Wheel structure of baby stroller

A baby stroller and wheel technology, which is applied to baby carriages/baby carriages, baby carriages/cradle car accessories, motor vehicles, etc., can solve the problems of brake blocks detached from wheels, brake failure, etc., to avoid brake failure and reduce production costs , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

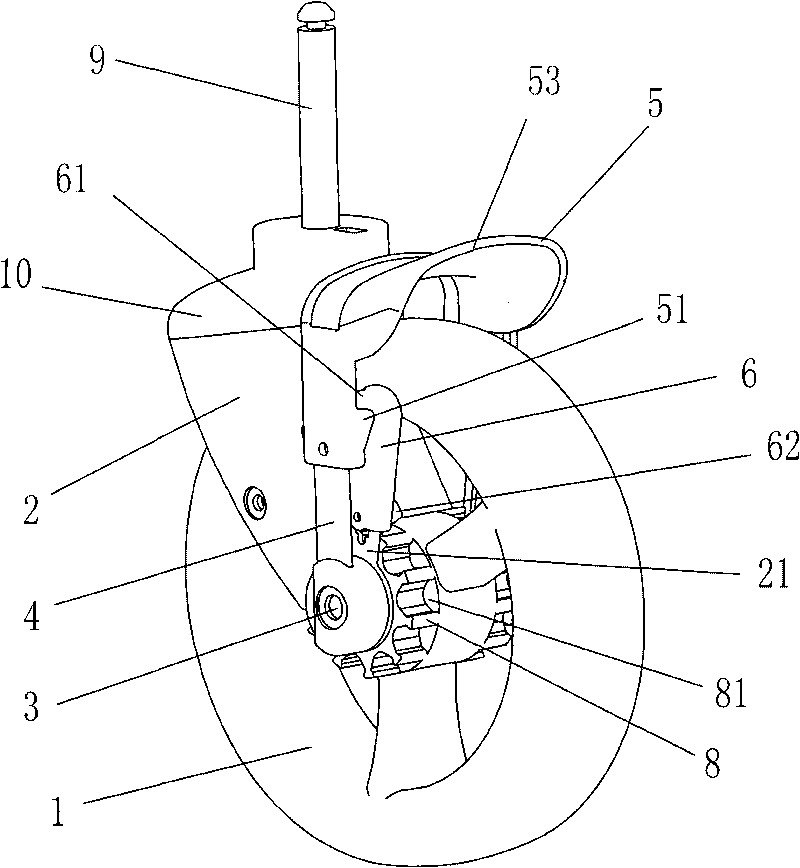

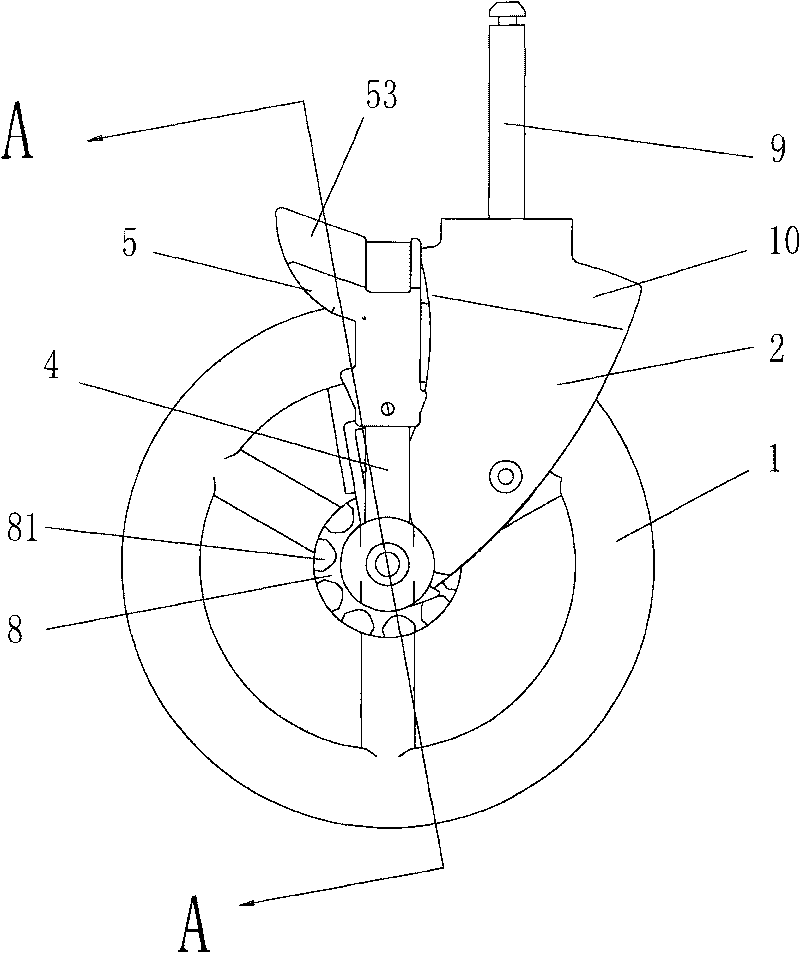

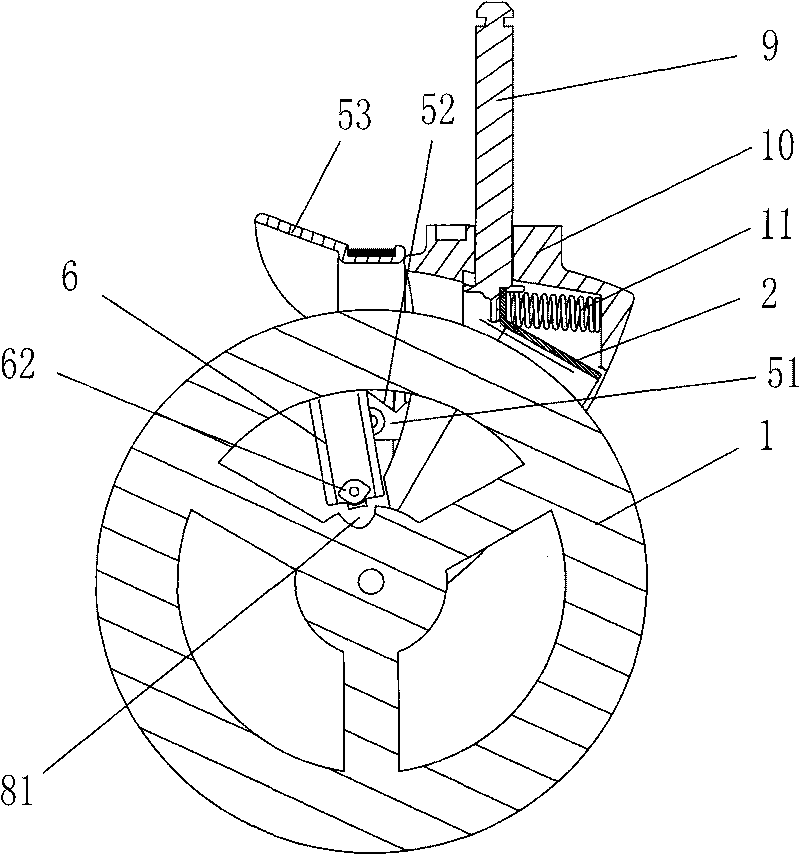

[0023] Example: such as Figure 1 to Figure 8 As shown, a wheel structure of a stroller includes a wheel 1 and a wheel fork 2, the wheel 1 is mounted on the wheel fork 2 through the wheel shaft 3, and the two sides of the wheel fork 2 are respectively pivotally connected with connecting rods 4. In this embodiment Among them, the pivot shaft is the above-mentioned wheel shaft 3, a brake pedal 5 is provided between the two connecting rods 4, the wheel fork 2 has a connecting portion 21 extending upward, and the connecting portion 21 is covered with a brake block 6, A spring 7 is connected between the brake block 6 and the connecting portion 21 , a matching portion 51 with a slope 52 is formed inside the brake pedal 5 , and a slope placed on the fitting portion 51 protrudes from the upper part of the brake block 6 . 52 above the contact portion 51, the lower part of the brake block 5 is protruded with a limit portion 52, the wheel 1 is provided with a brake disc 8 with a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com