Method for switching technological bogie from ground conveyer to duplex-chain conveyer

It is a technology of ground transportation and process table, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems that equipment cannot be directly compatible and robot spraying can not be realized, and achieve the effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

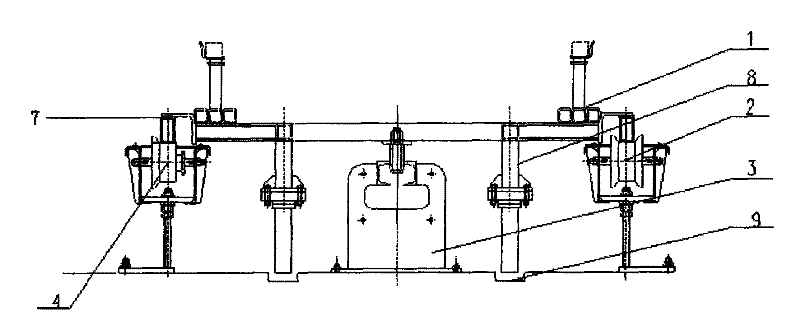

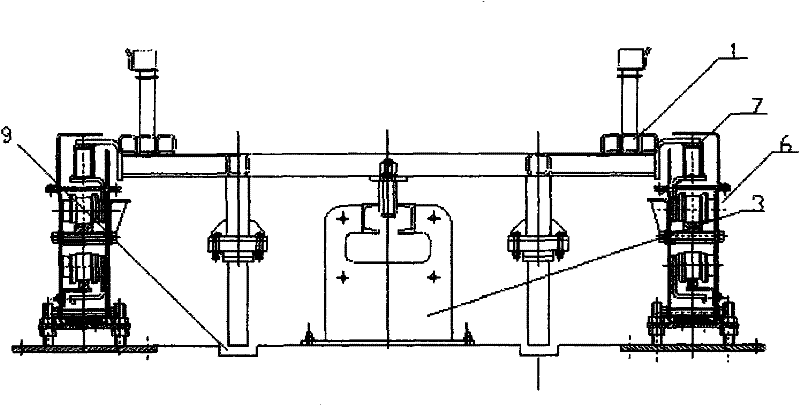

[0022] Such as figure 1 Shown, transmission shaft is not established between the roller 2 and the roller 4 on both sides of the roller bed. And in the roller bed of skid conveying system in existing paint shop, be provided with transmission shaft between the roller of both sides, this transmission shaft will produce interference with process trolley traveling wheel outrigger frame 8. In order to avoid interference, the transmission shaft is only connected to the roller 2 to provide power for the craft trolley, and the roller 4 on the other side is no longer connected to the transmission shaft, that is, there is no power input, so that the walking wheel support legs of the craft trolley can pass through the transition roller bed.

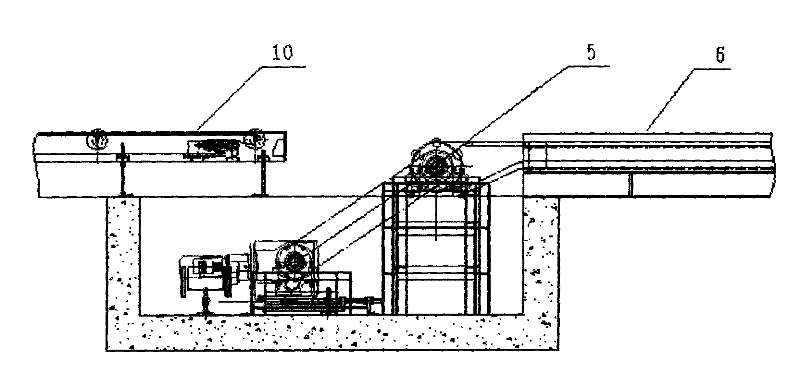

[0023] Such as image 3 As shown, the driving device 5 of the double-row chain conveyor adopts two-stage transmission, and adopts sinking treatment, that is, the driving device 5 is set between the transition roller bed 10 and the double-row chain c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com