Glasses storing, taking and disinfecting device

A technology for disinfection devices and glasses, which is applied in the direction of unloading devices, packaging, transportation and packaging, etc. It can solve the problems of insufficient disinfection, low efficiency, and non-sterilization, and achieve the effects of improving sanitation, good experience, and improving operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further describe the technical features and effects of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

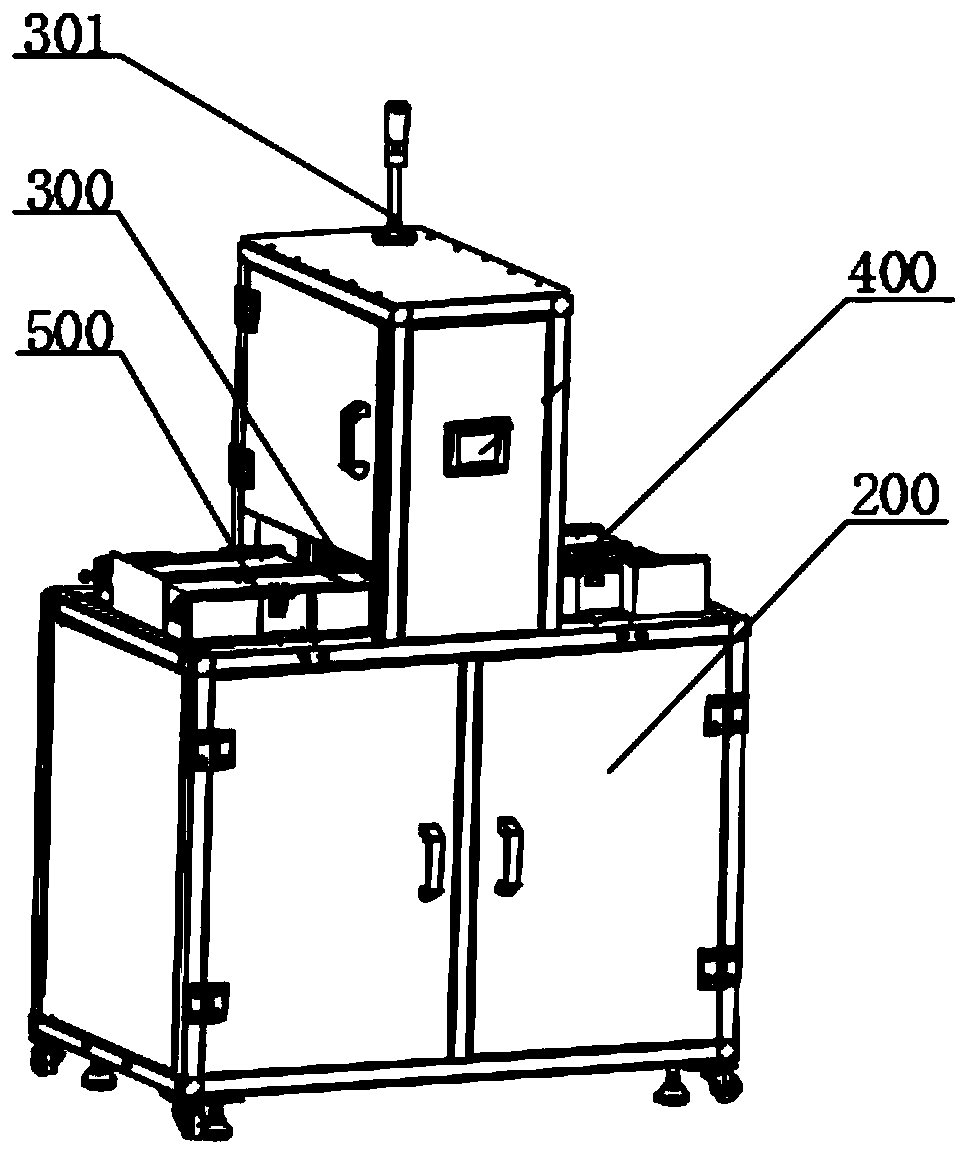

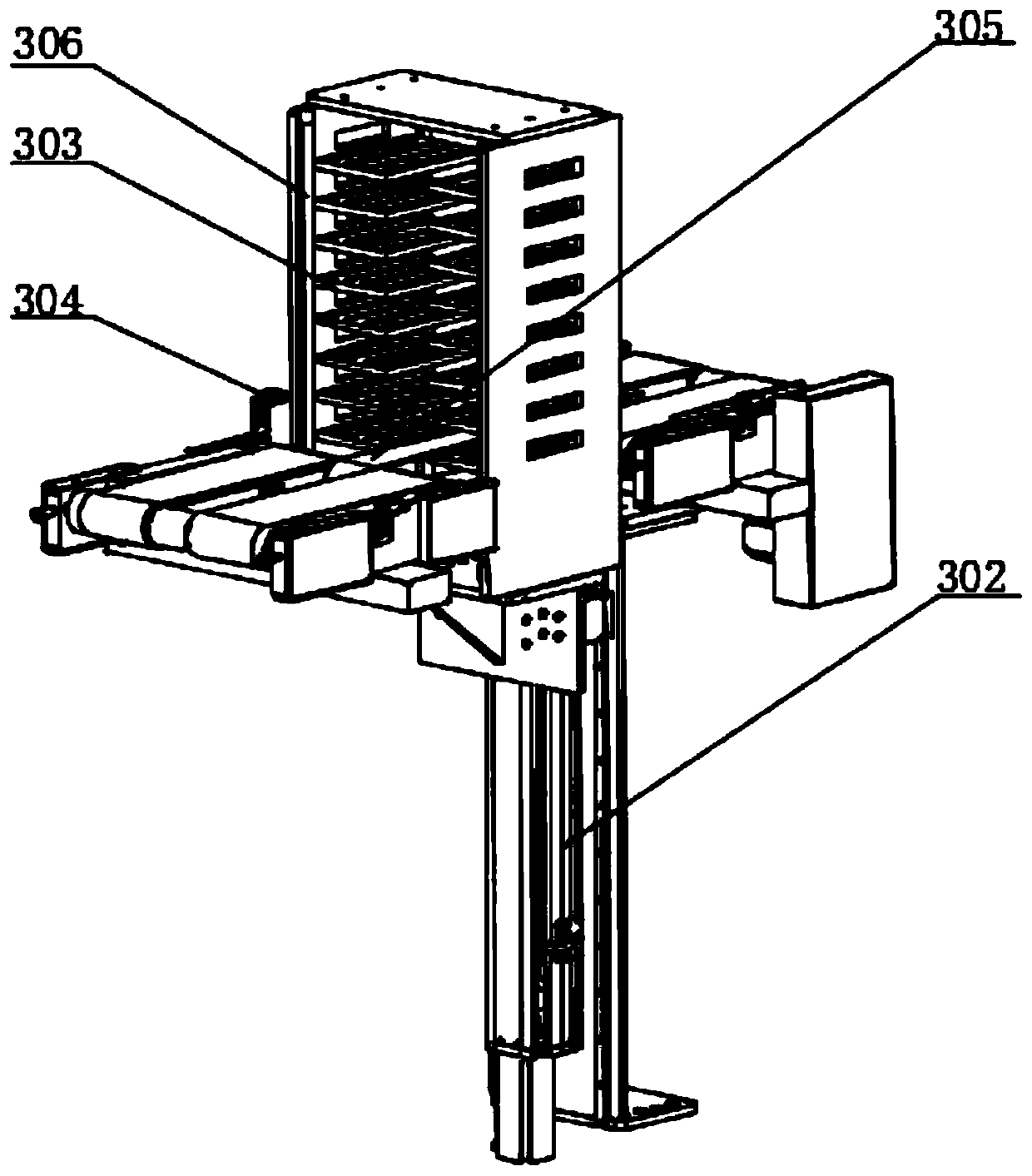

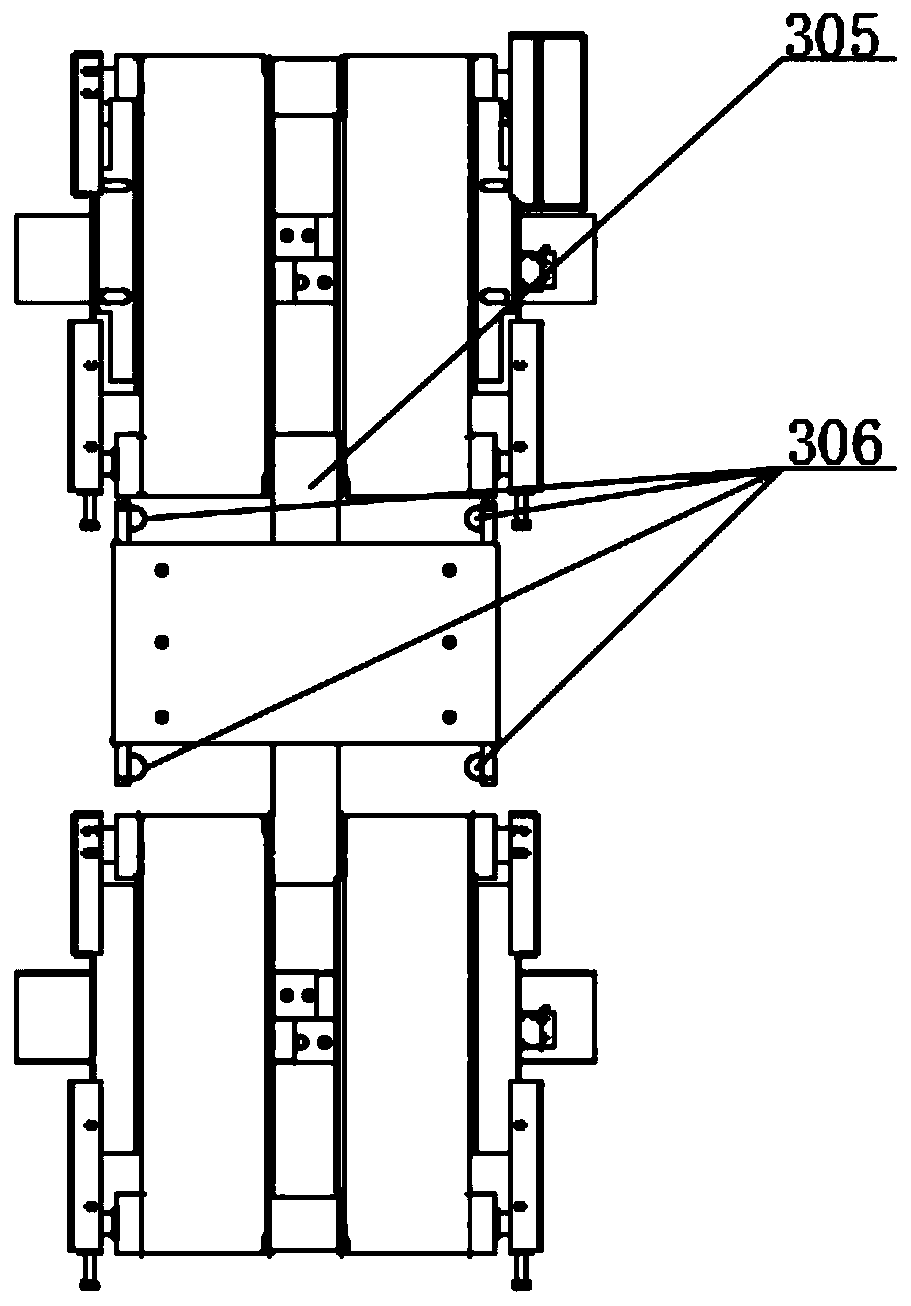

[0024] Such as Figure 1-7 As shown, a glasses access and disinfection device includes: a base 200, a cache unit 300, a storage unit 400 and a pick-up unit 500; the cache unit 300 is set on the base 200, and the storage unit 400 is set on the cache unit 300 to drive the container to move to the cache unit 300, and the pick-up unit 500 is arranged on the other side of the cache unit 300 to drive the container (which can be a tray, a bracket, etc.) to move out of the cache unit 300; the cache unit 300 is equipped with a disinfection device.

[0025] The storage unit 400 includes: a first synchronous wheel 401, a synchronous belt 402, a motor 403 (servo motor), a second belt 404, a first frame 405, a first driving shaft 406, a first driven shaft 407, a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com