Multi-level fine choke manifold and automatic control system

A technology of automatic control system and choke manifold, which is applied in the direction of drilling automatic control system, drilling equipment, wellbore/well components, etc., which can solve the problems of choke valve erosion, difficult adjustment accuracy control, and choke valve failure And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

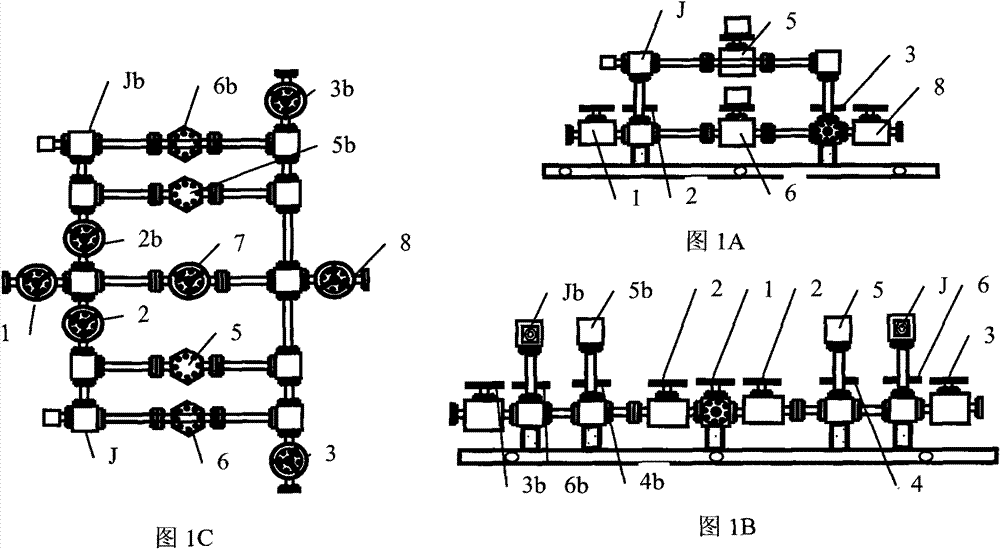

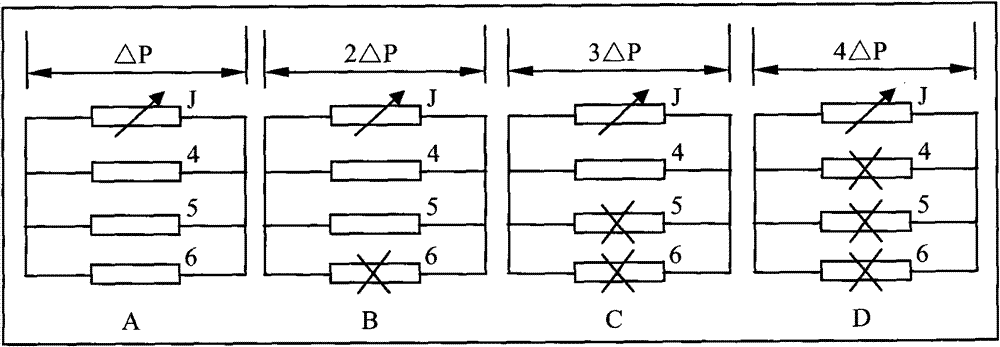

[0016] figure 1 It shows the ground multi-level fine choke manifold system in a best embodiment of the multi-stage fine choke manifold and the automatic control system of the present invention. Among them, 1 is the drilling fluid outlet gate valve returning from the wellhead; 2 is the gate valve at the inlet of the choke manifold; 3 is the gate valve at the outlet of the choke manifold; 4, 5, and 6 are the parallel choke manifold systems for different Three plate valves for pressure level adjustment; J is a throttle valve for fine adjustment under different pressure levels; 7 is a gate valve for the discharge pipeline; 8 is the outlet gate valve for the discharge pipeline.

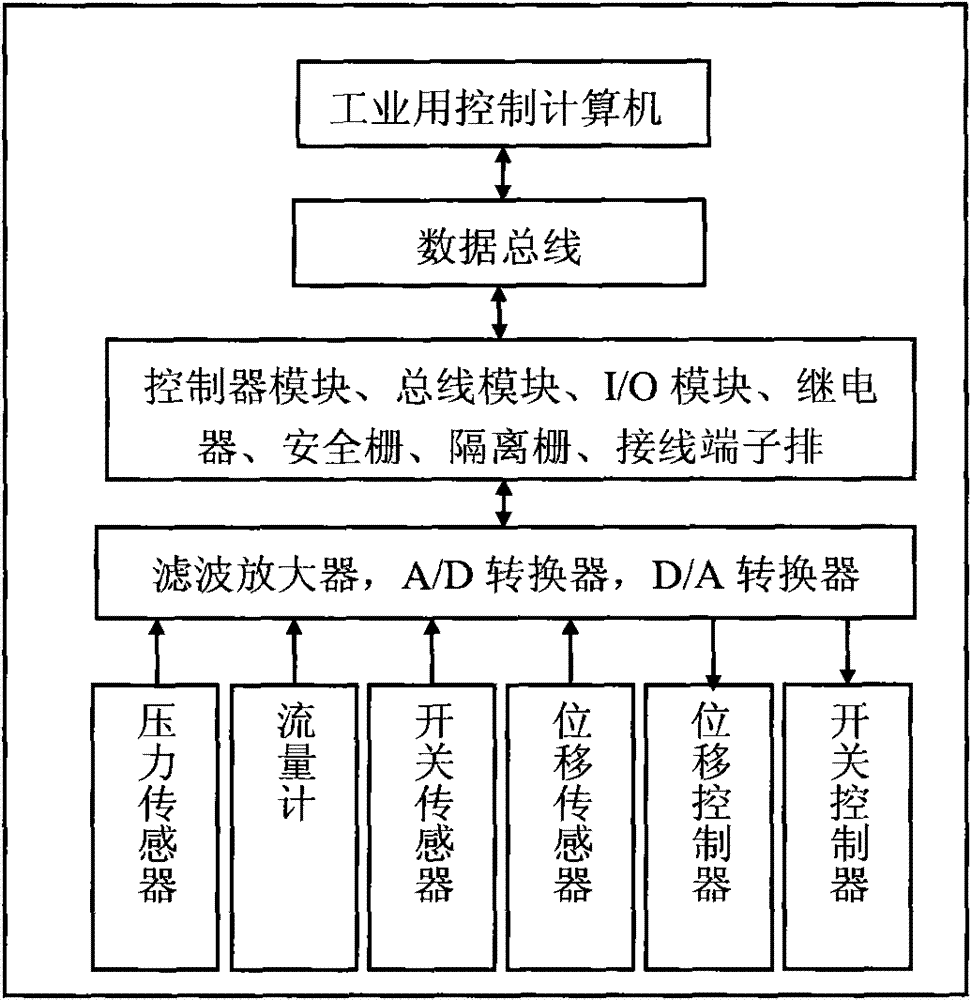

[0017] refer to figure 2 A best embodiment of the automatic control system in the multi-stage fine detail manifold and the automatic control system of the present invention is shown. The system is a three-layer hierarchical control structure, which is divided into bottom-level measurement and control de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com