Gas combustion type knock tool

A technology for driving tools and gas, applied in the direction of nailing tools, manufacturing tools, etc., can solve problems such as feed failure, hammering piston can not return, deformation of connecting materials, etc., to prevent return failure, eliminate friction, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

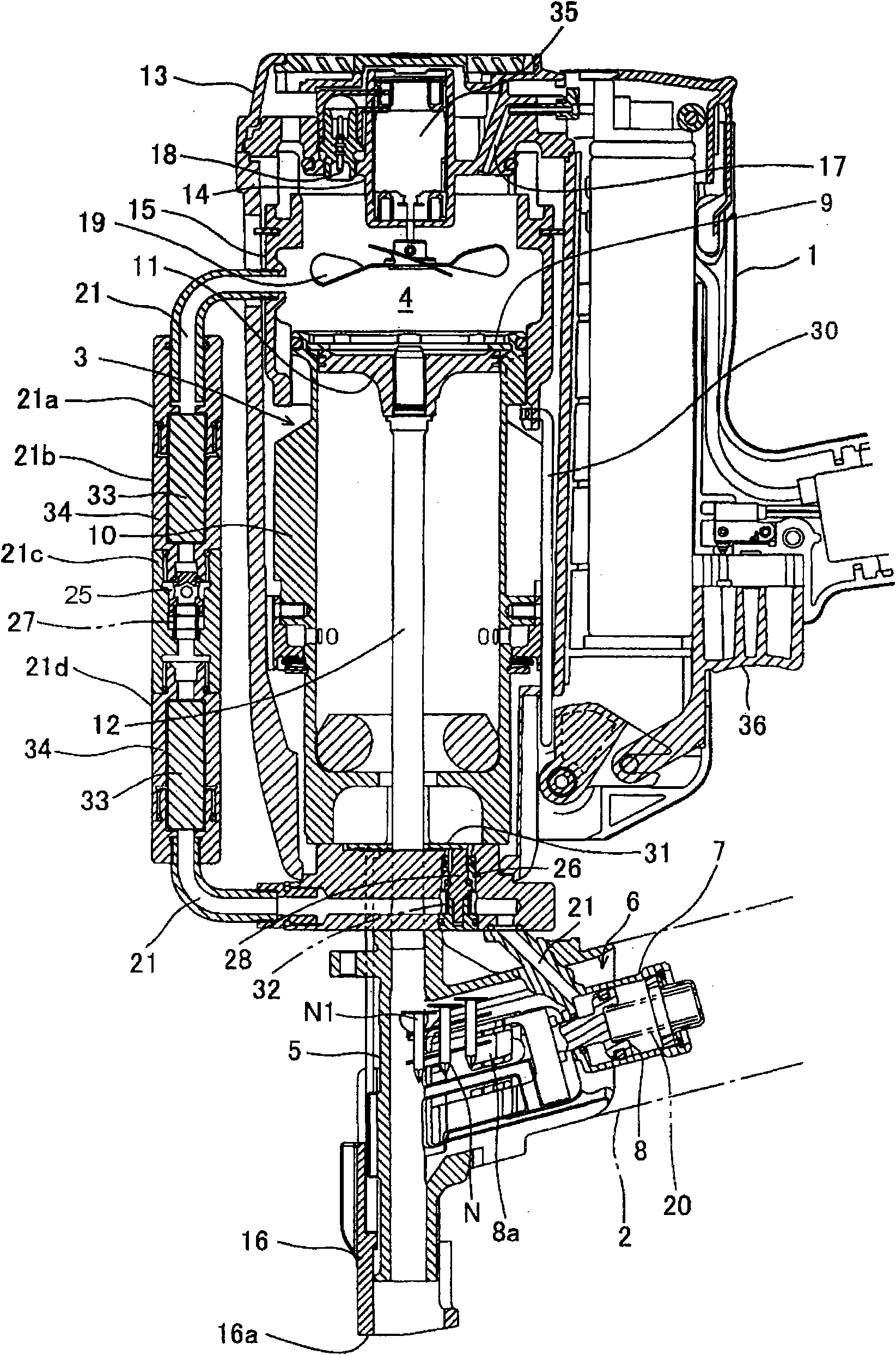

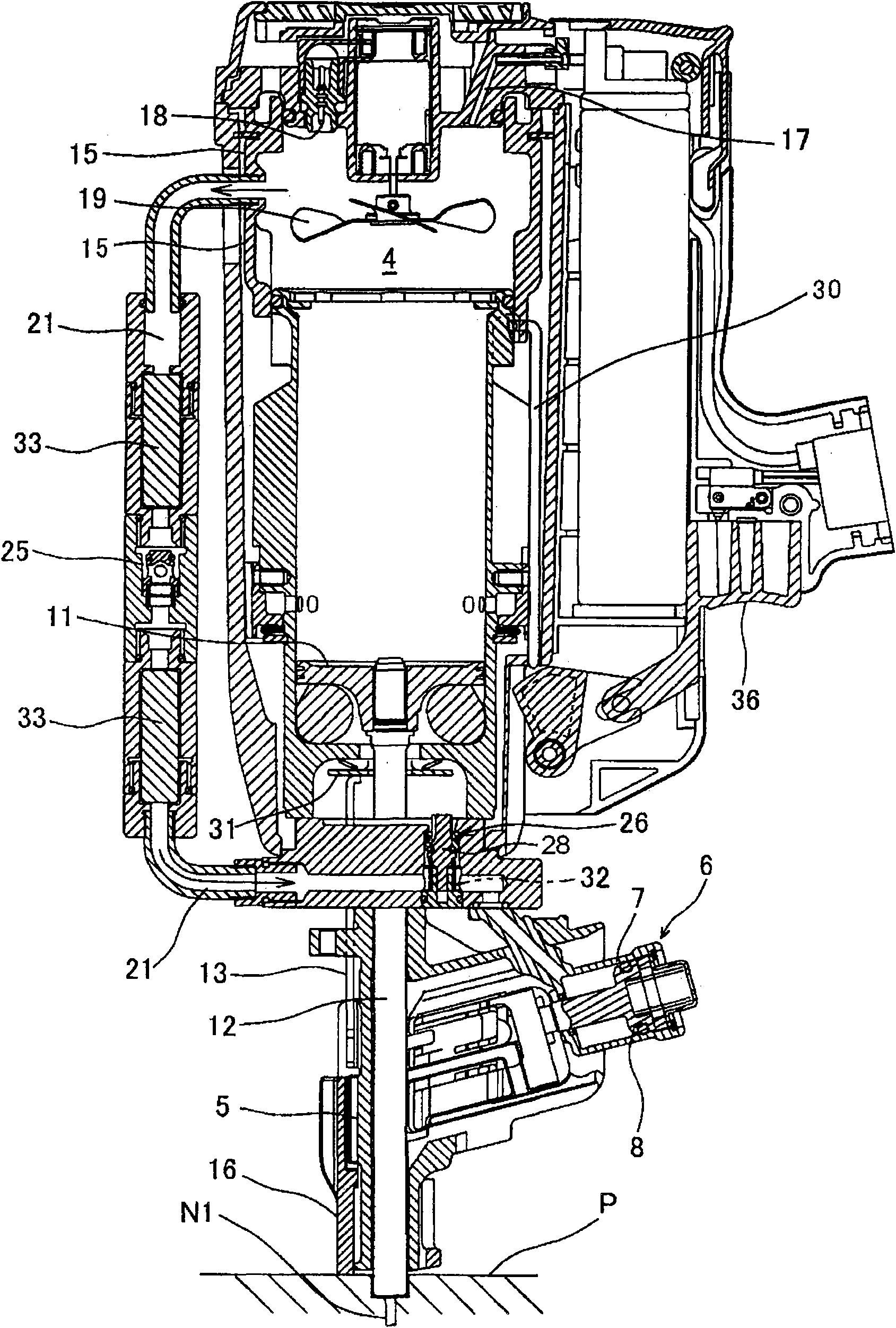

[0014] figure 1 Among them, reference numeral 1 represents the body of the gas combustion type nail driving device. The body 1 is provided in a continuous manner with a handle (not shown) and a nail magazine 2, but also with a hammering piston / cylinder mechanism 3, a combustion chamber 4, a nose portion 5 and a feed piston / cylinder for feeding the nails Institution 6.

[0015] The hammer piston / cylinder mechanism 3 includes a hammer piston 11 in a hammer cylinder 10 in a slidable manner, and is integrally connected with a driver 12 below the hammer piston 11 . It should be noted that the C-shaped snap ring 9 limits the upward movement of the hammer piston 11 .

[0016] The combustion chamber 4 is formed by the upper end face of the hammering piston 11; the upper wall 14 (cylinder head) formed in the upper casing 13; and the annular movable sleeve 15 between the aforementioned two elements. like figure 1 As shown, the device is constructed to pass as figure 2 Moving the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com