Bar code locating S/R machine

A stacker and bar code technology is applied in the field of electrical control devices for stacking and handling equipment in warehousing and logistics automated three-dimensional warehouses. and other problems, to achieve the effect of improving positioning accuracy and counting reliability, improving application occasions, and smooth starting and braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

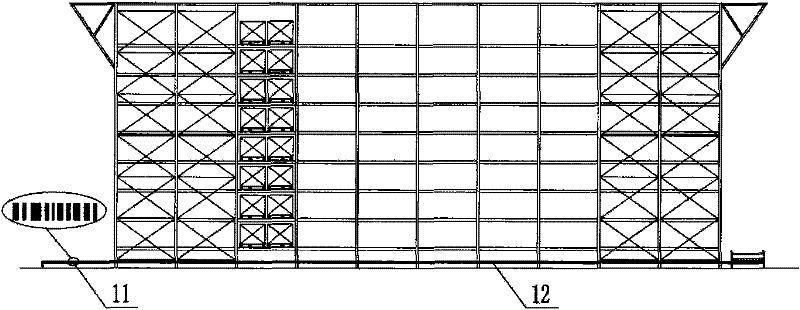

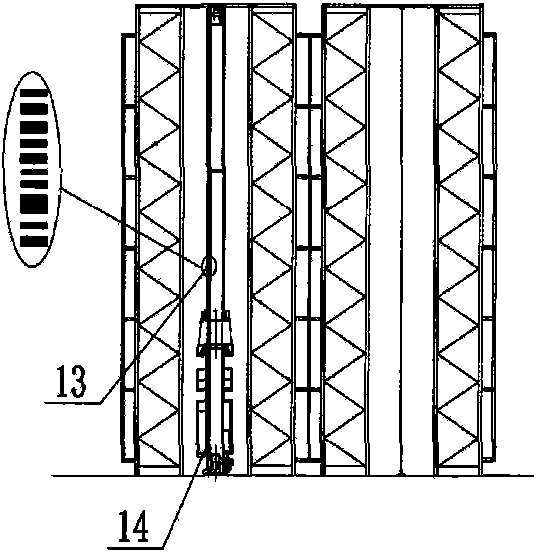

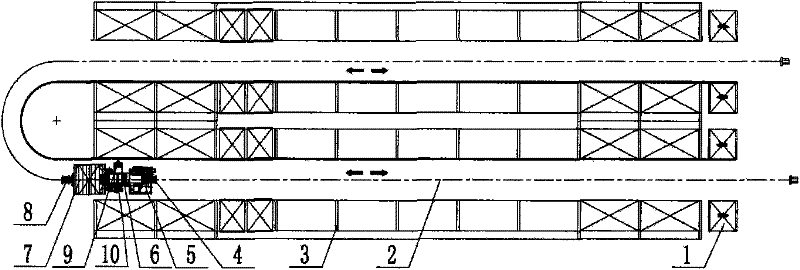

[0014] like Figure 1A , Figure 1B and Figure 1C As shown, it is a schematic diagram of the structure of the automated three-dimensional warehouse, including the inbound and outbound cargo platform 1, the sky and ground rail 2, the shelf 3 and the stacker 4. Rows of shelves 3 are arranged in the automated three-dimensional warehouse, each row of three-dimensional warehouse shelves 3 is provided with a cargo box, and ground rails 2 are arranged between every two rows of three-dimensional warehouse shelves 3, and the entrance and exit of the ground rails 2 There is an inbound and outbound cargo platform 1 at the end, and a stacker 4 that can travel back and forth on the ground rail 2 .

[0015] combine Figure 1A to Figure 1C and figure 2 To illustrate a barcode positioning stacker provided by the present invention, it includes a lower beam 8, an electric control cabinet 5 and a column 6 are arranged on the lower beam 8, a PLC is arranged in the electric control cabinet 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com