Method used for detecting concentric circle of industrial part

A detection method and technology of concentric circles, applied in the direction of measuring devices, optical devices, image analysis, etc., can solve problems such as unusable, irregular part images, and increased difficulty in concentric circle detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

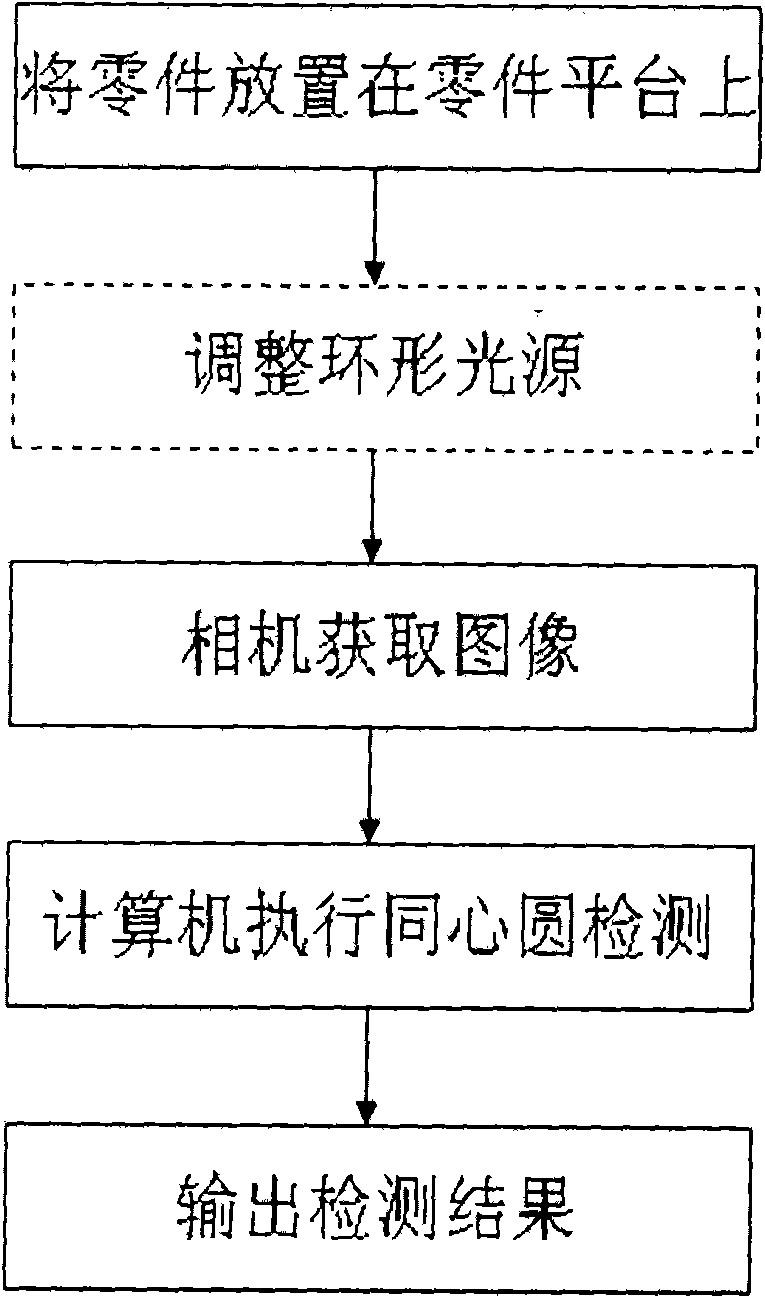

[0053] For the convenience of implementation and reference, the embodiment of the present invention provides a complete actual operation process of concentric circle detection starting from shooting. Among them, in addition to the existing technologies such as shooting methods, the present invention provides a new technical solution for detecting the original image obtained by shooting the concentric circles on the part, which can be automatically realized by computer means. The technical scheme of the present invention is described below in conjunction with accompanying drawing and embodiment:

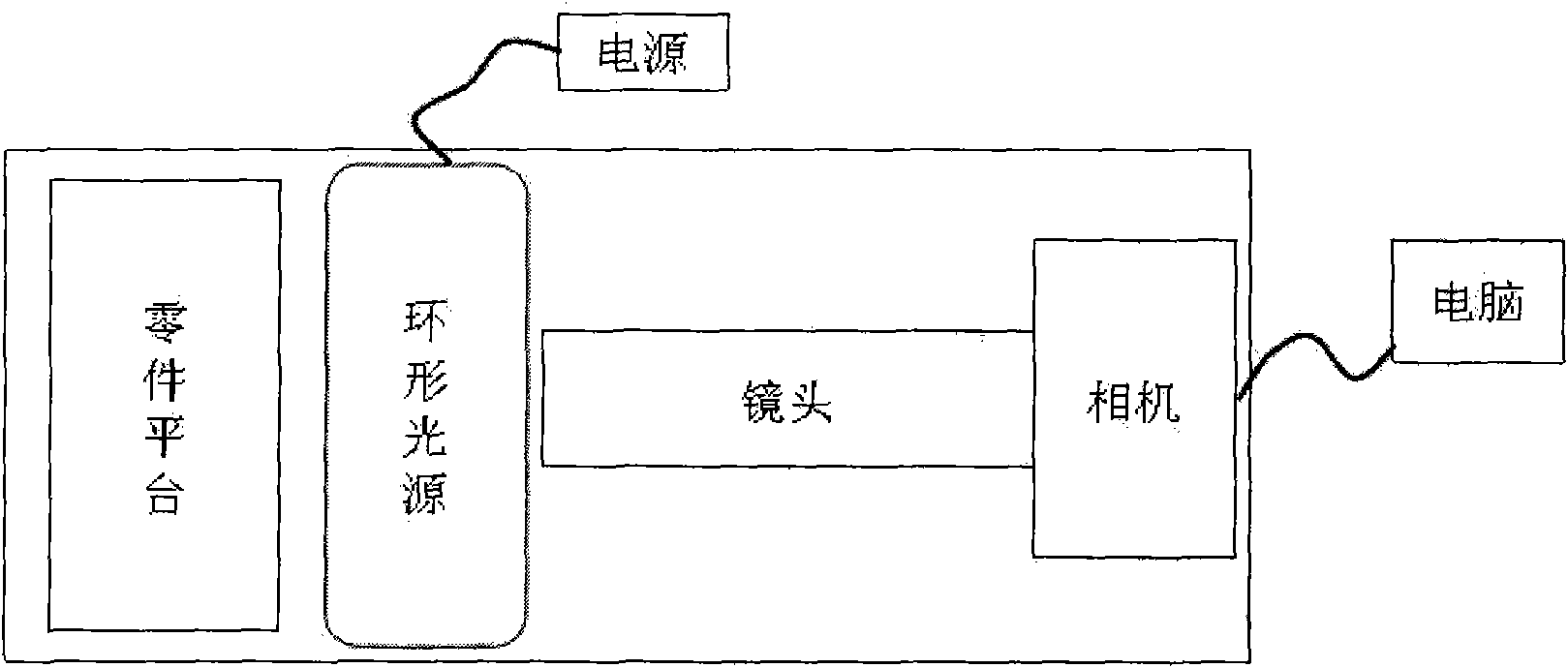

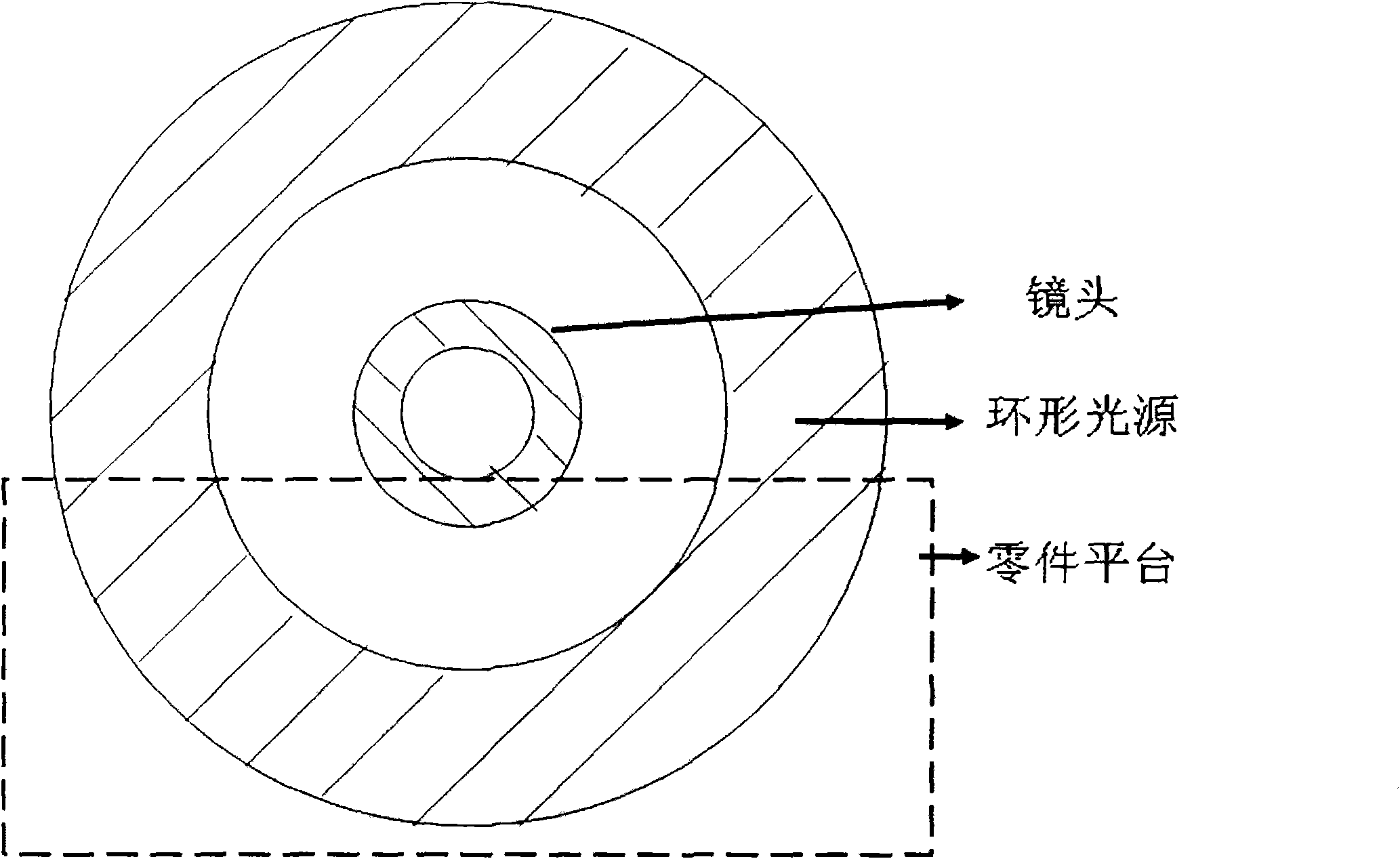

[0054] See attached figure 1 , the concentric circle detection hardware system of embodiment is made up of following parts:

[0055] (1) A camera with a lens. With a USB or 1394 data cable, the data can be transmitted to the computer in real time, the sampling frequency is 15 frames per second or above, and the resolution depends on the situation. It is recommended to use a resolut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com