Application of electric pneumatic braking rapid air charging device with air pressure supplement function

A technology of electro-pneumatic braking and supplementary air pressure, applied in pneumatic brakes, hydrostatic brakes, hydrodynamic brakes, etc. The cylinder provides enough compressed air, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

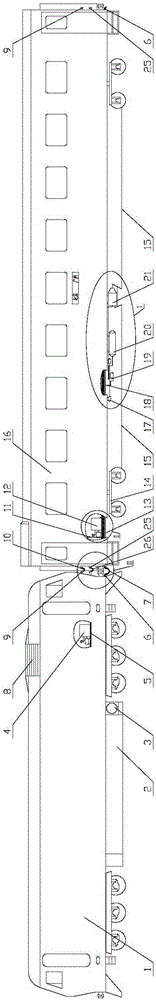

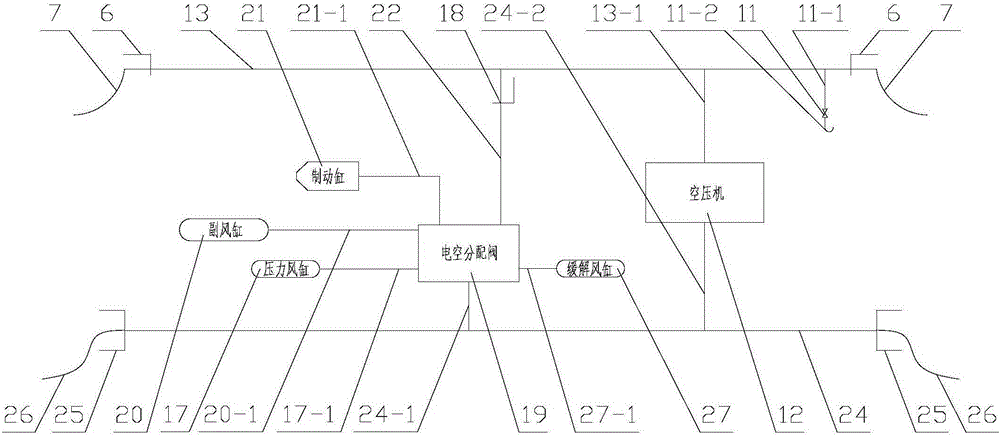

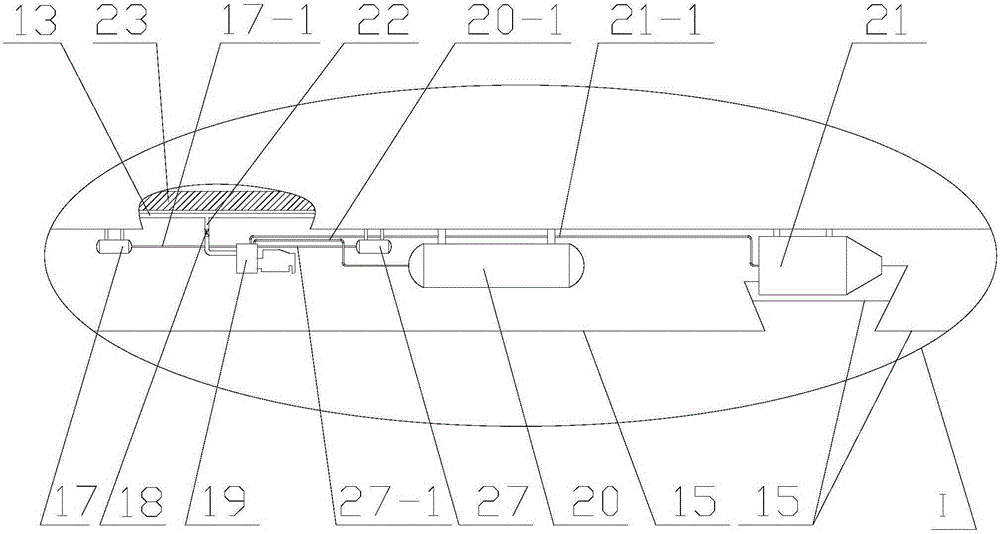

[0125] Electro-pneumatic braking speed filling device for air pressure

[0126] 1. The electro-pneumatic brake speed air filling device for supplementing air pressure includes: locomotive body 1, fuel tank 2, main air cylinder 3, locomotive air compressor 4, locomotive floor 5, angled plug door 6, brake hose 7 , resistance cabinet vent 8, power connector A9, jumper wire A10, emergency valve 11, air compressor with stable output pressure 12, brake main pipe 13, bogie 14, foundation brake device 15, vehicle body 16, pressure Air cylinder 17, cut-off plug 18, electro-pneumatic distribution valve 19, auxiliary air cylinder 20, brake cylinder 21, brake branch pipe 22, vehicle bottom beam 23, control cable 24, power connector B25, jumper wire B26, wind relief Cylinder 27,

[0127] Emergency valve 11 includes: emergency brake pipe 11-1, emergency air outlet 11-2,

[0128] The air compressor 12 with stable output pressure includes: air filter 12-1, intake pipe 12-2, air compressor m...

Embodiment 2

[0165] Application of Electropneumatic Braking Speed Air Filling Device for Supplementing Air Pressure

[0166] 1. The electro-pneumatic brake speed air filling device for supplementing air pressure includes: locomotive body 1, fuel tank 2, main air cylinder 3, locomotive air compressor 4, locomotive floor 5, angled plug door 6, brake hose 7 , resistance cabinet vent 8, power connector A9, jumper wire A10, emergency valve 11, air compressor with stable output pressure 12, brake main pipe 13, bogie 14, foundation brake device 15, vehicle body 16, pressure Air cylinder 17, cut-off plug 18, electro-pneumatic distribution valve 19, auxiliary air cylinder 20, brake cylinder 21, brake branch pipe 22, vehicle bottom beam 23, control cable 24, power connector B25, jumper wire B26, wind relief Cylinder 27,

[0167] Emergency valve 11 includes: emergency brake pipe 11-1, emergency air outlet 11-2,

[0168] The air compressor 12 with stable output pressure includes: air filter 12-1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com