Gapless rolling process for single-strand steckel mill

A furnace coil rolling mill, no gap technology, applied in the field of steel rolling, can solve the problems of long rolling gap between two billets, and achieve the effect of shortening the rolling gap time and increasing the hourly output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A gapless rolling process for a single-stand steckel mill. In this rolling process, before the first billet is cast, the second billet can be tapped and descaled, and follow up at a safe speed. When one piece of billet is cast, the second piece of billet enters the rolling mill for rolling, realizing seamless rolling in the steckel mill.

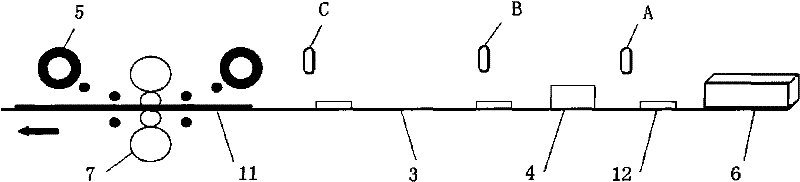

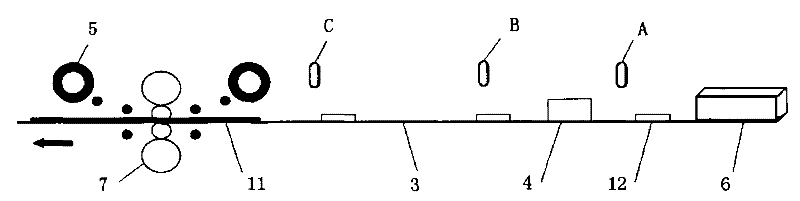

[0015] In this embodiment, two flat-rolled plate blanks with the same material shape and size are selected. The actual size of the blanks is 150*3180*8200mm, the thickness of the finished product is 25mm, and the rolling procedures are the same. Each blank is rolled for 7 passes without control. rolled. The specific process is as follows, see figure 1 :

[0016] (1) The first pass rolling of the first billet 11 ends, the rolling schedule of the second billet 12 reaches the primary interface of the rolling mill, and the heating furnace 6 begins to produce the second billet;

[0017] (2) After the second piece of billet 12 is tapped,...

Embodiment 2

[0022] A gapless rolling process for a single-stand steckel mill. In this rolling process, before the first billet is cast, the second billet can be tapped and descaled, and follow up at a safe speed. When one piece of billet is cast, the second piece of billet enters the rolling mill for rolling, realizing seamless rolling in the steckel mill.

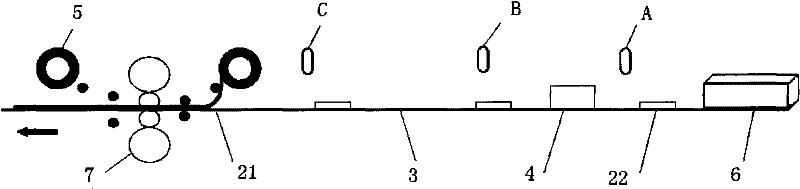

[0023] In this embodiment, two rolling plate blanks with the same material shape and size are selected. The actual size of the blanks is 150*2880*16500mm, the thickness of the finished product is 10mm, and the rolling procedures are the same. Each blank is rolled for 9 passes without control. Rolling, the 7th, 8th, and 9th pass rolling. The specific process is as follows, see figure 2 :

[0024] (1) The 5th pass rolling of the first billet 21 ends, the rolling schedule of the second billet 22 reaches the primary interface of the rolling mill, and the heating furnace 6 begins to produce the second billet 22;

[0025] (2) After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com