Halbach array external rotor of composite-structure permanent magnet motor

A composite structure and permanent magnet motor technology, applied in the field of Halbach array outer rotor, can solve the problems of inflexible selection of motor poles and magnetic coupling of composite structure motors, and achieve the effect of reducing iron loss and improving motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

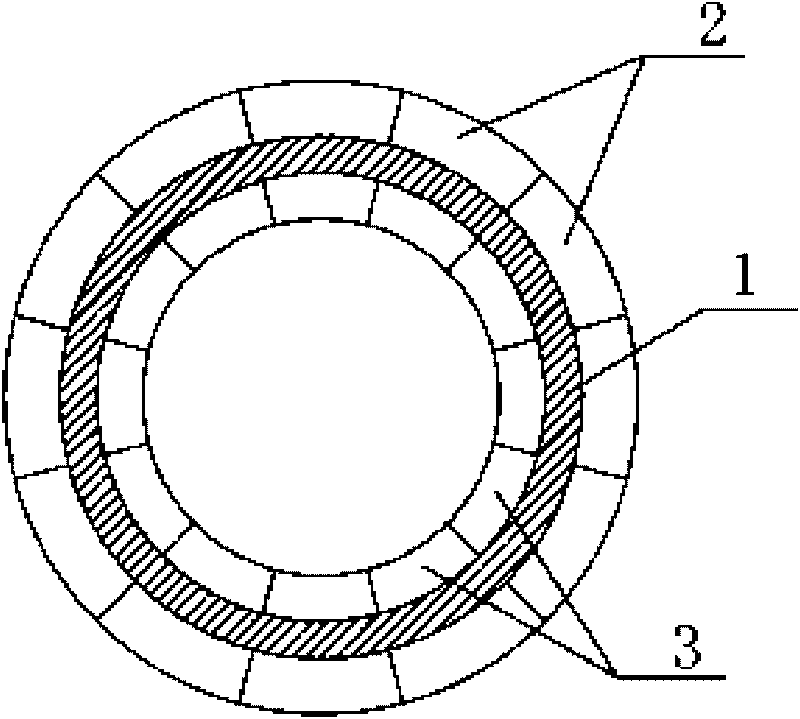

[0009] Specific implementation mode one: combine Figure 1 to Figure 7 Describe this embodiment, this embodiment is made up of rotor core 1, outer layer Halbach permanent magnet array 2 and inner layer Halbach permanent magnet array 3; Rotor core 1 is a cylindrical iron core, outer layer Halbach permanent magnet array 2 and inner layer Halbach permanent magnet array Each permanent magnet in the permanent magnet array 3 is a tile-shaped permanent magnet, and the tile-shaped permanent magnets of the outer layer Halbach array permanent magnet 2 are evenly arranged on the outside of the rotor core 1 along the circumferential direction, and the outer layer Halbach array permanent magnet 2 The inner surface of the weakened side of the tile-shaped permanent magnet is fixedly connected to the outer surface of the rotor core 1. When the outer layer Halbach array permanent magnet 2 is fixed, the side where the magnetic field is strengthened is away from the rotor core 1, and the inner la...

specific Embodiment approach 2

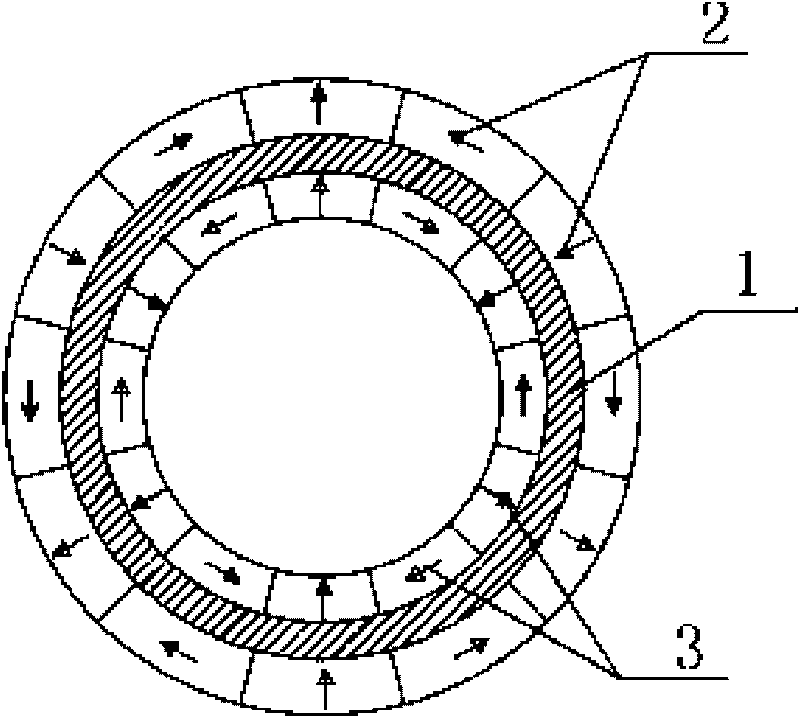

[0010] Specific implementation mode two: combination figure 2 , image 3 , Figure 4 , Figure 8 , Figure 9 and Figure 10 Describe this embodiment, the difference between this embodiment and the specific embodiment is that the outer layer Halbach permanent magnet array 2 and the inner layer Halbach permanent magnet array 3 adopt the same form of Halbach permanent magnet array, and the outer layer Halbach permanent magnet array 2 and the inner layer Halbach permanent magnet array Layer 3 Halbach permanent magnet array 3 adopts two 90° magnetized Halbach permanent magnet arrays per pole, three 60° magnetized Halbach permanent magnet arrays per pole or four 45° magnetized Halbach permanent magnet arrays per pole A type of magnet array. Other compositions and connection methods are the same as those in Embodiment 1. The more the number of permanent magnets per pole, the less the magnetic flux between the two layers of Halbach arrays.

specific Embodiment approach 3

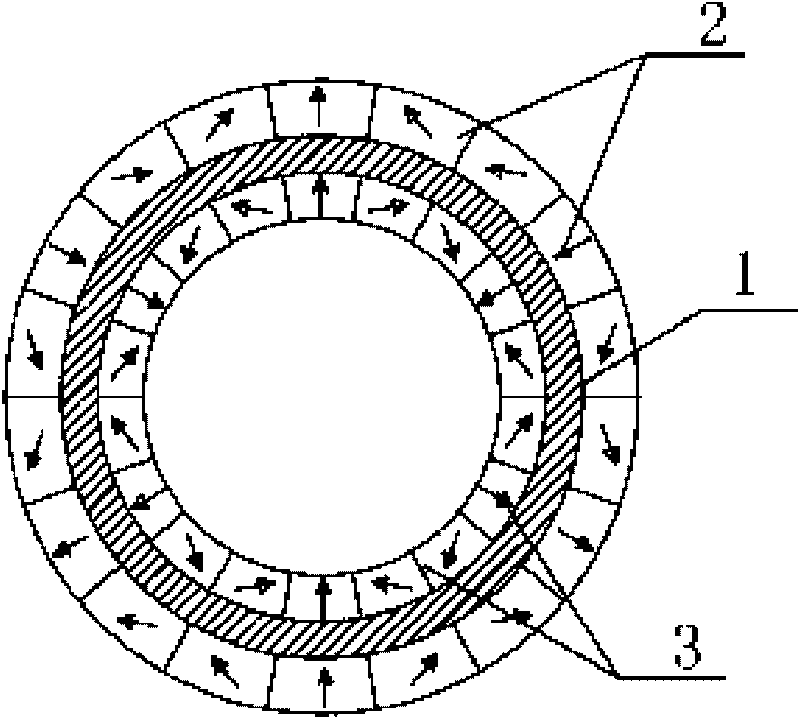

[0011] Specific implementation mode three: combination Figure 5 to Figure 7 Illustrate this embodiment, the difference between this embodiment and the specific embodiment is that the outer layer Halbach permanent magnet array 2 and the inner layer Halbach permanent magnet array 3 adopt Halbach permanent magnet arrays of different forms, and the outer layer Halbach permanent magnet array 2 and the inner layer Halbach permanent magnet array The layer 3 Halbach permanent magnet array adopts two 90° magnetized Halbach permanent magnet arrays per pole, three 60° magnetized Halbach permanent magnet arrays per pole, or four 45° magnetized Halbach permanent magnet arrays per pole. A type of magnet array. Other compositions and connection methods are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com