Pit-type garbage compressor

A garbage compressor and pit-type technology, which is applied in the direction of garbage transmission, garbage collection, loading/unloading, etc., can solve the problems of poor safety, low degree of automation, and inconvenient transfer, so as to reduce the odor of garbage and the volatilization of harmful gases , reduce the time of dumping garbage, and avoid the effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

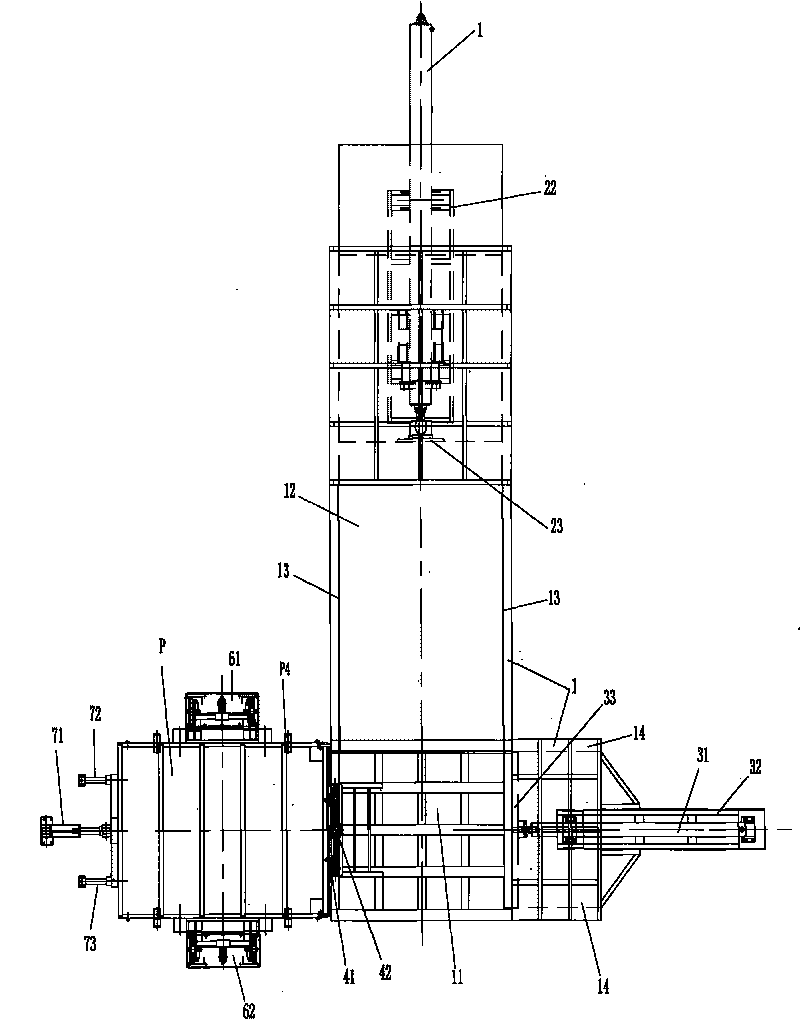

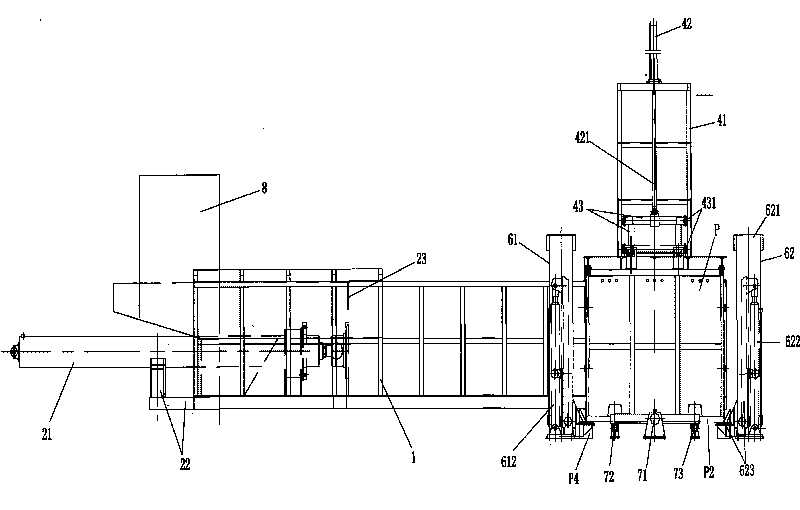

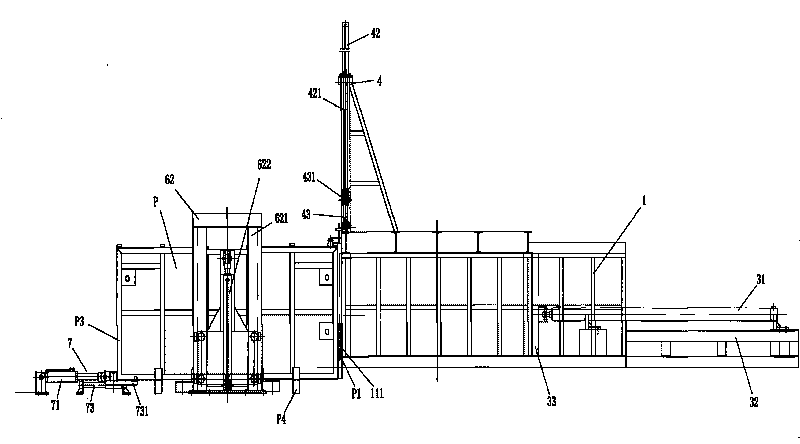

[0027] see Figure 1~3 , with L-shaped frame 1, compression chamber 11, compression cylinder 21, compression cylinder seat 22, compression cylinder 22, compression plate 23, ejection cylinder 31, ejection cylinder seat 32, ejection plate 33, brake lifting frame 4, transfer box P, suitcase frame, transfer box push-pull mechanism 7, hydraulic control device and circuit control device.

[0028]Frame 1 is installed in the pit under the prefabricated ground (pit is not drawn), and frame 1 is the frame that the section bars such as angle steel are welded. The frame 1 is provided with a feed inlet 12 (constituted by the bottom and side baffles of the frame 1), and the compression chamber 11 (consisted of by the bottom, side and top baffles of the frame 1) is provided with In the right-angle area of the frame 1 , a compression cylinder 21 is provided at one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com