 connected to the motor shaft; the speed control module and the temperature control module are both arranged in the base 10 .

Embodiment 2

[0025] Such as figure 1 and figure 2 As shown, the embodiment provides a magnetic flotation machine. What is different from embodiment 1 is that the speed control module of the magnetic flotation machine in this embodiment includes a first resistor 11 connected to the motor and a speed adjustment knob 13; The magnetic flotation machine also includes an air charge control module, the air charge control module includes a second resistor and an air charge adjusting knob 14, and the second resistor and the air charge adjusting knob 14 are connected to an air pump through a circuit.

Embodiment 3

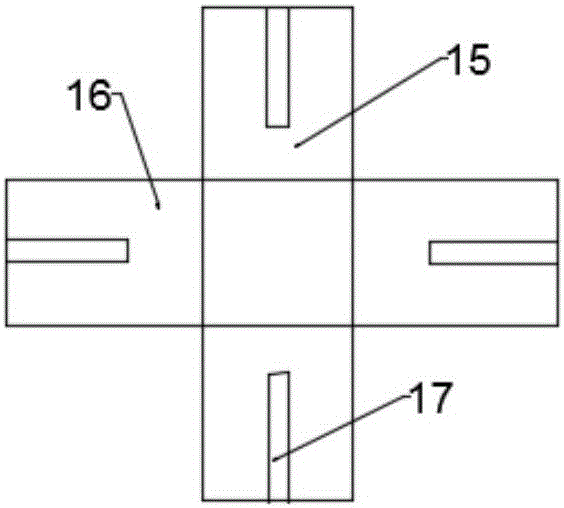

[0027] Such as Figure 1 to Figure 3 As shown, the embodiment provides a magnetic flotation machine. What is different from Embodiment 3 is that a slot is provided on the back of the flotation cell, and the fixed inserting plate is inserted into the fixed slot on the upper part of the base through the slot. The flotation cell is fixed on the base; the magnetic rotor 5 is fixedly composed of a magnetic part 15 and a nonmagnetic part 16, and a baffle 17 is designed on each corner of the magnetic stirring rotor 5; the temperature control module includes a line connection The temperature adjustment plate 18, the temperature control device 19, the temperature display screen 20 and the temperature setting button 21; the temperature adjustment plate 18 is composed of a heat dissipation plate 22 with a heating wire, a heat insulating material 23, a temperature probe 24, and a fixed spring 25. The temperature regulating plate is fixed on the inner wall of the flotation cell 1 by two fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com