Lighting device and display device

一种照明装置、照明区域的技术,应用在照明装置、照明和加热设备、照明系统的光导等方向,能够解决显示器薄型化障碍等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

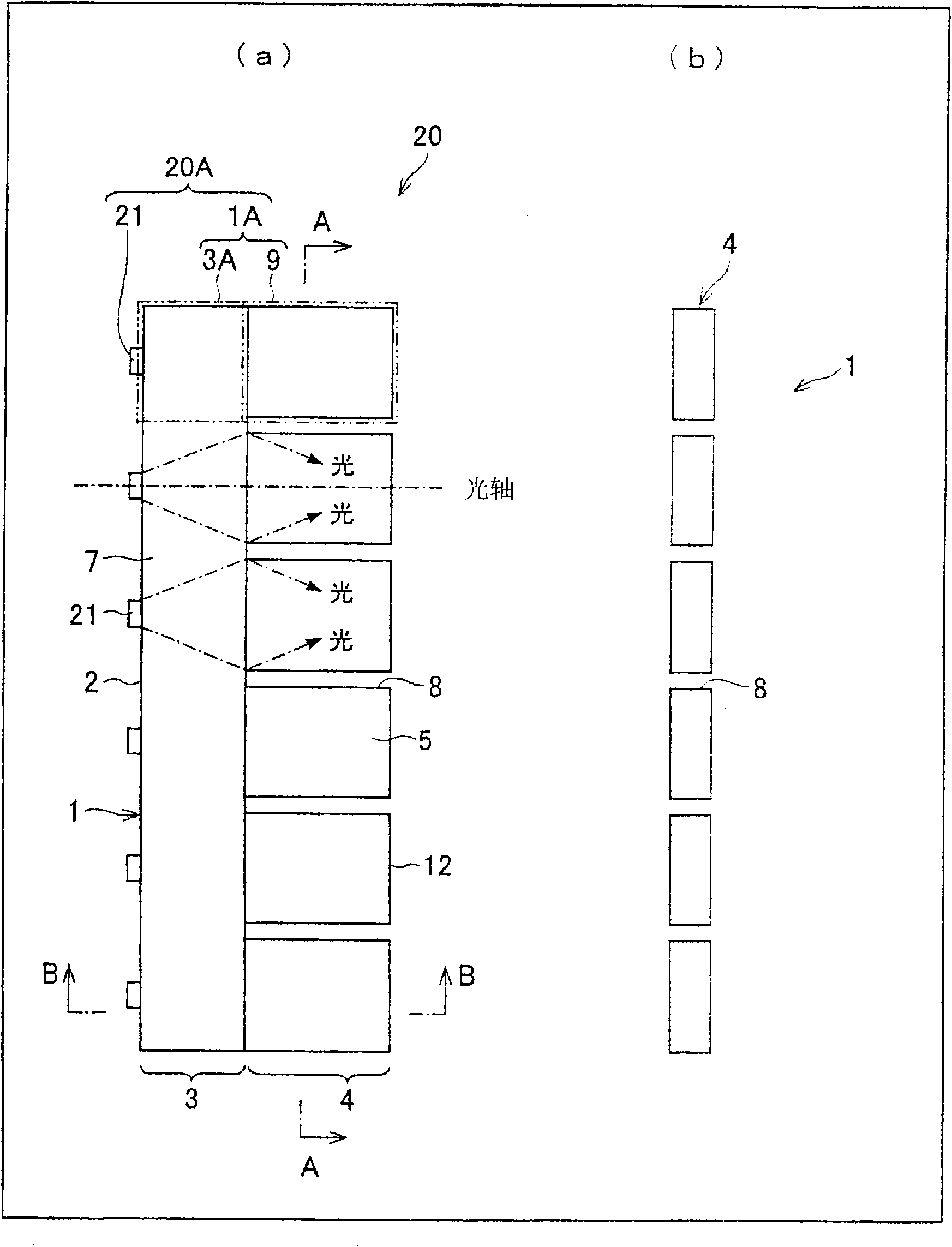

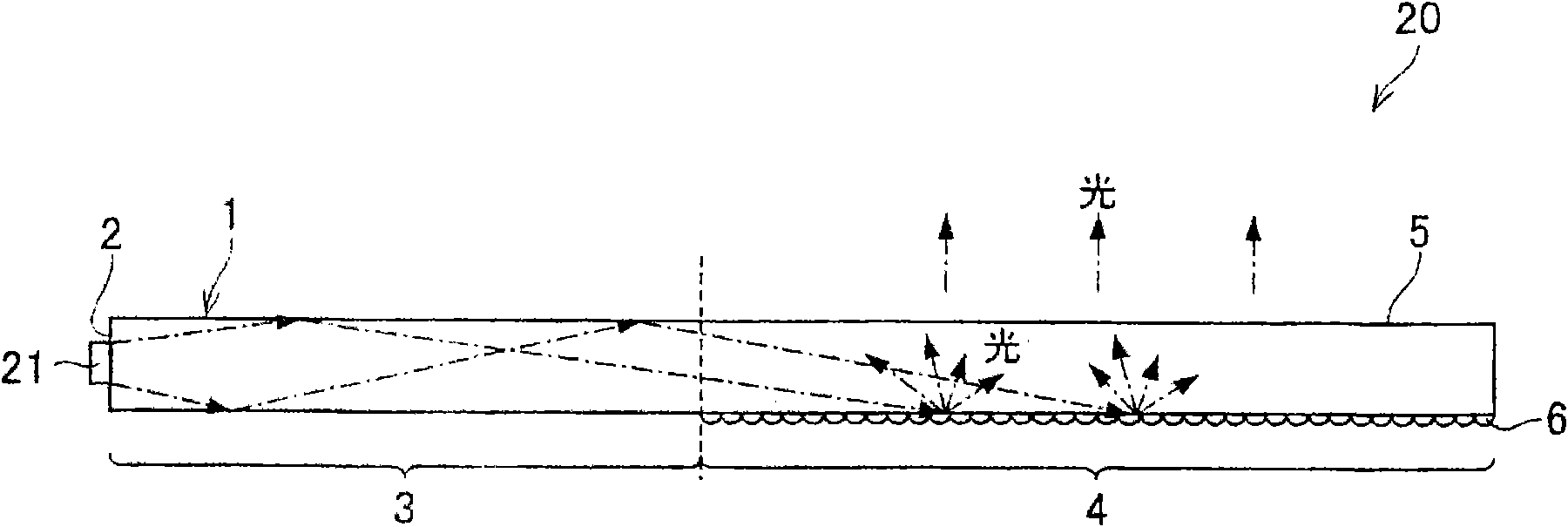

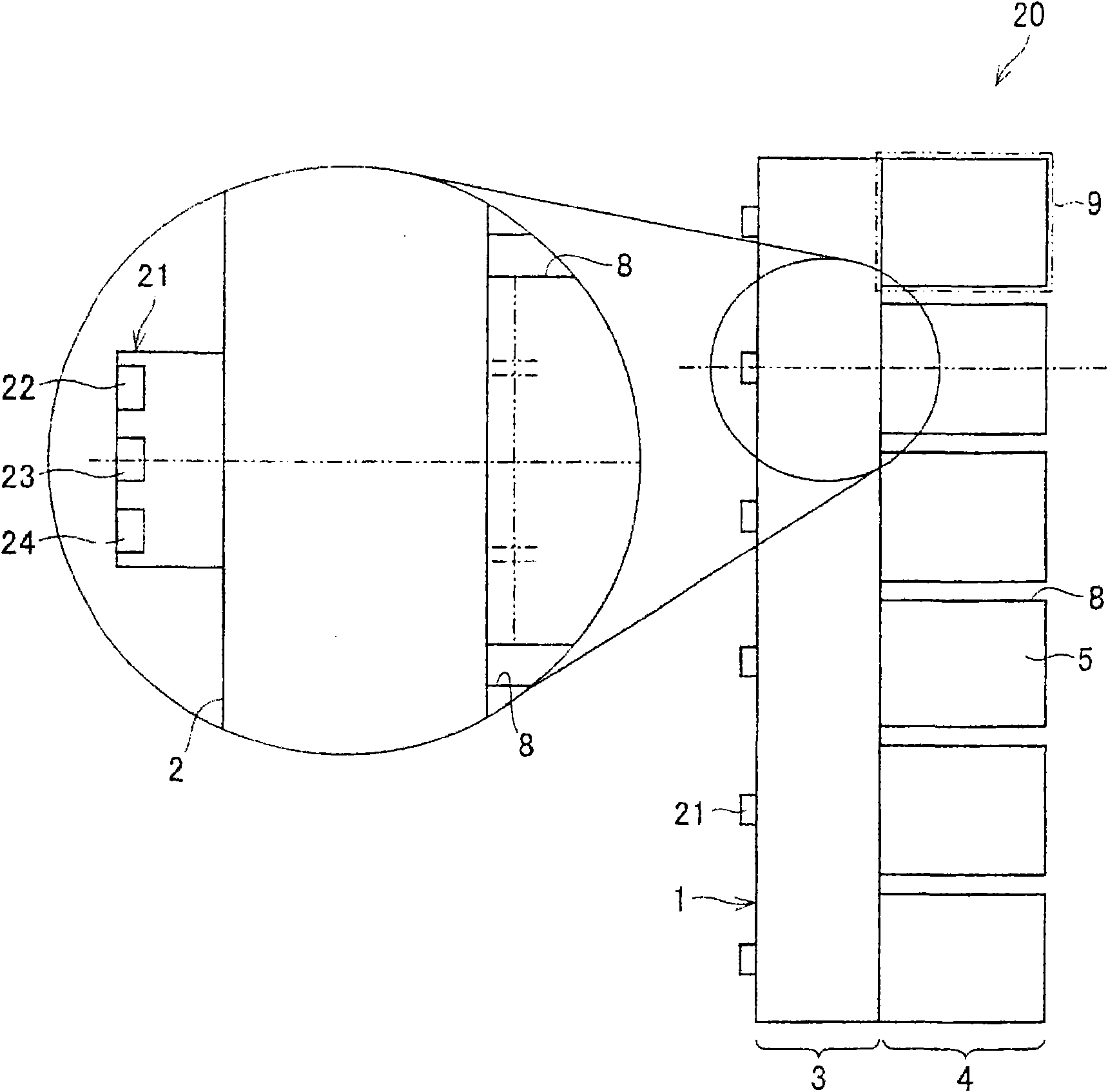

[0120] according to figure 1 (a), (b) to Figure 14 as well as Figure 32 , Figure 36 to Figure 38 One embodiment of the present invention will be described as follows.

[0121] figure 1 (a) is a plan view showing a schematic configuration of a light source unit according to the present embodiment, figure 1 (b) is along figure 1 (a) A-A line sectional view of the light guide plate of the light source unit shown. figure 2 is along figure 1 (a) A cross-sectional view taken along the line B-B of the light source unit.

[0122] Such as figure 1 As shown in (a), the light source unit 20 of this embodiment includes a light guide plate 1 (light guide body) and a plurality of light sources 21 (point light sources) provided on one end surface of the light guide plate 1 .

[0123] The light source unit 20 is a side-light type light source unit (surface light source unit) provided with a light source 21 and emitting (surface emission) light incident from one end surface of the...

Embodiment approach 2

[0288] For this embodiment, mainly based on Figure 15 (a) and (b) are explained as follows. In addition, in this embodiment, the point which differs from Embodiment 1 mentioned above is demonstrated, and the structural element which has the same function as Embodiment 1 mentioned above is attached|subjected to the same code|symbol, and the description is abbreviate|omitted.

[0289] Figure 15 (a) is a plan view showing a schematic configuration of the light source unit 20 of this embodiment, Figure 15 (b) is along Figure 15 (a) is a sectional view taken along the line D-D of the light guide plate 1 of the light source unit 20 shown.

[0290] In the light source unit 20 of this embodiment, instead of figure 1 The slit portion 8 described in (a) and (b) is provided with a groove portion 13 (groove). That is, the light guide plate 1 of the present embodiment has a structure in which the illumination area 4 is divided into a plurality of light emitting sections 9 by repla...

Embodiment approach 3

[0303] For this embodiment, mainly based on Figure 16 (a), (b) and Figure 17 (a) and (b) are explained as follows. In this embodiment, differences from Embodiments 1 and 2 described above will be described, and constituent elements having the same functions as Embodiments 1 and 2 described above will be given the same reference numerals, and descriptions thereof will be omitted.

[0304] Figure 16 is a plan view showing a schematic configuration of the light source unit 20 of the present embodiment, Figure 16 (b) is Figure 16 (a) is a cross-sectional view taken along line E-E of the light guide plate 1 of the light source unit 20 shown. in addition, Figure 17 (a) is a plan view showing a schematic configuration of another light source unit 20 according to the present embodiment, Figure 17 (b) is Figure 17 (a) A cross-sectional view taken along the line F-F of the light guide plate 1 of the light source unit 20 shown.

[0305] The light source unit 20 of this em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com