Automatic storing and fetching system of goods

A technology for automatic access and item storage, which is applied to storage devices, instruments, inductive record carriers, etc. It can solve the problems of unmanned operation and complete automation, so as to improve the efficiency and accuracy of warehouse entry and exit. and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, the ground rail 11 is used as the guide rail.

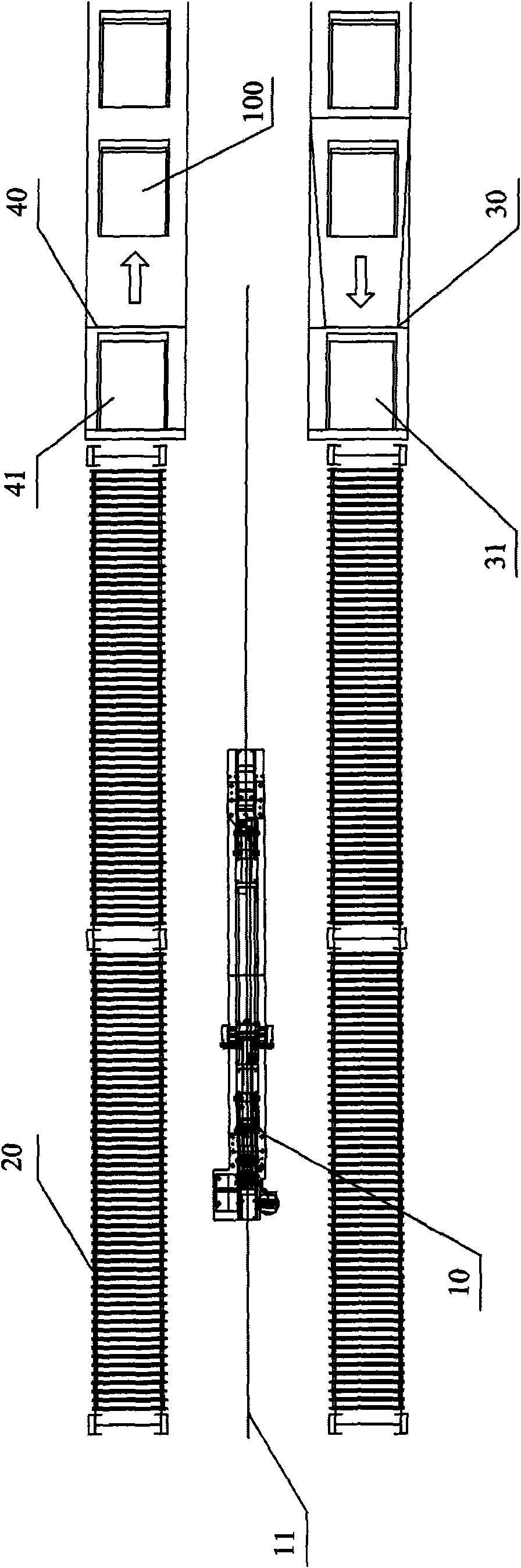

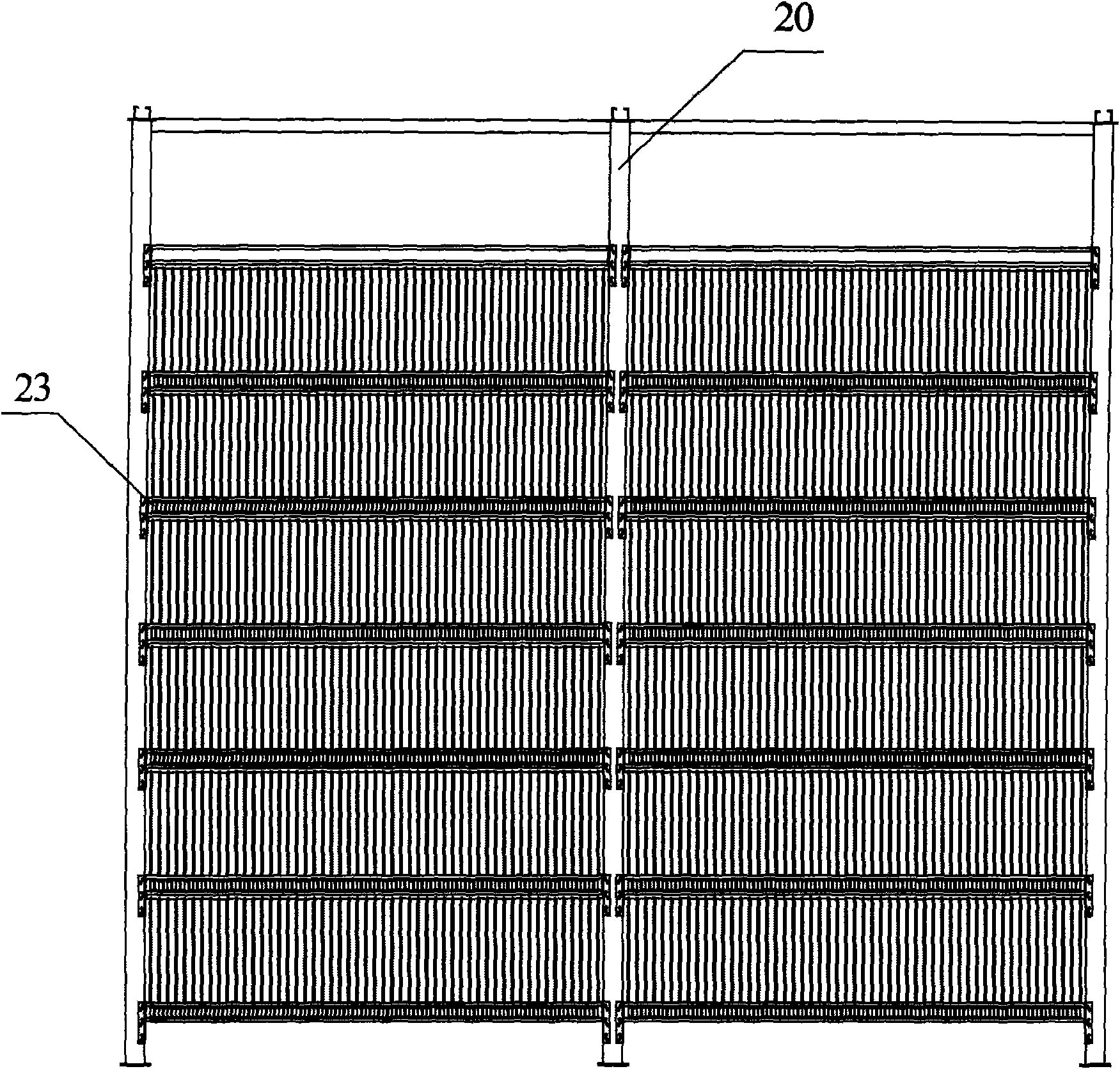

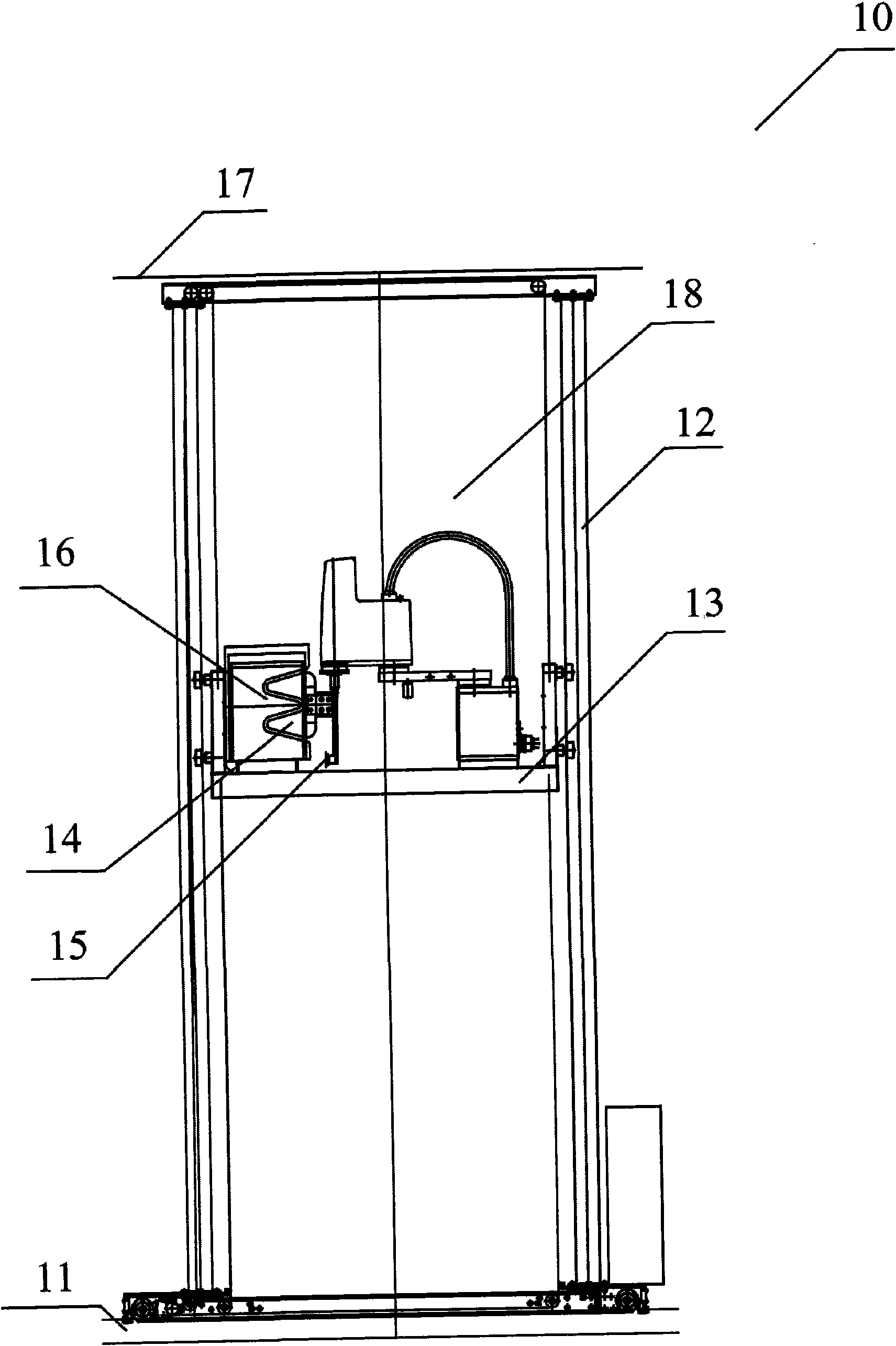

[0038] Such as figure 1 As shown, the article access system involved in this embodiment includes a floor rail 11, an access device 10 capable of sliding on the floor rail 11, shelves 20 arranged on both sides of the floor rail 11, and a storage system next to the shelf 20. Conveyor 30 and outbound conveyor 40. A warehouse-in turnover mechanism 31 is provided between the warehouse-in conveyor 30 and one side of the shelf 20 , and a warehouse-out turnover mechanism 41 is provided between the warehouse-out conveyor 40 and the other shelf 20 . When warehousing, the article 100 is transferred to the warehousing turning mechanism 31 through the warehousing conveyor 30, and after being turned over by the warehousing turning mechanism 31 to a suitable angle, it is transported to the shelf by the access device 10 that slides to the vicinity of the warehousing turning mechanism 31 20; when going out of the ware...

Embodiment 2

[0053] In Embodiment 1, the storage method of the article 100 perpendicular to the ground rail 11 has been described, but in this embodiment, as Figure 17 As shown, the article 100 is stored parallel to the floor rail 11 .

[0054] Such as Figure 17 As shown, when the storage mode of the article 100 is parallel to the ground rail 11, the shelf 200 includes several article boxes 201, and the storage space of the article box 201 is the same as that of the shelf 20 in Embodiment 1, and several storage units are divided by the spacer . When accessing the article 100, the manipulator 14 or another manipulator (not shown) first pulls the article box 201 out to Figure 17 In the state shown, specifically, it is pulled out onto the lifting platform (not shown) of the access device, and then the items 100 in the item box 201 are accessed parallel to the ground rail 11 . After the item 100 is accessed, the manipulator 14 or another manipulator (not shown) pushes the item box 201 ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com