A metal wire cutting and packing machine with lighting effect

A metal wire and laser cutting machine technology, applied in lighting applications, lighting device parts, lighting devices and other directions, can solve the problems of difficult to accurately control the cutting length, large storage area, difficult to compress and bundle, etc., to achieve automation The effect of production and packaging is neat and tidy, and the production efficiency is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

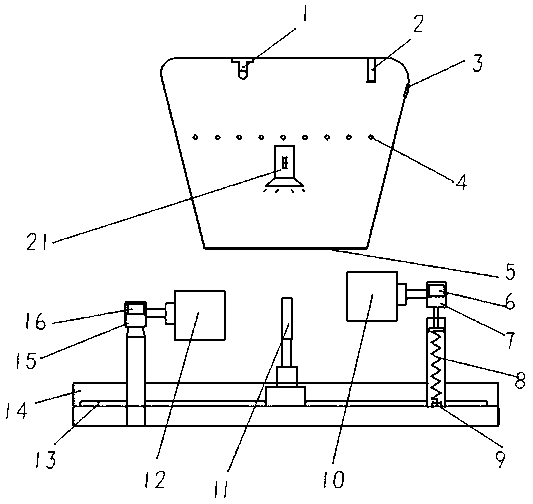

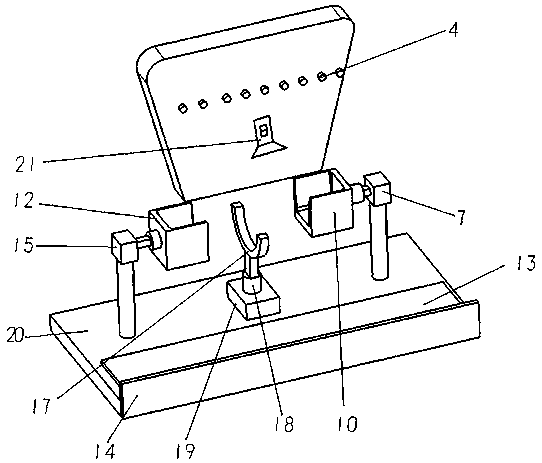

[0022] like figure 1As shown, a wire cutting baler with lighting effect includes a feeding device, a cutting device, a tally device, a baling device 11, and a conveying device; the feeding device is set as an inverted trapezoidal hollow box body, and the The feeding device includes a feeding port 3, a material limiting column 4 and a discharging port 5; the feeding port 3 is arranged above the side of the inverted trapezoidal hollow box body; the material limiting column 4 is arranged on the inverted trapezoidal hollow box body The middle position and runs through the box body; the discharge port 5 is set at the lower end of the inverted trapezoidal hollow box body; the cutting device includes a laser cutting machine and a photoelectric induction device 1, and the cutting hole 2 on the laser cutting machine is provided. on the inner side of the top of the inverted trapezoidal hollow box; the photoelectric sensing device 1 identifies the position of the wire and controls the la...

Embodiment 2

[0025] The second embodiment is basically the same as the first embodiment in structure and principle. The difference is that the material limiting column 4 is replaced with a folding spring stopper, which not only can realize the function of the material limiting column 4, but also has a simpler structure and principle and is convenient to operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com