Sideways drift correction device

A drift correction and lateral technology, applied in road repair, roads, roads, etc., can solve problems such as inaccurate construction of structures and inability to detect lateral drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

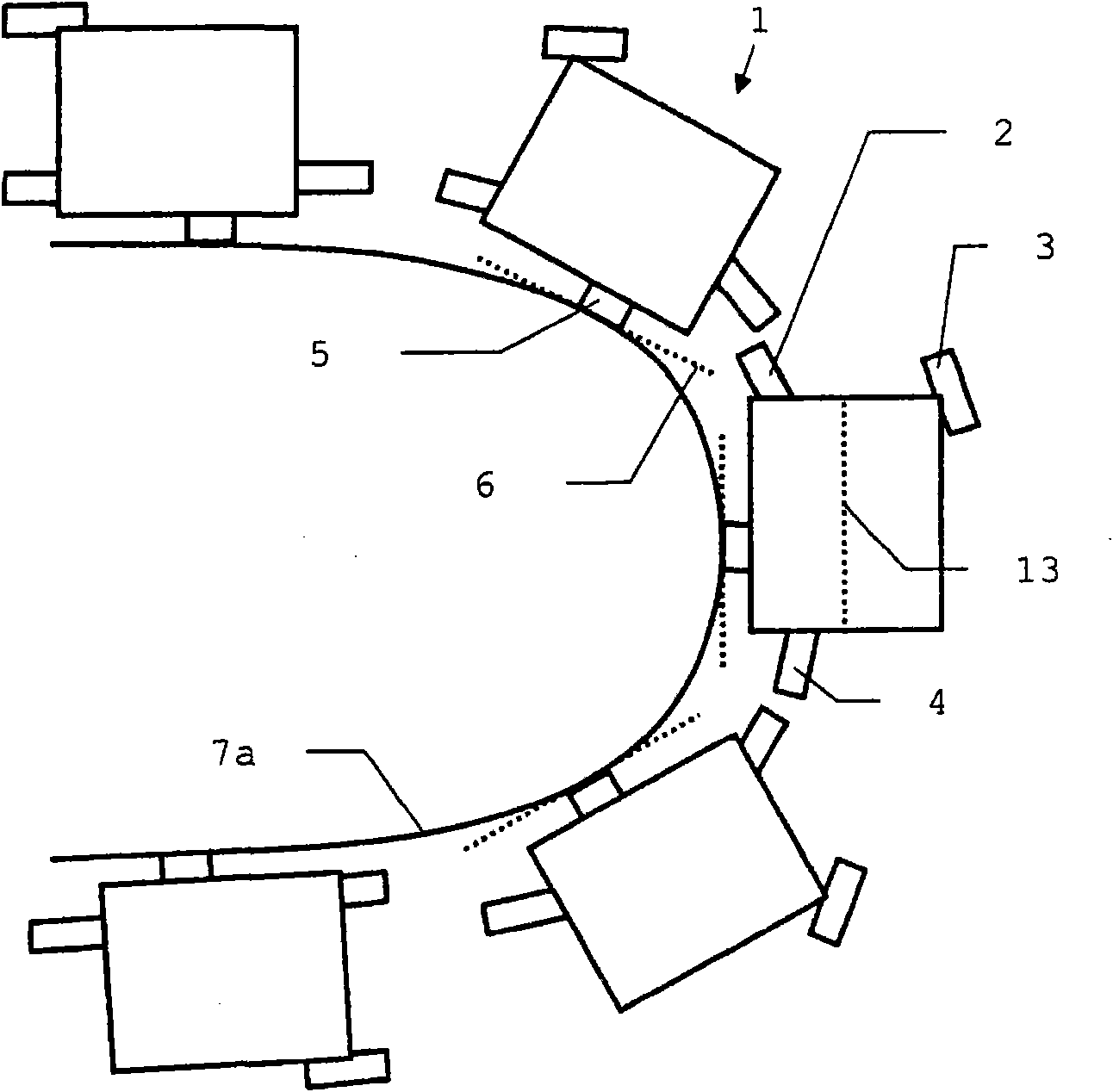

[0024] exist figure 1 In FIG. 1 , various positions of the prior art mobile construction machine 1 when turning along the predetermined projection line 7a of the structure to be constructed are shown for the purpose of illustration. When driving around a bend, the longitudinal machine axis 13 should be parallel to the tangent 6 of the projection line 7 a at the point of contact of the tool 5 and the projection line 7 a in every position. In order to avoid lateral movement of the tool, when steering the machine's front track drives 2 and 3, it is necessary to steer the rear track drive 4 in the opposite direction.

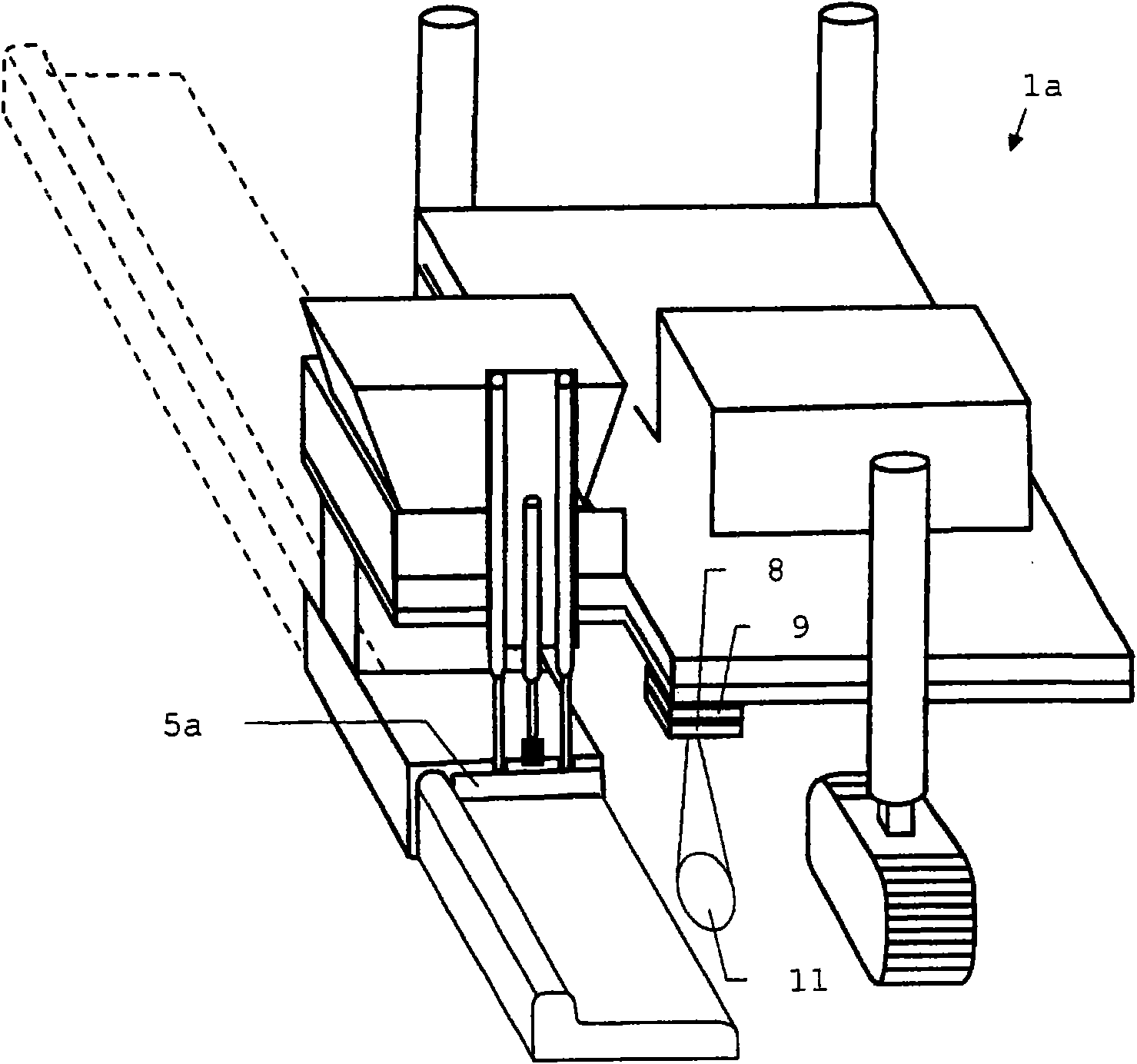

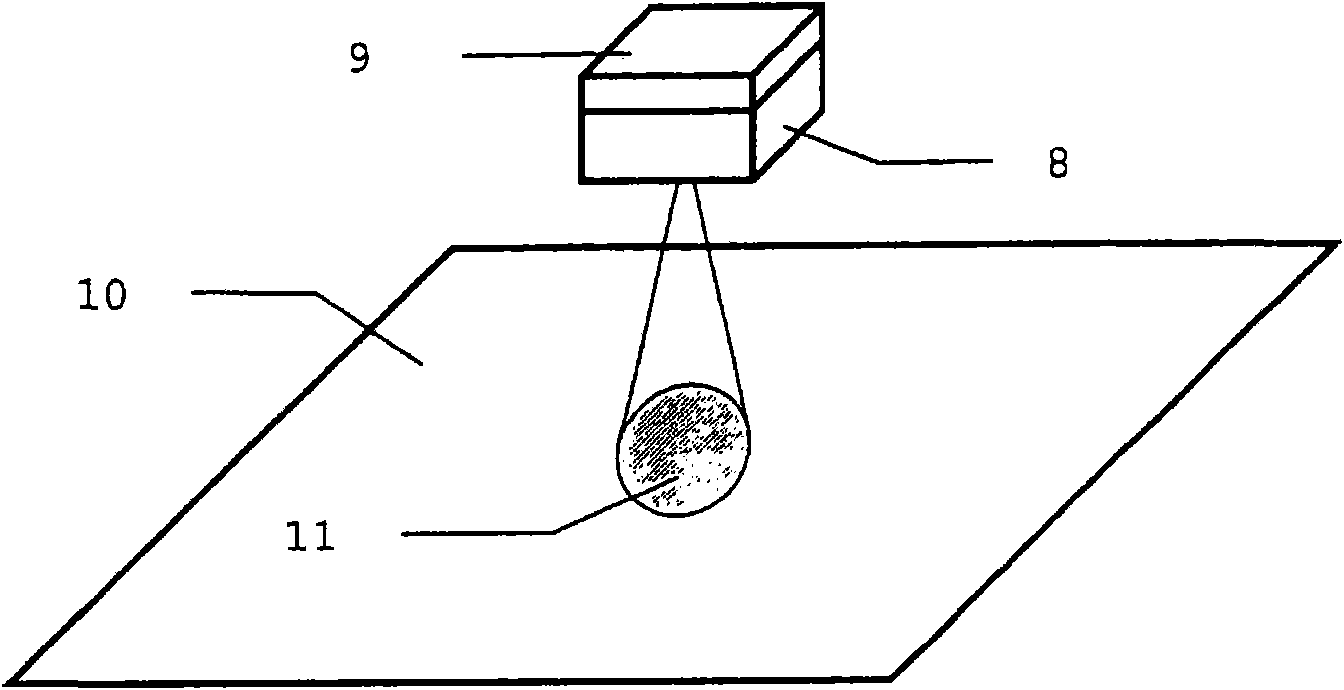

[0025] figure 2 A lateral drift correction device according to the invention is shown with a sensor part 8 and an analysis part 9 mounted under the bottom of the slipform machine 1a adjacent to the construction tool 5a. The sensor part 8 determines the ground condition of the ground part 11 passed by the construction machine and sends this information to the anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com