Optical film production method

A production method and technology for optical films, which are applied in optics, optical components, filters, etc., to achieve the effect of improving process complexity, reducing requirements and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

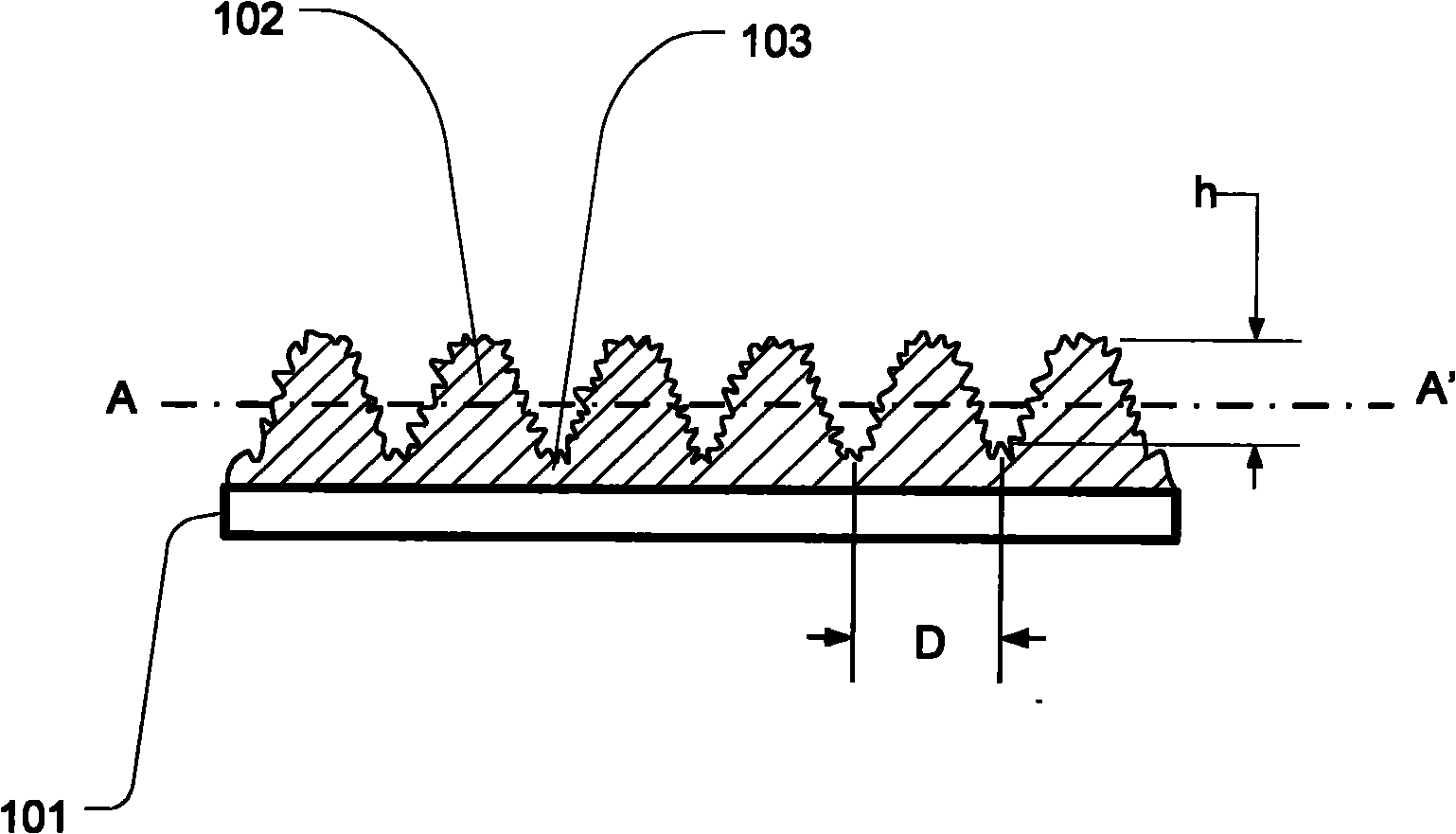

[0030] Depend on figure 1 As known, the optical film 100 includes a base film 101 and a raised microstructure 102 on the surface, and the base film 101 and the raised microstructure 102 are connected by a resin material 103 . The base film 101 is optically transparent, and the material of the base film can be polyester, polyethylene, polycarbonate, such as A-4100 or A-4300 PET film produced by Japan Toyobo. However, the base film material is not particularly limited. Any material with optically transparent properties can be used as the base film material. The raised microstructure 102 may be made of resin material or other materials. When the raised microstructure 102 is made of a resin material, the resin material forming the raised microstructure 102 and the resin material 103 between the microstructures can be the same material or different materials, such as acrylic resin, polyester resin , polyurethane, polyvinyl chloride, or silicone. The raised microstructure 102 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com