Mobile anaerobic fermentation container

An anaerobic fermentation and container technology, applied in bioreactor/fermenter combination, special-purpose bioreactor/fermenter, biochemical equipment, etc., can solve interference, suspension, fermentation material spoilage, anaerobic fermentation failure And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

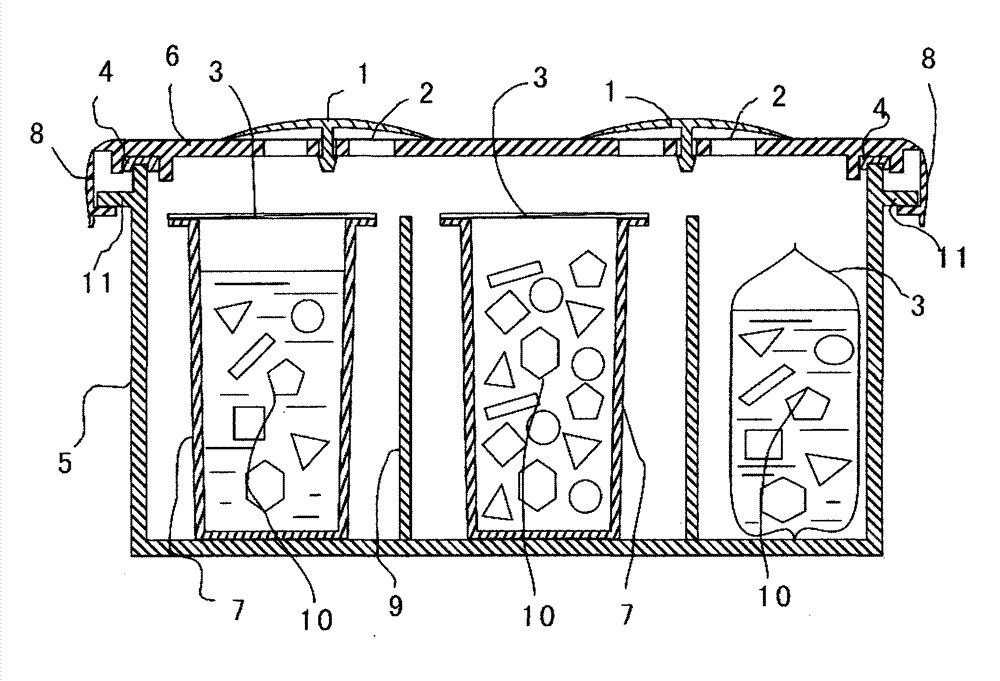

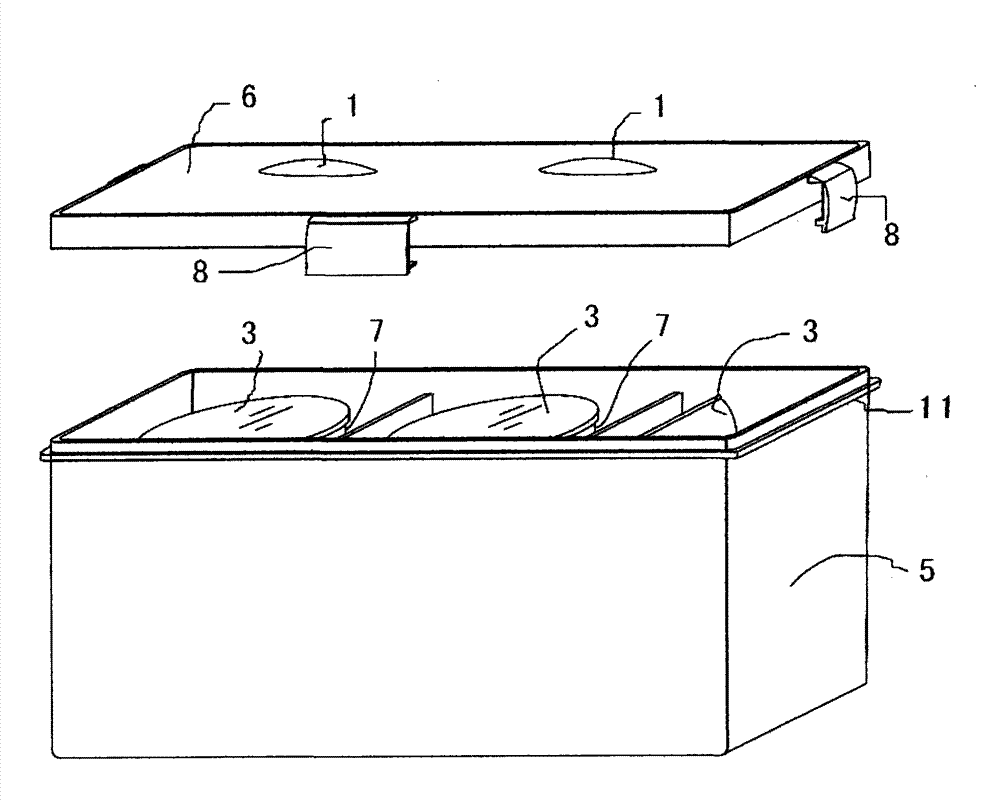

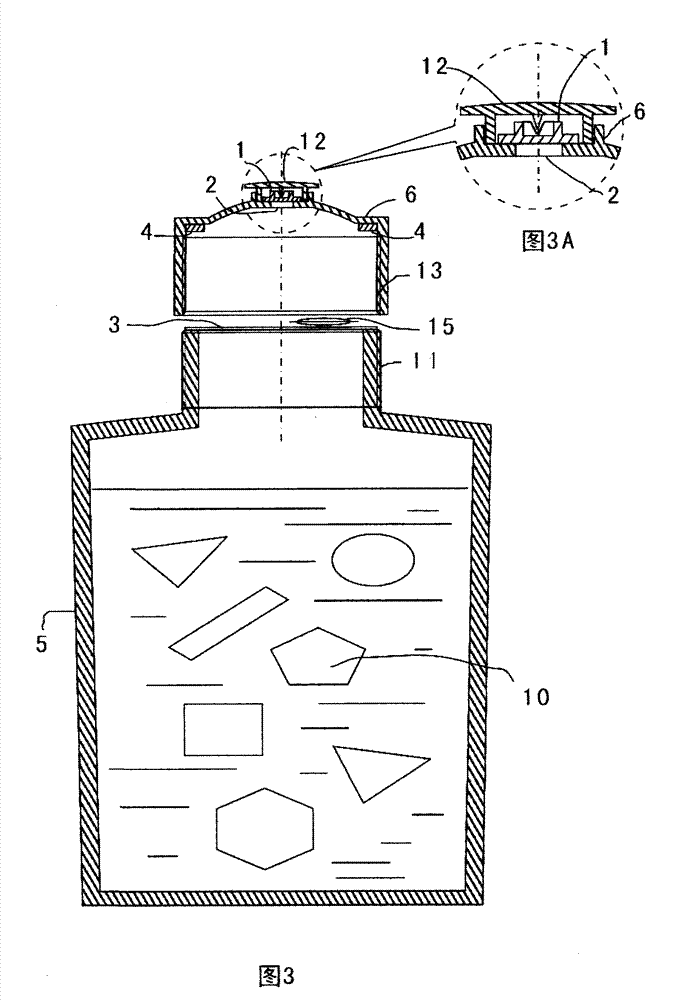

[0017] exist figure 1 , figure 2 In the first embodiment shown, the parallelepiped box-shaped airtight container is composed of a container body 5 with an open top, a sealing gasket 4, and a container cover 6 that cooperates with the container opening. A limited convex edge 11 is set near the mouth of the container, and the middle of the four sides of the container cover 6 has a foldable lock 8. When all the locks 8 are overlapped on the convex edge 11, the sealing gasket 4 is squeezed. A seal is formed between the edge of the container body 5 and the square groove of the container cover 6 . Flipping up all the latches 8 can separate the container cover 6 from the container main body 5 so as to take and place the fermented material therein. The container body 5 and the container cover 6 are formed by injection molding of plastic, preferably polypropylene, and the wall thickness is between 1mm-3mm. The gasket 4 is made of silica gel. Two groups of through holes are arrange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com