Working mode for controlling heating of anti-condensation cream by using humidity sensor on refrigerator

A technology of humidity sensor and working method, which is applied in household refrigeration equipment, lighting and heating equipment, applications, etc., and can solve problems such as single program, non-disclosure, and reduction of energy consumption of refrigerators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In Embodiment 1, the entire humidity range is divided into 10 ranges in equal parts, that is, the entire humidity range is divided into a humidity range every 10%, and each humidity range in this division is defined as a humidity level G, and The working mode of the heating device under the corresponding grade G is stipulated. The working mode of the heating device here refers to the time ratio T of the heating device on and off, that is, the ratio of the heating device on and off time, which is specified in this embodiment The initial value of T is T0=1, and the on-off time ratio T of a grade G of the above-mentioned division and its corresponding heating device is, T=T0×(1+G), so when the humidity parameter in the air detected by the humidity sensor And after determining the humidity range in which the humidity parameter is located, the time ratio T of starting and stopping the heating device corresponding to the humidity parameter can be obtained. For example, when t...

Embodiment 2

[0024] In Example 2, the entire humidity range is divided into 5 humidity ranges in equal parts, that is, a humidity range is divided every 20%, each humidity range corresponds to a humidity level G, and the corresponding humidity is also specified. The working mode of the heating device under the level, which also refers to the time ratio T of the heating device on and off. In addition, the relational expression between the grade G and its corresponding time ratio T in this embodiment is the same as the relational expression in the first embodiment. In this way, although the number of divided humidity ranges in embodiment 2 is relatively small, in fact, it can more effectively ensure that the refrigerator does not produce condensation in each humidity range, because compared with the same humidity range in embodiment 1 This is due to the relatively high on-off ratio of the heating device used in the humidity range.

[0025] In the above two embodiments, the humidity range is...

Embodiment 3

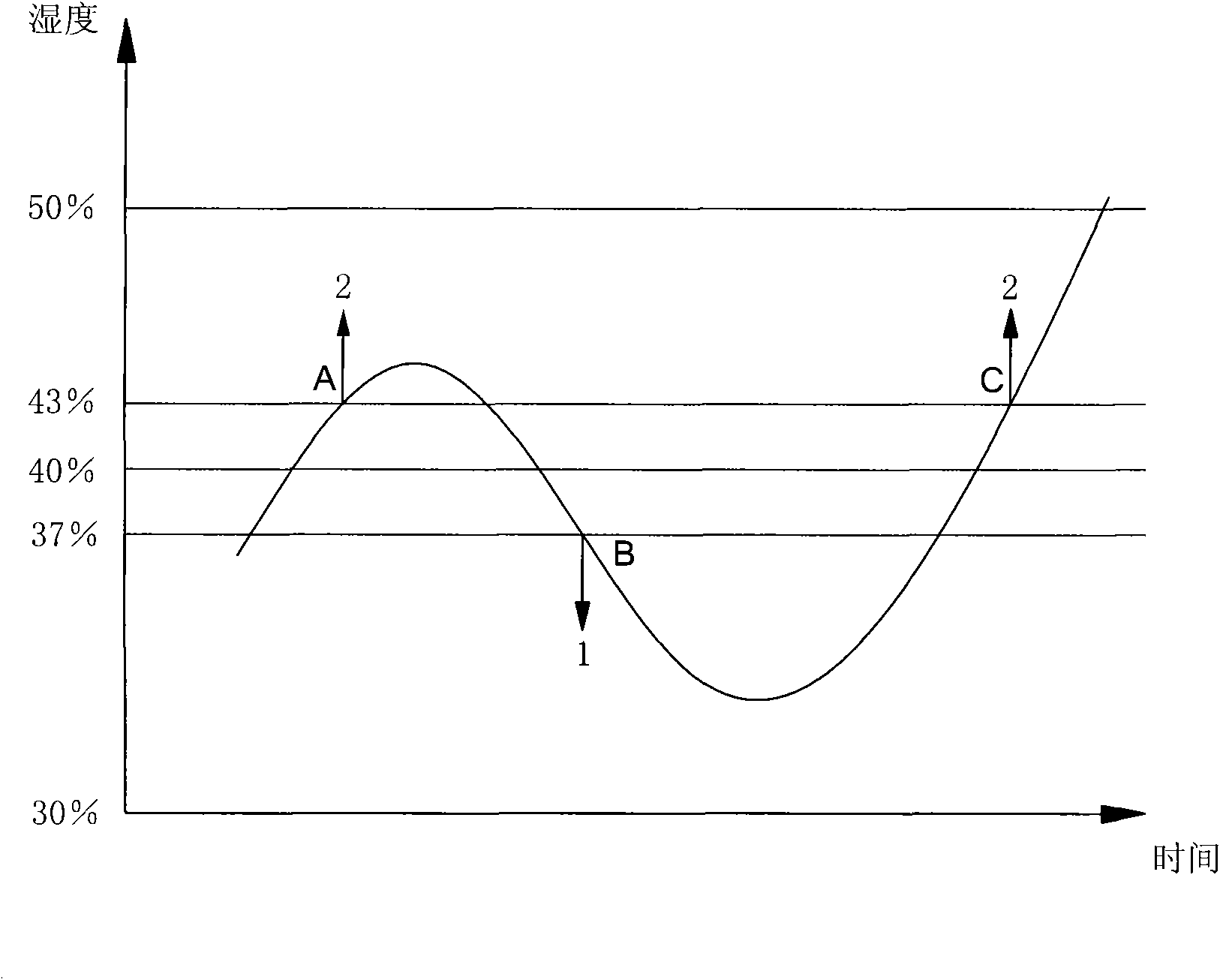

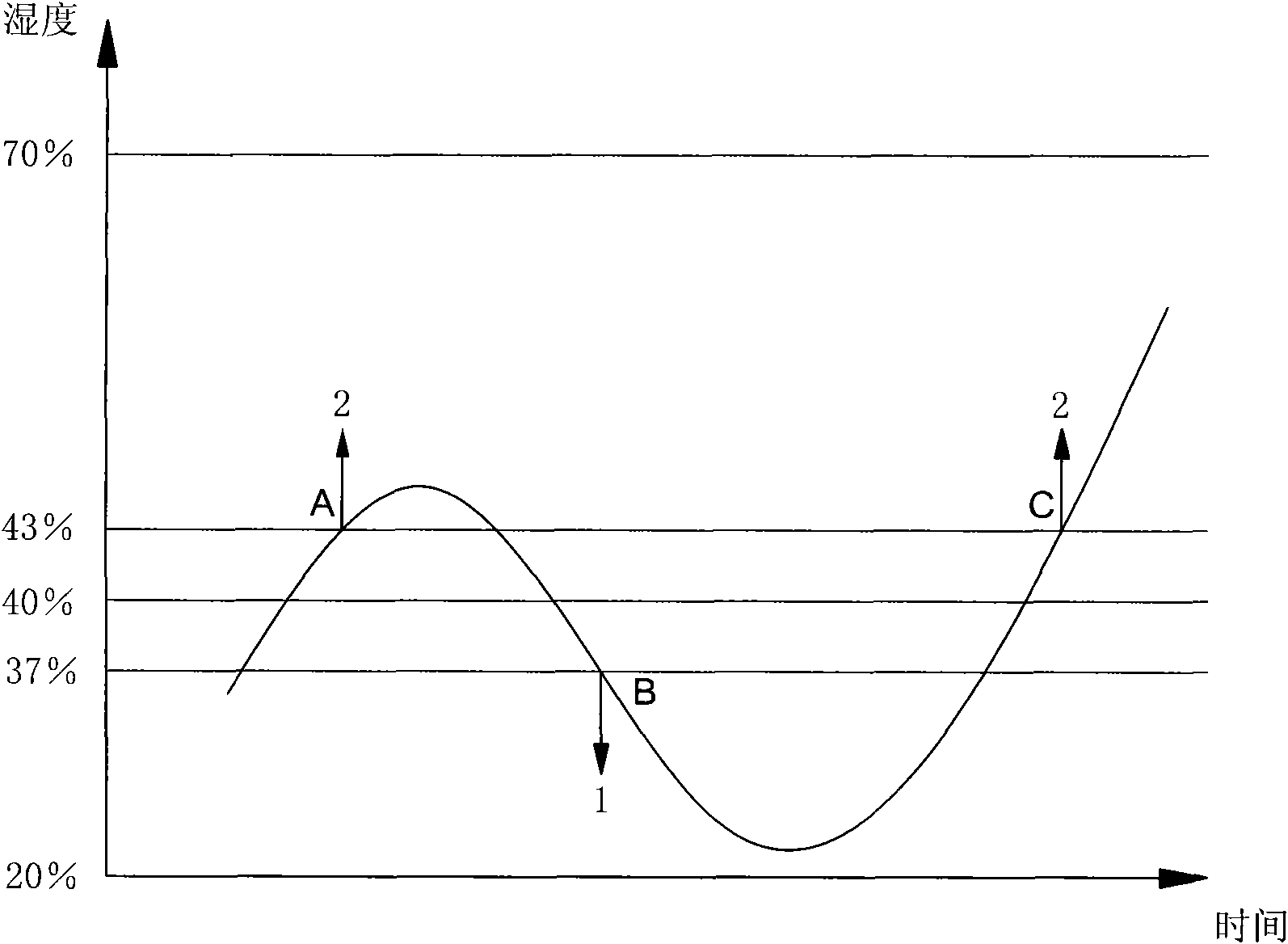

[0026] In Embodiment 3, after the humidity range is divided according to the method in Embodiment 1, a buffer zone is set between adjacent humidity ranges to overcome the humidity error sensed by the humidity sensor itself. The humidity error of the humidity sensor mentioned here refers to the situation that the accuracy of the humidity sensor itself is not accurate or the ambient humidity is just on the dividing line of the humidity range. The working mode keeps changing, which seriously affects the heating effect of the anti-condensation heating device and the service life of the control module. However, after the buffer is set, the above situation can be effectively prevented from happening.

[0027] In Embodiment 1 of the present invention, the humidity of the air in the environment has been preliminarily divided into 10 humidity ranges. In Embodiment 3, there are The humidity area forms a buffer zone, and the buffer zone is equally divided in the adjacent humidity range....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com