Heating control method of electric kettle

A technology of heating control and electric kettle, which is applied in the direction of temperature control using electric methods, can solve problems such as misjudgment, achieve the effect of solving the problem of low temperature measurement accuracy and saving the time of boiling water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

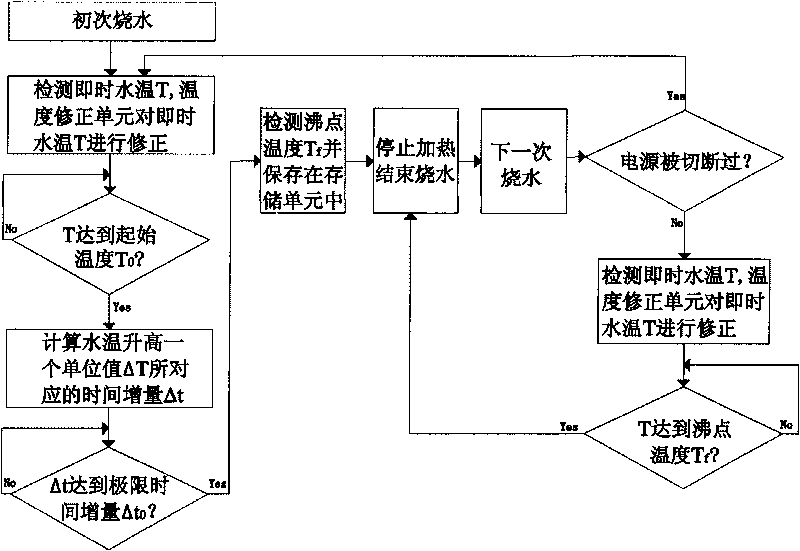

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

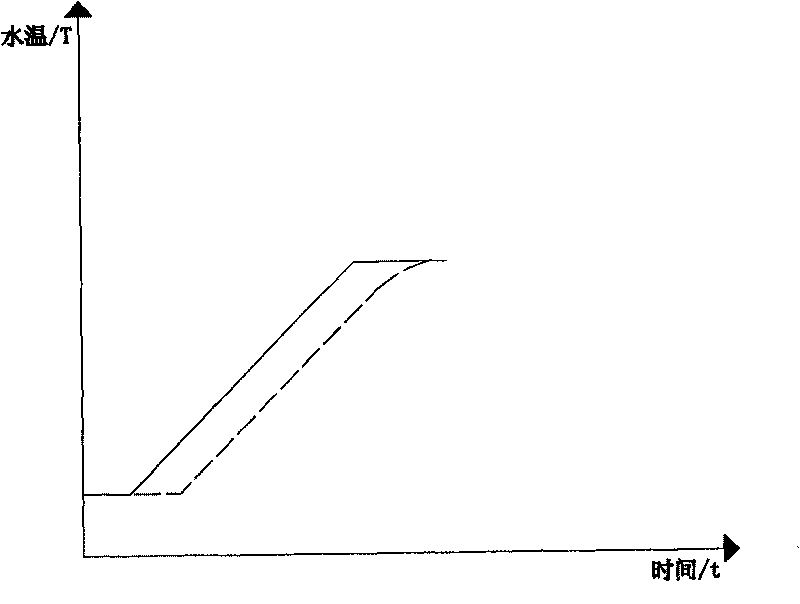

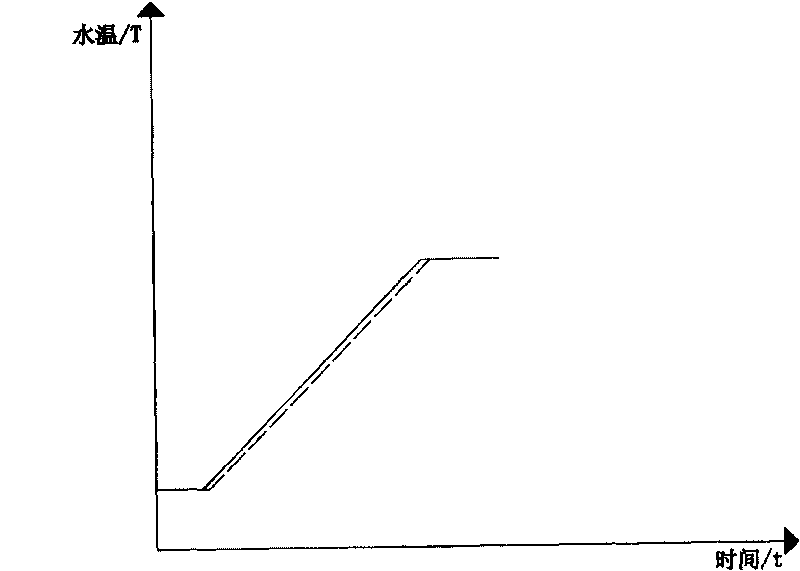

[0035] The heating control method of the electric kettle includes three stages: a preheating stage A, a heating stage B and a boiling stage C. After the heating circuit of the electric kettle is turned on, it enters the preheating stage A. Since the heating device of the electric kettle has just started to heat and boil water, the water temperature rises very slowly during this stage, and the rate of change of the water temperature is very small. As the heating time increases, it begins to enter the heating and heating stage B. At this time, the water temperature continues to rise rapidly with time, and the rate of change of the water temperature is relatively large. Immediately following the heating stage B is the boiling stage C. In this stage, the water in the electric kettle has boiled, the water temperature rises extremel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com