A self-rotating quantitative filling machine for mushroom liquid

A self-rotating, filling machine technology, applied in mushroom cultivation, agricultural gas emission reduction, gardening, etc., can solve the problems of low filling efficiency and frequent operation, and achieve the effect of simple and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

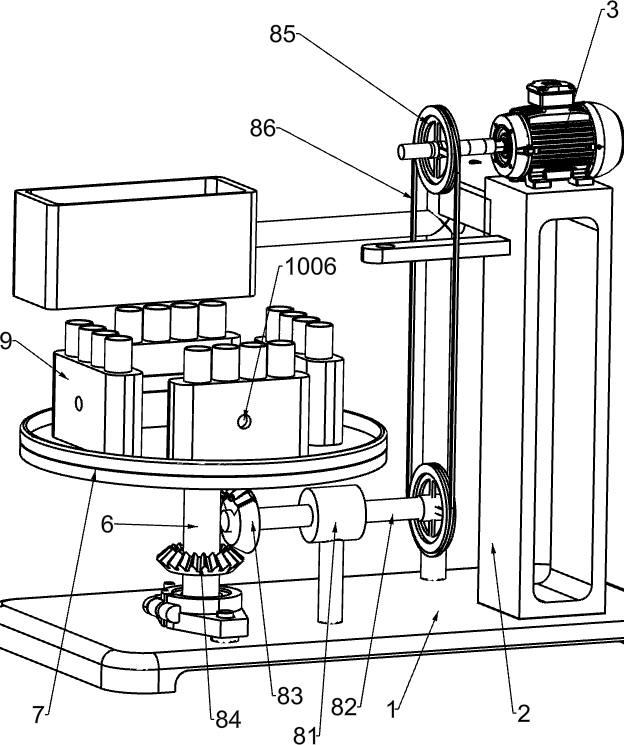

[0037] A mushroom liquid self-rotating quantitative filling machine, such as figure 1 shown, including a support 1, a support table 2, a gear motor 3, a solution tank 4, a liquid adding mechanism 5, a material replacement shaft 6, a disc 7, a replacement mechanism 8 and a test tube placement box 9. The right side of the support 1 is provided with Support table 2, a geared motor 3 is installed on the top of the support table 2, a solution tank 4 is arranged on the rear side of the support 1, and a liquid addition mechanism 5 is installed between the front of the solution tank 4 and the left side of the support table 2, and the liquid addition mechanism 5 is connected to the support table 2. The geared motor 3 is connected, the material replacement shaft 6 is rotatably installed on the left side of the support 1, the top of the material replacement shaft 6 is connected with a disc 7, the left side of the support 1 and the lower part of the material replacement shaft 6 are provide...

Embodiment 2

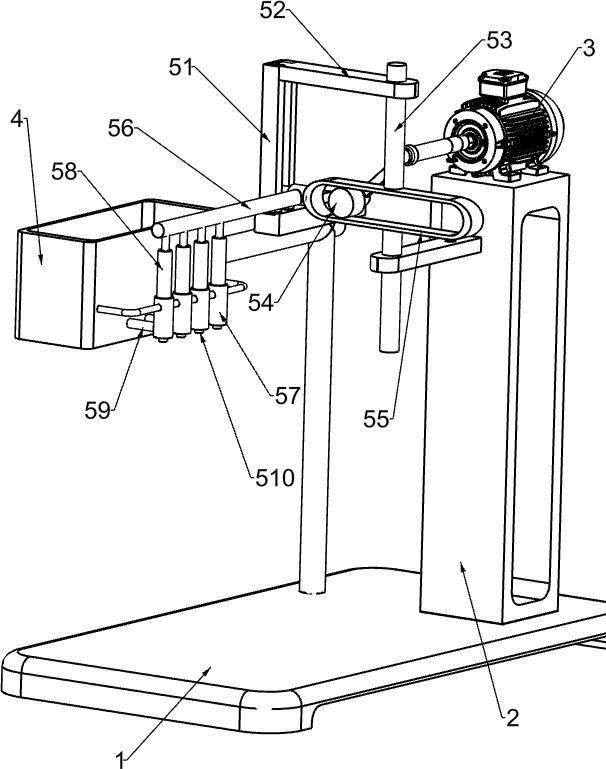

[0040] special reference Figure 1-3 As shown, the liquid adding mechanism 5 includes a vertical slide rail 51, a support rod 52, a slide rod 53, a drive shaft 54, a lateral slide rail 55, a lift rod 56, a feeding cylinder 57, a piston 58, a liquid inlet pipe 59 and a liquid outlet Tube 510, a vertical slide rail 51 is provided on the upper rear side of the support table 2, a support rod 52 is installed on the front side of the upper part of the vertical slide rail 51 and the upper side of the left part of the support table 2, and the upper support rod 52 supports the front side and the bottom A sliding rod 53 is slidably arranged between the left side of the rod 52, a transverse sliding rail 55 is installed in the middle of the sliding rod 53, a driving shaft 54 is provided on the output shaft of the deceleration motor 3, and the left side of the driving shaft 54 is located in the transverse sliding rail 55, A lift rod 56 is slidably installed in the vertical slide rail 5...

Embodiment 3

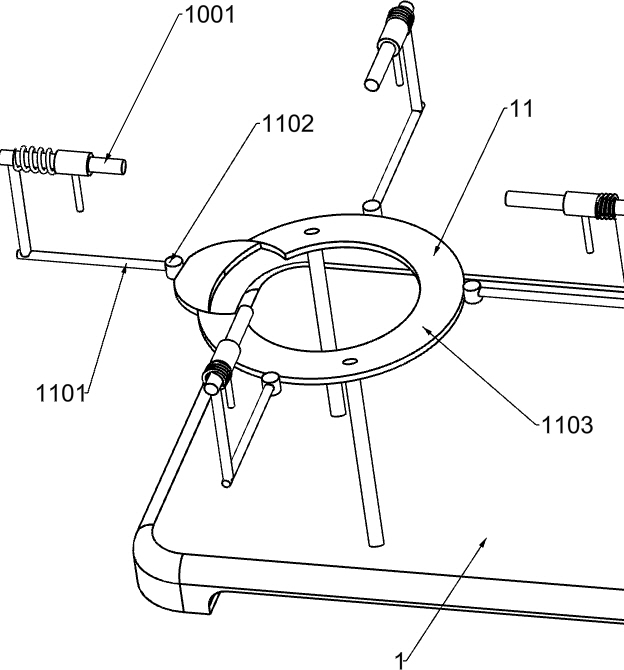

[0045] Specifically, as Figure 4-5 As shown, a fixing mechanism 10 is also included. The fixing mechanism 10 includes a cross rod 1001, a placing sleeve 1002, a fixed sleeve 1003, a moving insertion rod 1004 and a spring 1005. The cross rod 1001 is installed on the top of the disc 7, and the ends of the cross rod 1001 are provided with There is a placing sleeve 1002, the test tube placing box 9 is located in the placing sleeve 1002, the disc 7 is evenly provided with four fixing sleeves 1003, the fixing sleeves 1003 are located outside the placing sleeve 1002, and a movable inserting rod 1004 is slidably arranged in the fixing sleeve 1003, A spring 1005 is connected between the side of the fixed sleeve 1003 and the outer side of the movable plunger 1004 , the placing sleeve 1002 and the outer middle of the test tube placing box 9 have a circular hole 1006 , and the inner side of the movable plunger 1004 is located in the circular hole 1006 .

[0046] When the mushroom liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com