Multi-pipeline flowing-type oxygenerator

An oxygen concentrator and flow-type technology, applied in the field of medical and health care products and multi-pipe flow oxygen concentrators, can solve the problems of large size, high price, affecting the overall cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific embodiment of the invention will be further described below in conjunction with the accompanying drawings.

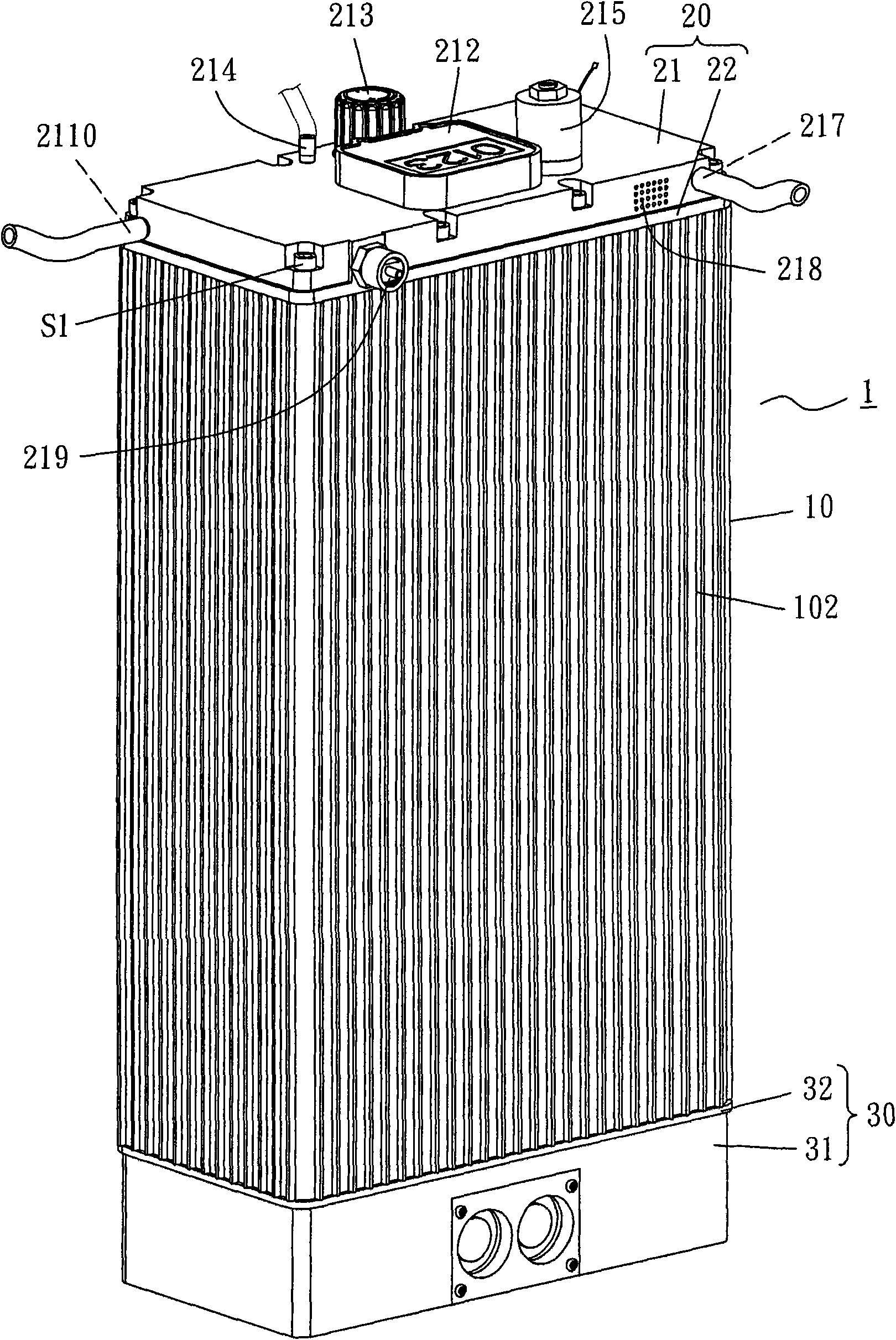

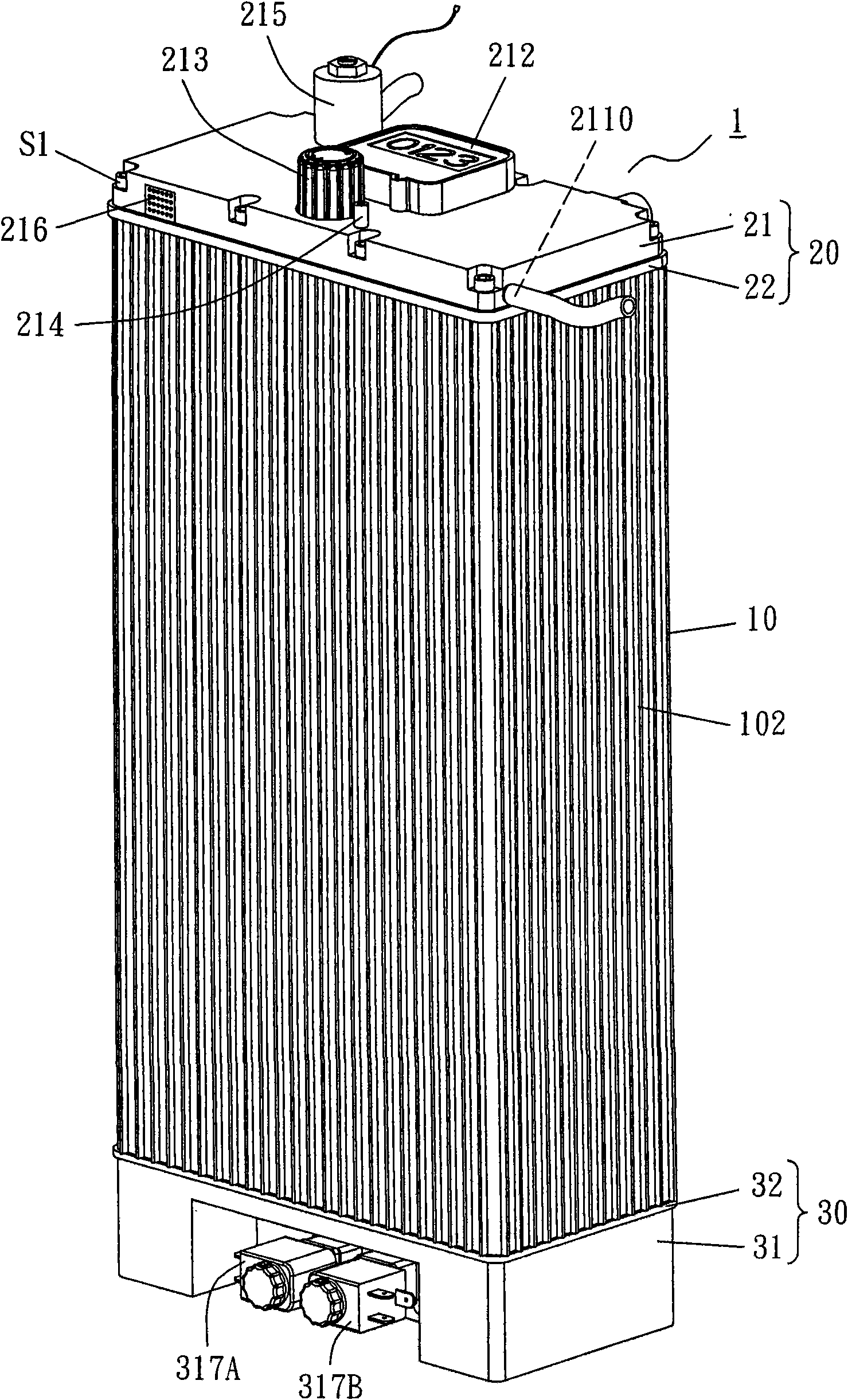

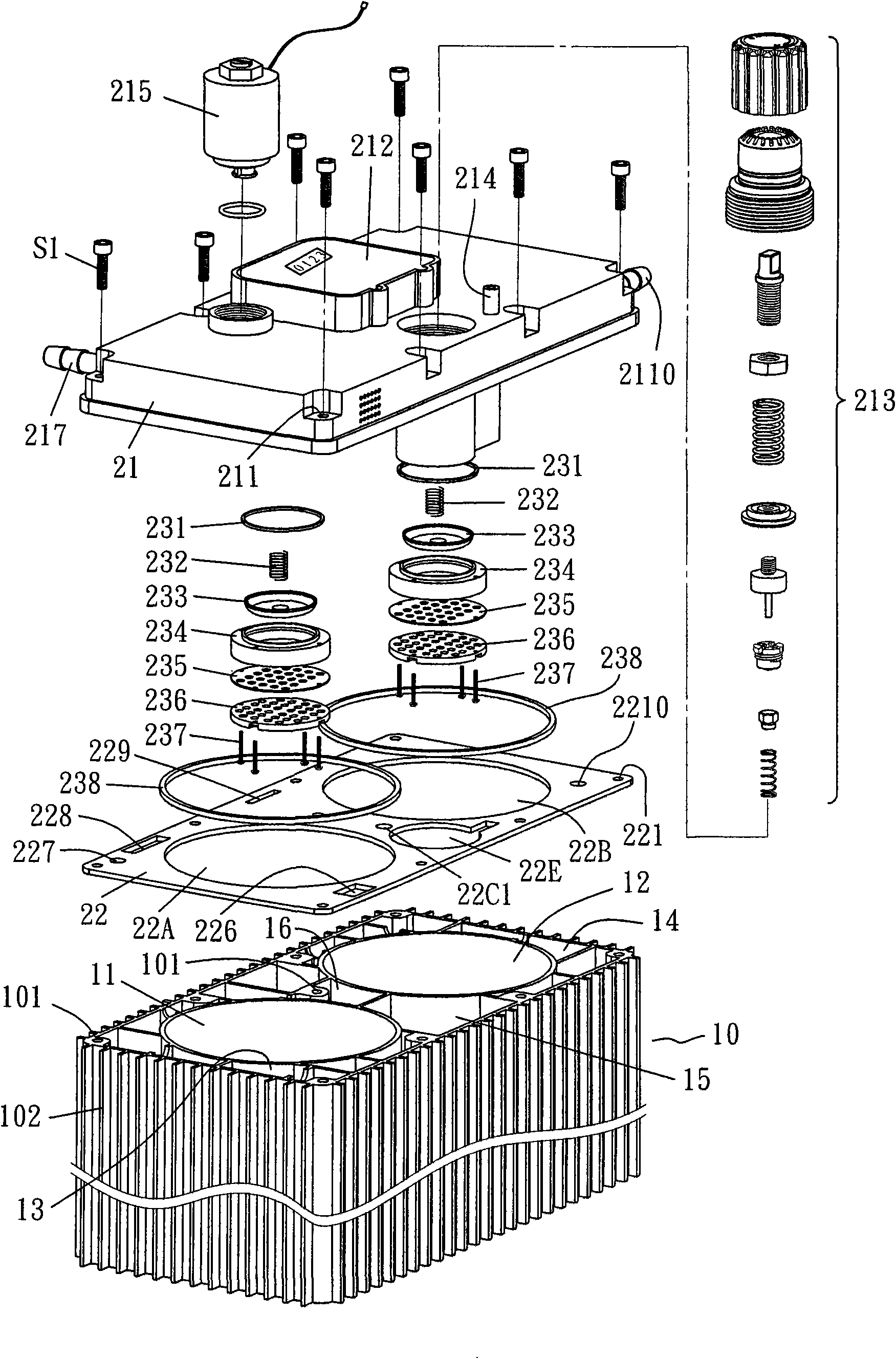

[0058] see figure 1 , 2 As shown, the embodiment of the present invention is an oxygen concentrator 1, which is composed of a body shell 10, a cover set 20 and a base set 30; wherein, the body shell 10 is integrally formed as a top by extrusion It is better to open the bottom and close to the rectangular cube; please refer to image 3 , 4 , 5, viewed from the top and bottom views, the top and bottom of the body shell 10 are provided with a number of assembly holes 101 that penetrate up and down on the periphery and in the middle, and most of them are formed in a regular arrangement on the outer surface. The heat dissipation ribs 102 are formed inside to form a large number of connecting rib walls to separate two large storage cylinders 11, 12 on the left and right sides, and there are a group of air flow channels 13, a group of air intake channels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com