A cutter device for tobacco products

A cutting device, a technology of tobacco products, applied in the direction of tobacco, application, and paper cigarette manufacturing, which can solve the problems of output loss, time loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

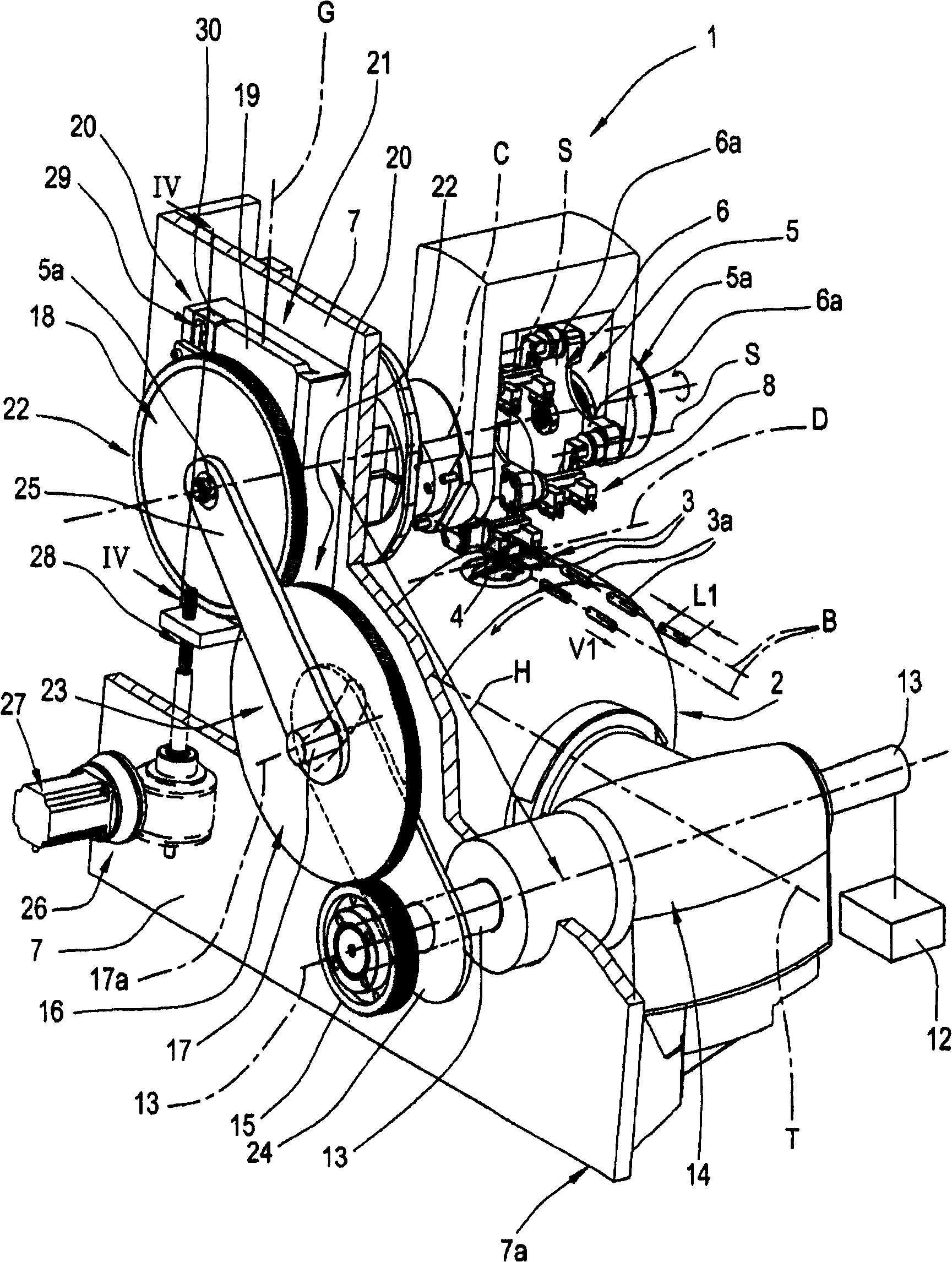

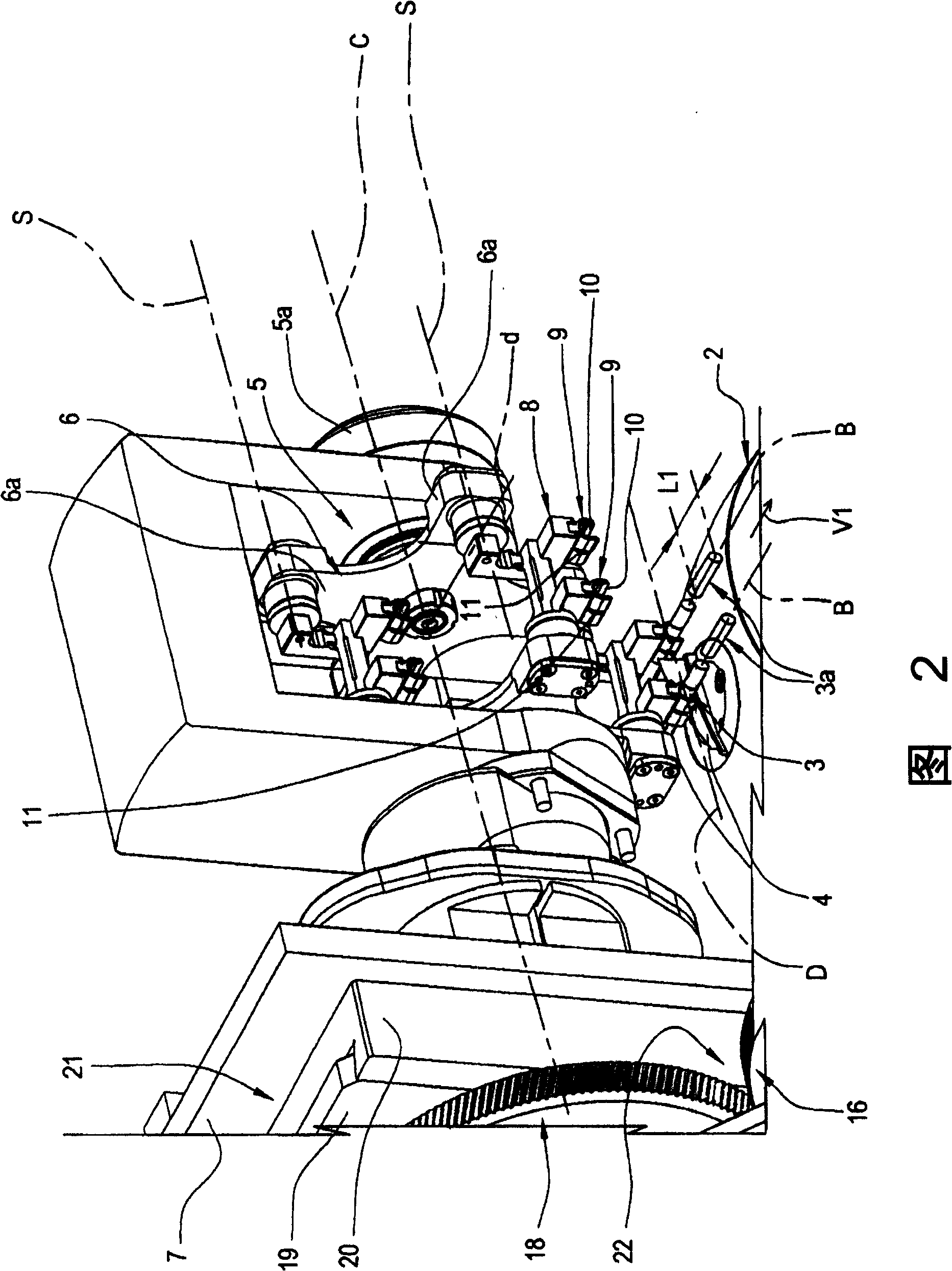

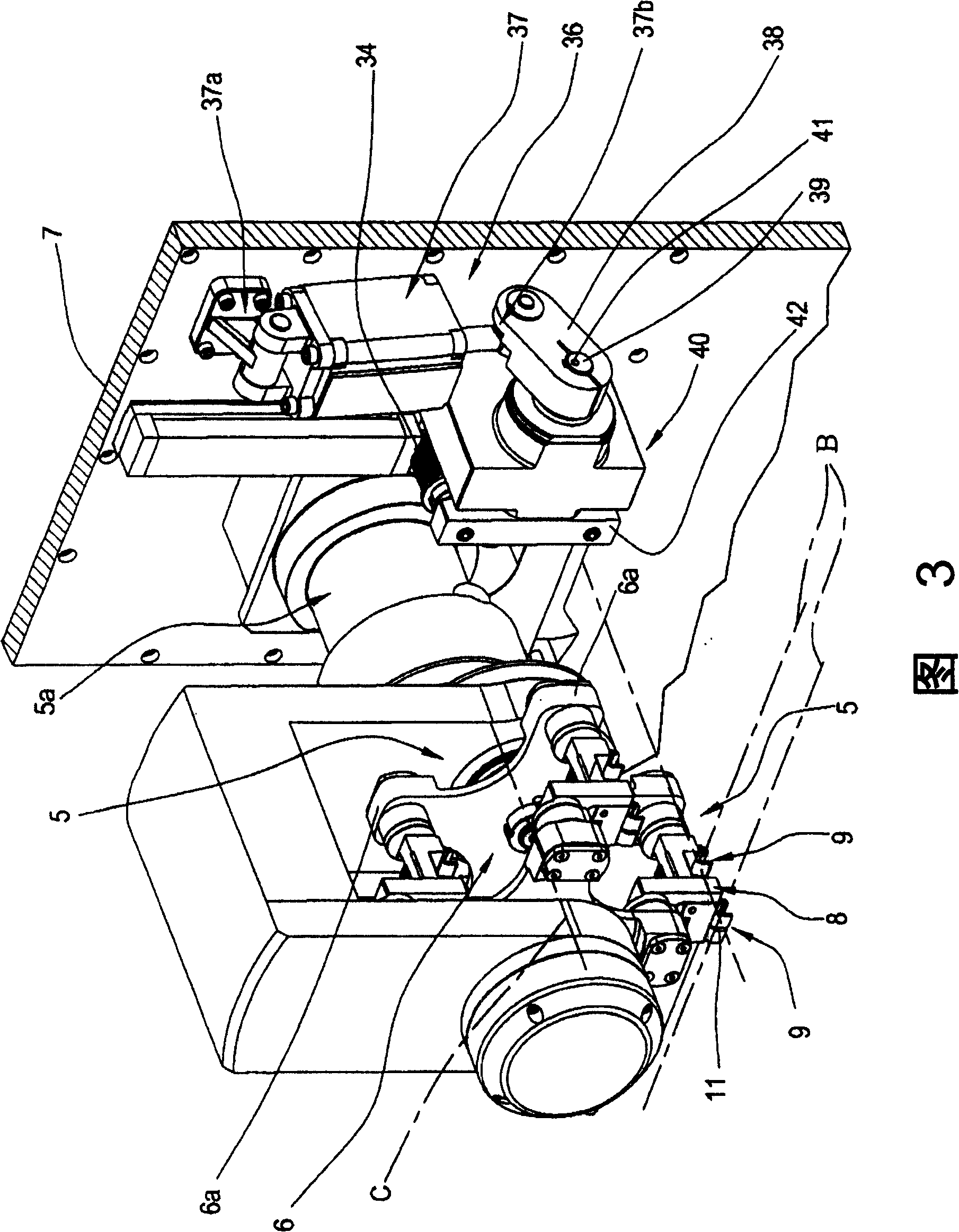

[0026] Referring to the accompanying drawings, numeral 1 generally denotes a cutting device for tobacco products according to the present invention.

[0027] The device 1 comprises a cutting drum 2, such as figure 1 As shown, the cutting drum 2 rotates in a counterclockwise direction about an axis T which is angled or skewed with respect to the feed direction B followed by at least one continuous tobacco or filter rod 3 . In the preferred embodiment in the figure, more precisely, as figure 1 2 and 2, the two continuous rods 3 advance towards the device 1 parallel to each other along the feed direction B at a predetermined and constant speed denoted V1.

[0028] The cutting drum 2 comprises two peripheral and diametrically opposite blades 4 (only one of the two blades can be seen in the figures), by which two continuous rods 3 are severed and A given angular velocity is divided into rods 3a of a predetermined length denoted L1.

[0029] The axis T of the drum and thus the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com