Rolling mill changer

A technology for changing rolls and rolling mills, which is applied to metal rolling stands, metal rolling mill stands, metal rolling, etc., can solve the problems of time-consuming, labor-intensive and dangerous, and achieve the effect of convenient operation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so as to facilitate the understanding of those skilled in the art, but it cannot be used to limit the protection scope of the present invention.

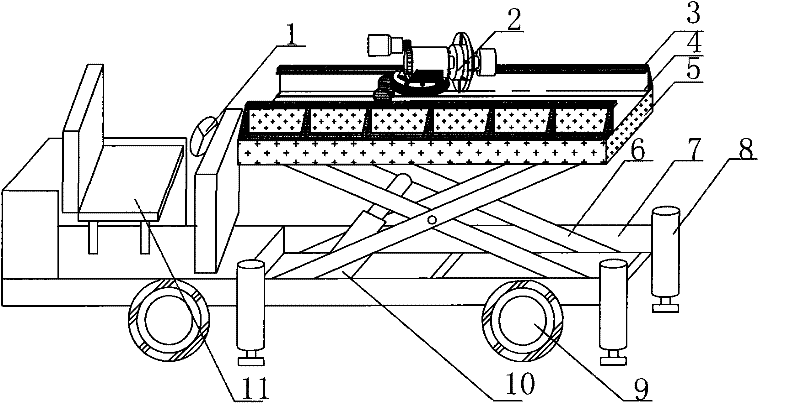

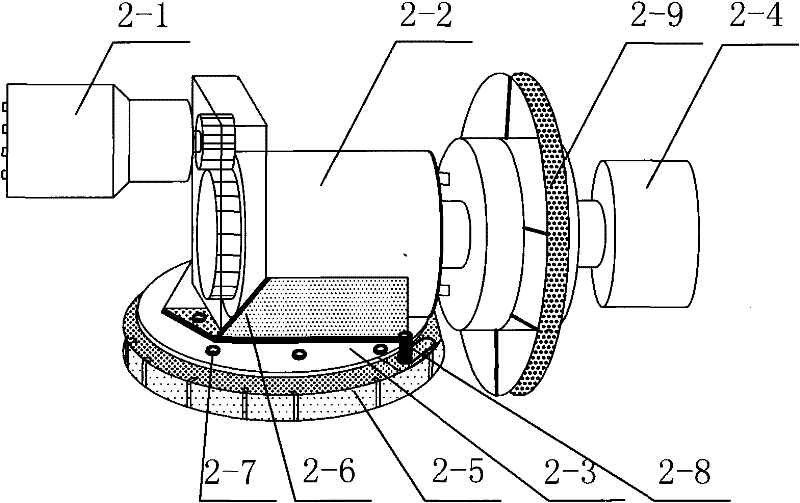

[0028] Such as figure 1 A rolling mill roll changing vehicle shown includes a chassis, a platform 5 , a lifting platform device, a feeding platform device, a walking track 4 and a roll connecting mechanism 2 .

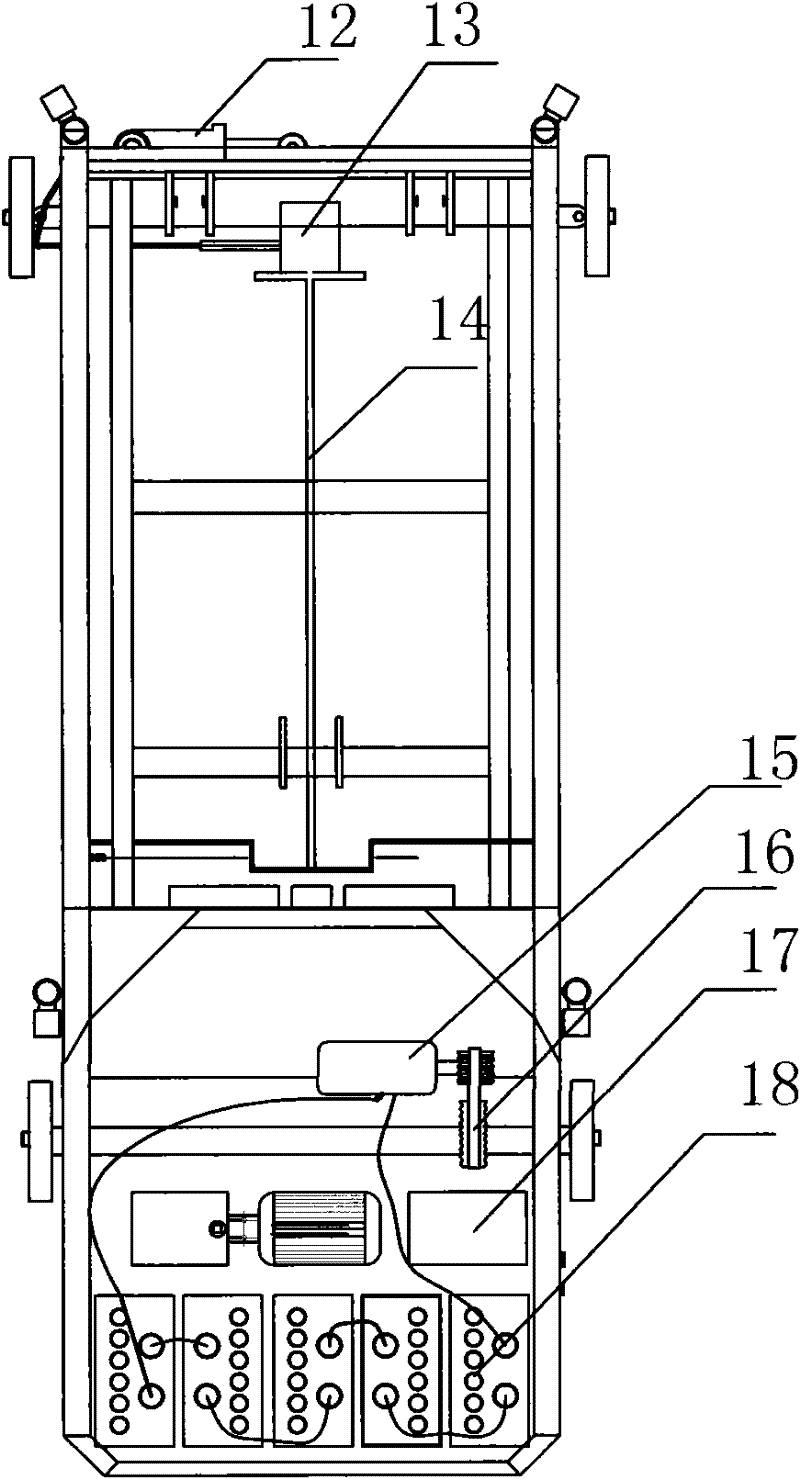

[0029] Such as figure 1 , 2 Described chassis is used for traveling on the working platform of rolling mill, and it comprises vehicle frame 7, the driver's seat 11 that is installed on the vehicle frame, steering wheel 1, electric control cabinet 19, braking system and the wheel that is positioned at vehicle frame 7 both sides 9. The braking system includes an electrically connected charger 17 , a battery pack 18 and a motor 15 , and the motor 15 is connected to the axle via a sproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com