Initiation method of deep hole blasting for dismounting building

A technology of deep hole blasting and detonation method, applied in the field of blasting, can solve the problems that surrounding buildings and facilities cannot meet the vibration safety requirements, insufficiency, and high blasting vibration hazards, and achieves the ability to overcome the large blasting vibration hazards, large blasting volume, and explosive charge. large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiment of the utility model is further described below in conjunction with the given embodiment of accompanying drawing.

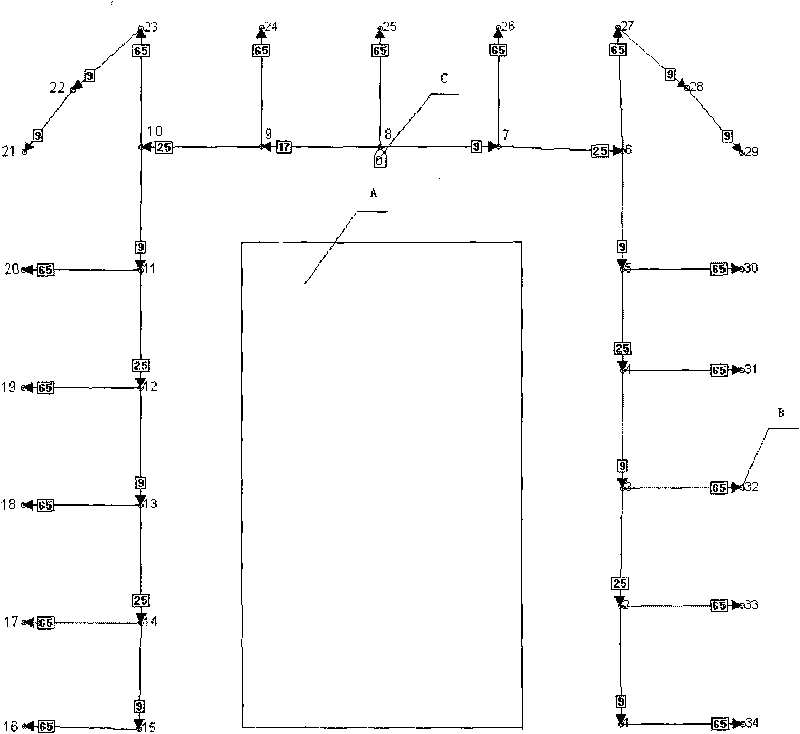

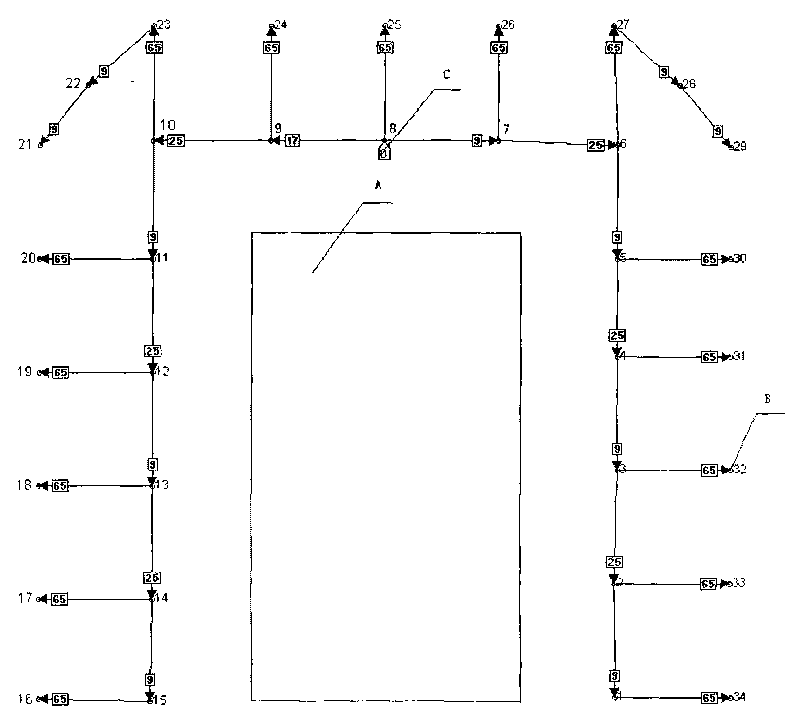

[0034] As shown in Figure 1, a kind of detonating method of deep hole blasting of demolition structure of the present invention is characterized in that carry out deep hole b hole layout design, perforation construction, carry out the time-delay design of blasting detonator detonator in deep hole 3 holes, deep hole b The construction of explosives, the delayed detonation design of the surface network detonator, the connection of the detonator in the blast hole and the surface network detonator, and the asymmetric detonation of the adjacent blast holes at the initiation point 4, the specific methods are as follows:

[0035] 1) Deep hole layout design

[0036] The deep holes 3 are located in the surrounding rock mass of the subsurface structure a, and there are 2 to 5 rows, and two deep holes b are respectively added at the four corne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com